RAINFOREST LUMBER

Wood is one of the most important materials to mankind. It used for making houses and furniture and multitude of other things. One advantaged it has over other materials is that t is renewable, in that new trees can grow in the place of ones chopped down and they can produce more wood.

Tropical rainforests supply about one fifth of the world's industrial lumber. Logging companies claim that most of their logging is selective rather than clear cutting and that only 5 to 7 percent of wood taken from tropical forests is exported. Most the wood taken from the rainforest is used for cooking fires and other domestic uses or left smoldering or rotting on the ground by slash and burn farmers and that the most destructive logging practices are carried out by illegal loggers.

Tropical hardwoods are valued for its strength durability, texture and beauty. Only a few species have species of tree have commercial value. Relatively plentiful trees such as the Ceiba tree are often commercially worthless. Many rainforest woods have a reddish color.

Products made from tropical woods include plywood sheets for molding concrete, crates for Japanese motorcycles, coffins, railway sleepers, doors, window frames, furniture, and veneers for cabinets. Lower quality wood is made into household utensils and chopsticks, and sometimes cut up into chips used for pulp and paper. Efforts by environmental groups and higher wood costs have led to a decrease in their use as concrete forms, crates, and railway sleepers.

RELATED ARTICLES:

TROPICAL RAINFORESTS: HISTORY, COMPONENTS, STRUCTURE, SOILS, WEATHER factsanddetails.com ;

PALM OIL: USES, HISTORY, AGRICULTURE AND PRODUCTION factsanddetails.com ;

PALM OIL BUSINESS: PRODUCERS, COMPANIES, IMPORTERS factsanddetails.com ;

PALM OIL AND RAIN FOREST DEFORESTATION factsanddetails.com ;

RAINFOREST DEFORESTATION: RATES, RESULTS AND ALARM factsanddetails.com ;

CAUSES OF RAINFOREST DEFORESTATION factsanddetails.com ;

AMAZON DEFORESTATION factsanddetails.com ;

DROUGHT AND FIRE: IS THE AMAZON DRYING OUT? factsanddetails.com ;

COMBATING DEFORESTATION AND EFFORTS TO SAVE THE RAINFOREST factsanddetails.com

Websites and Resources: Rainforest Action Network ran.org ; Rainforest Foundation rainforestfoundation.org ; World Rainforest Movement wrm.org.uy ; Wikipedia article Wikipedia ; Forest Peoples Programme forestpeoples.org ; Rainforest Alliance rainforest-alliance.org ; Nature Conservancy nature.org/rainforests ; National Geographic environment.nationalgeographic.com/environment/habitats/rainforest-profile ; Rainforest Photos rain-tree.com ; Rainforest Animals: Rainforest Animals rainforestanimals.net ; Mongabay.com mongabay.com ; Plants plants.usda.gov

Valuable Rainforest Woods

Ebony is a dense black-dark brown hardwood that comes from several species in the genus Diospyros native to rainforests. Species of ebony include Diospyros crassiflora (Gabon ebony), native to western Africa; Diospyros ebenum (Ceylon ebony), native to southern India and Sri Lanka; and Diospyros celebica (Sulawesi ebony), native to Indonesia. The latter is prized for its luxuriant, multi-colored wood grain. Mauritius ebony, Diospyros tessellaria, was exploited by the Dutch in the 17th century. Ebony was used by the ancient Egyptians. Today it is used mostly to make musical instruments such as oboes and clarinets, guitar bodies and black piano keys. [Source: Wikipedia]

