FAKE AND ALTERED DIAMONDS

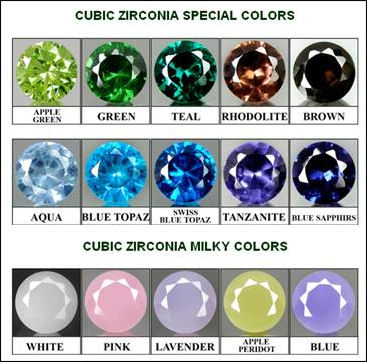

Zirconia special color Materials sometimes passed off as diamonds include synthetic white spinels and sapphires, zircon, strontium titanate, synthetic rutile and yttrium aluminum garnet (YAG). Most fake diamonds such as those made from cubic zirconia are easy for gemologists to spot.

A laboratory-grown crystal called moissanite looks so much like diamonds that even jewelers have been fooled. YAG, the stone featured in the Wellington jewel ads, is also very similar to a diamond. The easiest way to tell YAG from a real diamond is to immerse it in mineral oil. Because the chemical composition of YAG is almost the same as oil it facets seem to disappear in the oil while those of real diamond remain sharp and sparkling. Diamonds are used in cataract surgery on blades that cuts without tearing.

Buyers should be on the alert when buying a diamond. Sellers often try to sell customers diamond that have been altered or enhanced. Lasers are sometimes used to burn holes into diamonds to remove dark spots and inclusions which lessen a stone’s value. The holes are then filled with acid which bleached the imperfection and creates an illusion of flawlessness. Blemish and cracks can be masked by a type of molten glass that refracts light on the same way a diamond does. These alteration are often temporary and are easy to detect.

Colored diamonds are rare in nature. Irradiation and a combination of heat and pressure can transform a natural white diamond or a synthetic diamond into a colored diamond or change a brown diamond of low value into a valuable "colorless" stones. Trained gemologists can usually detect such alterations.

Websites and Resources on Gems: All About Gemstones allaboutgemstones.com ; Minerals and Gemstone Kingdom minerals.net ; International Gem Society gemsociety.org ; Wikipedia article Wikipedia ; Gemstones Guide gemstones-guide.com ; Gemological Institute of America gia.edu ; Mineralogy Database webmineral.com ;

Websites and Resources Diamonds: Info-Diamond info-diamond.com ; Diamond Facts diamondfacts.org/about/index ; Diamond glossary and FAQ heart-in-diamond.com ; Diamond Mining and Geology khulsey.com/jewelry/kh_jewelry_diamond_mining ; Diamond Mine mining-technology.com/projects/de_beers ; Costellos.com costellos.com.au/diamonds ; DeeBeers debeers.com/page/home/ ; Wikipedia article Wikipedia ; American Museum of natural History amnh.org/exhibitions/diamonds ;

Book: “The Heartless Stone: A Journey Through the World of Diamonds, Deceit and Desire” by Tom Zoellner.

Synthetic Diamonds

Zirconia CZ brilliant Synthetic diamonds are generally made by compressing graphite under pressure of one million pounds per square inch while the material is heated from 2500 degrees F to 3500 degrees F — roughly duplicated conditions deep in the earth that create natural diamonds. The process was invented by General Electric in 1954 and the diamonds produced are about a half a millimeter in size. Most synthetics show a distinctive patterns when viewed under ultraviolet light.

The first synthetic diamonds were made in the 1950s. were so tiny they were more like diamond dirt. Producing synthetic diamonds for cutting tools, optical equipment and lasers is now easy and common-place enough that there