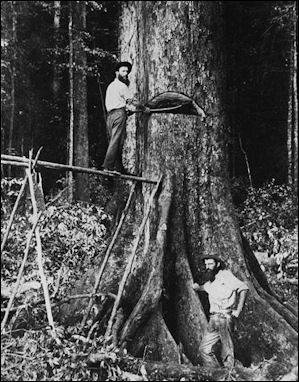

felling a tree on the Atherton

Tableland Australia 1890-1900Mahogany is another valuable wood tree found in the rainforest. Scott Wallace wrote in National Geographic: It “is the crown jewel of the Amazon, soaring in magnificent buttressed columns high into the forest canopy. Its rich, red grain and durability make it one of the most coveted building materials on Earth, favored by master craftsmen, a symbol of wealth and power. A single tree can fetch tens of thousands of dollars on the international market by the time its finished wood reaches showroom floors in the United States or Europe. After 2001, the year Brazil declared a moratorium on logging big-leaf mahogany, Peru emerged as one of the world’s largest suppliers. The rush for “red gold,” as mahogany is sometimes called, has left many of Peru’s watersheds—such as the Alto Tamaya, homeland of a group of Ashéninka Indians—stripped of their most valuable trees. The last stands of mahogany, as well as Spanish cedar, are now nearly all restricted to Indian lands, national parks, and territorial reserves set aside to protect isolated tribes. [Source: Scott Wallace, National Geographic, April 2014]

Four kinds of rosewood grow in Brazil: “Jacarandá” is arguable the best wood in the world for making cabinets; one is nearly black with purple lines; the others are "striped like a tiger on a rich tawny to dark red ground." Rosewood oil comes from the Brazilian laurel trees grown in the Amazon basin. This important ingredient is slowly being replaced by synthetics.

Malagasy rosewood (Dalbergia andapensis) — reddish and superbly grained — from Madagascar is among the world’s most sought-after timber, especially since Asian sources of similar trees have been depleted. Critically endangered, it highly valued timber used in the production of fine furniture and musical instruments. In China, the finished wood is primarily used to make replicas of antique furniture, and musical instruments, some for export. It is estimated that 52,000 tonnes of rosewood and ebony were logged in north-east Madagascar in 2009. . According to Business Insider: “For thousands of years, agarwood has been known as "The Wood of the Gods." First-grade agarwood can cost as much as $100,000 per kilogram, making it one of the most expensive raw materials in the world. Aquilaria malaccensis is a tree native to the rainforests of southeast Asia. The healthy heartwood inside Aquilaria trees is pale, odorless, and worthless. In order for this tree to produce any agarwood, it must first become infected with mold and there is process ro do this. [Source: [Source: Business Insider Video, August 27, 2020]

Another kind of agarwood, aquilaria sinensis, was once grown in plantations across its native southern China, including parts of northern Hong Kong, as far back as the 960-1279 Song Dynasty to provide the raw material for joss sticks shipped as far afield as the Arabian Peninsula. The trade died out as Hong Kong's economy modernized and the city became a center for finance, not fragrance. You can still find agarwood in Hong Kong. [Source: Associated Press, December 24, 2014]

The Aquilaria species is listed under the Convention on International Trade in Endangered Species of Wild Fauna and Flora, which restricts its legal trade. At least 340 people were arrested between 2005 and 2014 for illegal felling of incense trees, according to the Hong Kong government, which is planting 10,000 saplings a year to help the species survive.

Logging Methods

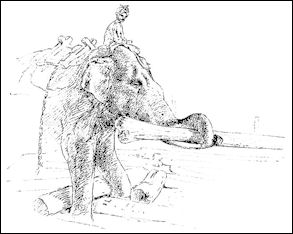

Elephant lifting teak logs There are two broad categories of logging: 1) clear cutting, in which all the trees are cut down and cleared from a given areas; and 2) selective logging, in which only a few highly valued trees such as mahogany or ebony are taken and the rest of the forest relatively intact.

These days the long industry is highly mechanized. Lumberjacks with axes and saws are largely a thing of the past. In many logging operations the primary tools are bulldozers that are used both to knock the trees and drag them from the forest.

Loggers often live in camps near were the trees are cut down since most of lumbering sites are far from where people live. Away from the families for months at a time, the loggers live in tents or shelters and eat in a kind of mess tent. To get to the camps and the logging sites roads are built, primarily using bulldozers. Sometimes lumber camps are set up and trees felled only a day after a road has been bulldozed through.

Selective logging isn’t always what it claims. Large swaths of forest are often destroyed to get te three of four trees per hectare. Heavy machinery knocks down smaller trees, trees linked together by vines and damages the soil and creates erosion. Road building and the use of bulldozers and other heavy machinery to pull out the trees also damages the forest and provides access to the forest for illegal loggers and slash and burn farmers.

By some measures between 45 and 74 percent of the trees left behind after selective logging have damaged or destroyed. From the air the rainforest doesn’t look too badly disturbed, just dirt roads and occasional jagged wounds left behind by tractors and bulldozers. In some places that have been clear cut or are earmarked for plantations or ranches the valuable hardwoods are harvested and the rest of the forest is set on fire after it has dried. In this way, hundreds are acres of former trackless forests can go up in smoke in a matter of hours.

Cutting Down Trees and Harvesting Logs

Most lumbermen that do the actual cutting use power saws. They often have certain specialties. Some men cut the trees down. Other cuts away the branches and others still cut the trees in standard size logs. Logging in the rainforest is often dangerous work. Often the trees are felled at such a rapid rate that it is easy to get struck if one is not careful.

Before a tree is cut down it is notched to control the direction of the fall, so the falling tree isn't damaged and it doesn't damage other trees in the forest. The men who do this are so skilled they can make a tree fall with in one or two feet of the desired fall area. Sometimes ropes are used to guide the tree down. While a tree is being cut, wedges are placed in the cut to keep the tree from pinching the saw and kerosene is dripped on the saw chains to keep them from binding.

Clearing is largely done by bulldozers. Describing a timber crew at work, Richard Conniff wrote in Smithsonian magazine, "The bulldozer deftly undercuts the left side of the tree, then moves to right, where a strangler leans heavily on a tree-seize areal root. The operators' hands move skillfully among the levers, going from forward to reverse, adjusting the angle of the blade, accelerating into the root. It is hard not to admire his ability. He get paid about $5 a day."

elephant dragging logs "Roots crack apart, and after 30 passes the tree shudders and begins to give way," Conniff wrote. "The operator glances up and sees the strangler starting to fall. He throws his bulldozer in reverse, and the fabric of plant life begins to rip apart in front of him. Vines separate, branches split, leaves shower down with it, until the whole canopy seems to come crashing to earth. Light floods in the ensuing silence.”

The trees are cut into logs that are a length that can be handled by machinery. The logs are picked up and moved in the forest with a skidloader, a machine that looks like a threaded bulldozer with a pair of claws that can pick up the logs, or a tractor that drags the logs through the forest in process called snaking.

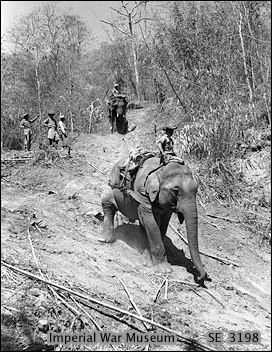

In Asia much of snaking has traditionally done by elephants. See Asian Elephants and Logging Below

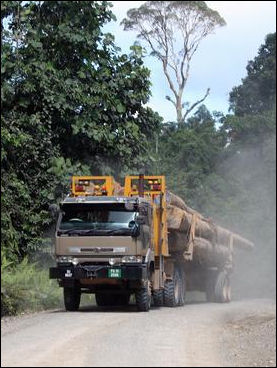

Transporting the Logs

Large logs are often moved out the of the forest with overheard cables in a process called skidding. Setting up cables, called a skyline, is one of the most important jobs. First tall trees are selected. The tree closest to the landing area is called the head spar. The one closest to the cutting area is called the tail spar. High-lead logging uses only one spar and the logs are pulled on the ground.

Setting the spars is a very dangerous job. A high climber climbs the tree with a leather strap and boot spikes and cuts off the top of the tree called the crown. When the crown is cut and the high climber has to hang on for dear life because the tree shakes so violently There is danger the crown could fall on him. Afterward the skyline is attached and the spar is braced with cables.

Tractors outfit with special hoists lift the logs to the cables, where the logs are moved with a block and tackle arrangement. The cables that descend from the skyline have nooses that hold the logs. Diesel or gasoline engines provide to pull the block and skidding line. Other engines are used to pull the logs within reach of the noose.

A large crew of skilled workers is necessary to operate a run this kind of logging operation. Workers are needed to se the nooses around the logs, machines, unhook the logs from the nooses, and direct the operation. If one person screws up he could seriously injure himself or members of his team

At their pick up point the logs are be moved by trucks or floated down rivers. These days the logs are often moved directly from the logging sites by truck to the mills with minimal use of cables. The most cost effective way to move large amounts of logs is to float them down rivers. When the logs reach a mill they are often stored in a pond to keep them from deteriorated. They are easy to sort when wet.

One of the main problem with logging is that the logging roads are used my poachers, bush meat hunters, illegal loggers and peasant farmers to gain access to the forest. Roads are also built by mining and oil companies in search of fossil fuels and minerals.

Asian Elephants and Logging

elephants stack logs Elephants are very important in the teak business. They are skilled professionals that are trained by their Karen mahouts to work alone, in pairs or in teams. One elephant can usually drag a small log on land or several logs through water with the chains that are harnessed to its body. Bigger logs can be rolled by two elephants with their trunks and lifted off the ground by three elephants using their tusks and trunks.

It reportedly takes 20 years to train an elephant for the logging in the forest. Such animal worth as much as $9,000 a piece, and earn $8 or more for a four-hour day. Female elephants with short tusks are used for pushing things. Males with long tusk are good for logging because their tusks enable them to pick up logs. the tusks get in the way if the push something.

Work elephants used to hoist logs onto trucks that usually carry the logs to rovers, where the logs are float to mills. Men saw teak logs in the water and water buffalo, that kneel on command, pull the logs out of the water and push them onto carts.

Elephants are still used in Burma to move teak logs. Drivers, called oozies, prepared their mounts with a pick-ax-like tool called a choon. If necessary the elephants can be transported from place to place in trucks or trailers pulled by trucks. Elephants used in illegal logging are sometimes brutally used.

Elephants are a good alternative to clear cutting because they can be used to select only the species of tree that are needed, they don't need roads and they can maneuver through all kind of terrain. Because elephants in Thailand may be out of work soon as the teak forests are depleted, I say transfer them to the Pacific northwest were they can used as alternative to the clear cutting used there.

Elephants are cheaper and most frailty than tractors and damaging forest roads. "Instead of hauling away heavy green logs with bulldozers and tractor skidders, which scar erosion-prone hillsides," wrote Sterba, Burma uses elephants to pull their lighter dried logs to rivers on which they float to staging areas for exporting processing." [Source: James P. Sterba in the Wall Street Journal]

Lumber and Paper Industries

forestry elephants in India At the mill the logs are first blasted with powerful jets of water to remove gravel and dirt or anything else that might damage the saws. The bark is trimmed off and the log is cut lengthwise into boards. Care is taken to avoid knots and cut the wood with a good gain.

The timber is sawed into boards with a variety of different kinds of saws, depending the job and the kind of lumber desired. Plywood is made with special, rotating "peeling" machines that cut logs in such a way can be unrolled like a roll of aluminum foil. After the wood is cut it is dried, planed smooth and sometimes treated so it doesn't warp and is resident to water. Finally the lumber is graded and stacked to be shipped.

Paper is made of fibers that are mixed together when wet and bond together when dry. Soft-wood coniferous trees such as pine and spruce are often used to make pulp and paper. A variety of chemicals are used, depending in the wood used and the quality of paper and type of paper product desired.

To make paper, logs are cuts into chips, about a half inch to 1½ inches in size, which are ground up and dumped in large vats with chemical solutions that turn desirable cellulose fibers into pulp and dissolve the undesirable wood substances which are removed. The process takes from 2 to 35 hours, depending on the desired paper quality. To make sulfite pulp, which is used for a variety of writing and book paper and tissue papers, the chips are mixed with sulfuric acid. Newsprint are about one forth sulfite purple and three fourths grounded pulps. A liquid chemical called lignin is produced in the paper-making process, and this can be used as a fuel for electric power generation. The pulp industry requires a lot of energy.

American-style soft toilet paper is bad for the environment environmentalists say. To make it soft and fluffy requires chopping down trees, in some cases from virgin rain forests in Brazil and Indonesia. The long fibers from old trees produce a smoother and more supple web and this translates to softer toiler paper. Toilet paper made with recycled paper — which has shorter fibers — is stiffer and courser. Environmental groups such as Greenpeace have been trying to get toilet paper makers like Kimberly-Clark to use more recycled paper in their products. In recent years executives with the company have said they will try but have their customers to worry about.

Logging Companies

Logging companies usually contact with governments to harvests timber on public lands, generally granted as a concession between one and 25 years, The life cycle of many tropical trees is over 75 years. This means that logging companies operate on short harvest schedules and are less concerned about the forest’s future than if they owned the land or held longer term leases.

Logging regulations relating to volume of timber harvested are easy to get around because lack of resources and manpower to enforce the rues.

The logging companies often make a killing while the money earned by the government is often minimal. Sometimes the timber operations in the rainforest are subsidized from foreign governments and development bank and would go out of business if the money dried up.

Companies from Malaysia, Indonesia, South Korea and Singapore are extracting timber from the Amazon for markets mainly in Europe, the United States and Japan. In 1996, Asian companies invested more than $500 million in the Brazilian timber industry and control 30 million acres in Brazil, Suriname and Guyana.

People in western countries who buy tropical woods bear some responsibility for deforestation caused by logging.

Market for Tropical Wood

The main importers of tropical woods in Asia are China, Japan, South Korea and Taiwan. New markets have opened up for tropical woods in China. Japan has traditionally been the world's largest consumer of tropical rain forest wood. In the 1980s and 90s much of the rain forest in Borneo cut down at that time was done so to meet the demands of the Japanese market. In the 1980s Japan received the vast majority of its tropical timber from Sarawak and Sabah in Malaysia. These days much of the timber imported to Japan with a Malaysian label is actually from trees that have been illegally logged in Indonesia. Japan provided aid money to build roads in rainforest area that were later exploited by Japanese timber companies.

The furniture industry in China gobbles up large amounts of Chinese timber as well as illegally-logged tropical rain forest timber from Indonesia and other places. The use of disposable chopsticks uses up 1.3 million cubic meters of timber a year according to China’s environment ministry.

Between the mid 1990s and mid 2000s China went from being a country that imported much of its wood products to one of the world’s leading exporters of furniture, plywood and flooring. China is also a leading consumer of paper. While many paper products are made with recycled paper China still has built a number of new pulp mills and in the future they will need trees to keep them going.

Chinese demand for wood is consuming forests around the globe. The rain forest of the Congo and Cameroon in central Africa, the Amazon basin and the islands of Indonesia are all being heavily logged to supply China’s growing demand for wood and its rapidly-growing furniture industry.

Suzano SA, the World’s Biggest Pulp Producer

Suzano Paper and Pulp is world’s the biggest producer of hardwood pulp. A Brazilian company, with a presence in over 80 countries, it is headquartered in Salvador, with administrative office in São Paulo and others offices in Buenos Aires, Fort Lauderdale, London, Shanghai and Signy-Avenex. [Source Wikipedia]

The company is a leader in the paperboard market in Latin America. It is among the 10 largest producers of market pulp and the largest producer of eucalyptus pulp (paper) in the world. This achievement was possible thanks to the growth cycle completed in 2007, which paved the way for increased production capacity. 2017 saw a record volume of 1.2 million tonnes of paper production and 10.8 million tons of pulp production.

China is the largest commodity buyer and accounts for 43 percent of Suzano’s pulp. The company acquired Kimberly-Clark assets in Brazil and is an active voice against the Amazon deforestation in Brazil. Suzano Chief Executive Office Walter Schalka told Bloomberg We need to have zero illegal deforestation. That is critical for the world. [Source: Dayanne Sousa, Bloomberg,, May 9, 2023]

Asia Pulp Accused of Clearing Rain Forests

In July 2010, Greenpeace has accused one of the world’s largest pulp, paper and palm oil companies of aggressively clearing Indonesian rain forests and throwing into doubt a landmark billion-dollar deal that aims to fight climate change by curbing deforestation. In a report Greenpeace accused a subsidiary of the Indonesian family conglomerate Sinar Mas of secretly planning a massive expansion of pulp mills and cutting down essential forests, including habitats for endangered tigers. [Source: Aubrey Belford, New York Times, July 5, 2010]

Aubrey Belford wrote in the New York Times, “The Greenpeace report says that an internal 2007 document shows that Asia Pulp drew up plans to significantly increase its pulp mill capacity to 17.5 million tons a year from 2.6 million tons. The report also said that Asia Pulp had sought more than a million hectares in new concessions to meet this demand. In the Sumatran provinces of Riau and Jambi alone, the company sought 900,000 hectares, or 2.2 million acres, more than half of which was granted, Greenpeace says.” “What is actually happening in the field is they keep expanding because their timber concessions are not enough to supply their mills,” Bustar Maitar, Greenpeace’s lead forest campaigner in Indonesia, told the New York Times. Greenpeace also charges that much of the land set aside and cleared overlaps with endangered-species habitats.

Greenpeace also charges that Asia Pulp has cleared peatlands more than three meters, or about 10 feet, in depth. In Indonesia, the clearing of such deep peatland is illegal because the land, which is made up of semidecomposed vegetation, releases huge amounts of greenhouse gases when burned or drained. The Greenpeace report goes on to criticizes several multinational companies, including Wal-Mart, Hewlett Packard, Carrefour and KFC, for buying from Sinar Mas and urges them to suspend dealings with the company.

Asia Pulp’s sustainability chief, Aida Greenbury, denied that the company had confidentially made any such expansion plans. “To support production of 15 million tons of pulp a year is just impossible,” Mrs. Greenbury said, because the company would not be able to harvest enough wood to feed the mills. “I don’t know how they came up with 15 million tons.” She added, “It’s impossible to plan expansion of pulp mills secretly because we need to get approval from the local government, the central government, everything else. Mrs. Greenbury said that Asia Pulp did not use wood from forests it deemed to be of “high conservation value,” which included deep peat and major endangered-species habitats. The company takes around 85 percent of its wood from plantations, she said, with the rest coming from degraded land or lower-value forests. ”

logging in colonial Indonesia

Environmentally-Friendly Logging?

The aim of forest management is log sustainably so the amount of timber that is taken out is offset by trees that are planted and regenerated. Profits of s sustainable logging are 20 percent to 50 percent lower than unsustainable methods in the short term but the damage it causes can last hundreds of years. Less than 0.02 percent of the world's tropical rainforests are managed sustainable for timber.

When you fly over the canopy of rainforest that have been sensitively and selectively logged you can't even tell the loggers have been there because only small fraction of the trees have been taken. African mahoganies, for example, are generally found in concentrations of only one per hectare. Removing them causes a loss of 5 to 10 percent of the canopy, not enough to disturb the basic structure of the forest. Mahoganies can be logged in this way because th high prices they fetch justifies the money spent on careful logging and expensive transportation methods

Ideas suggested to promote sustainable logging include: 1) granting logging companies long terms leases so they are interested in the long term welfare of the forests; 2) adding taxes to timber prices to pay for reforestation programs; 3) encouraging producers countries to make more finished goods so they can make a larger profit and have a stronger interest in preserving the resources. 4) using elephants and buffalo, which cause less damage than heavy machinery; 5) building fewer roads; and 6) using methods like directional felling, cutting vines that bind trees together before the trees are felled, and cutting logs before they are removed from the forest to cut down on damage and disturbances to the forest. These and other measures can reduce damage to the forest by 50 percent or more.

Reduced-impact logging (RIL) is a careful method of timber harvesting in which profitable trees are taken with minimal damage to other trees and the forest floor. Developed in Australia, RIL is much more expensive and time consuming that clear cutting but the forest can recover to it natural condition in 10 years as opposed to 100 years.

Home Depot and Ikea are participating in a program in which wood is certified by the Forest Stewardship, a private group that monitors forest holdings and products to ensure that wood marketed as environmentally friendly is produced with limited damage.

Studies have shown that 1) when timber is removed from a succession of narrow strips following the contours of the land, native trees grow back rapidly; 2) lightly logged forests have significantly fewer species than unlogged forests but some animals do better in forest that have been selectively logged because sun penetrating through the canopy allows plants that the eat to grow.

forest in Sumatra

Logging Primary Rainforests Unsustainable, Scientists Say

In 2011, scientists writing in the journal Biological Conservation argued that logging primary rainforests is not ecologically sustainable. Reviewing an extensive body of recent scientific literature, Philip Shearman of the University of Papua New Guinea and Australian National University, Jane Bryan of the University of Papua New Guinea and the University of Tasmania, and William F. Laurance of James Cook University concluded that current methods of harvesting tropical wood does not allow enough time for the trees and forest to recover. The researchers said this applies to conventional logging approaches as well as "sustainable forest management" techniques like reduced-impact logging (RIL), which aim to cut collateral damage to the forest from selective logging. [Source: Rhett Butler, mongabay.com, January 25, 2012; Shearman, P., et al. “Are we approaching ‘peak timber’ in the tropics?” Biological Conservation (2011), doi:10.1016/ j.biocon.2011.10.036]

"The recovery time taken for logged forest to resemble primary rainforest in biomass, timber volume and species diversity has been variously estimated at 45–100 years, 120 years, and 150–500 years," the scientists wrote. "Larger rainforest trees can range in age from many decades to a millennium or more, illustrating that recovery of large trees in logged forests requires far more than the nominal 30–35 year logging cycles commonly applied in the tropics."

Rhett Butler of mongabay.com wrote: “Shearman and colleagues says this inherent lack of sustainability motivates loggers to continually move into virgin forest areas to maintain timber production. Eventually loggers will find it harder and harder to find high value tropical forests to log, say the authors, pointing to several Asian countries — including Malaysia, Thailand, Laos, the Philippines, and the Solomon Islands — which have already seen their timber production peak.

“Shearman and colleagues use the Solomon Islands as a case study for the fate that can befall tropical countries that rely heavily on old-growth forest logging to produce raw-logs, which are "generally absent" from secondary forests. "For nearly a decade, the nation had been warned that the volume of timber annually harvested from native forests was too high and, if unchecked, that timber stocks would be seriously depleted by 2012," they write. "In 2009, the Central Bank of the Solomon Islands asserted that exhaustion of timber stocks had arrived even earlier than predicted and its economic consequences were likely to be severe."

“"Even in north Queensland, Australia, where advanced stand-yield models were eventually used to set annual timber quotas and the Queensland Forestry Department was heavily subsidized by government revenues, timber yields declined sharply from the 1960s to 1980s, as virgin or near-virgin forests were exhausted," they write. "If sustainable logging largely failed in north Queensland, what chance does it have in most developing nations, where economic pressures are paramount and a range of other complications, such as poor enforcement of environmental regulations, weak or non-existent land tenure, and often-high discount rates, further militate against sustainable forest management?"

Logging road in East Kalimantan, Indonesia

“The authors also highlight opportunities to directly tackle tropical forest logging, including bans on raw-log exports that have been adopted by many countries, reducing annual allowable cuts and extending rotation times, eliminating barriers to community ownership of forests through land tenure reform, cutting subsidies that favor industrial forestry, and establishing protected areas where logging is prohibited. Shearman, Bryan, and Laurance conclude that unless the logging industry undergoes fundamental changes, "logged tropical forests will continue to be overharvested and, far too frequently, cleared afterward, leading to an inevitable global decline in native timber supplies."

Image Source: Mongabay mongabay.com ; Wikimedia Commons

Text Sources: “The Private Life of Plants: A Natural History of Plant Behavior” by David Attenborough (Princeton University Press, 1997); National Geographic articles. Also the New York Times, Washington Post, Los Angeles Times, Smithsonian magazine, Natural History magazine, Discover magazine, Times of London, The New Yorker, Time, Newsweek, Reuters, AP, AFP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated November 2024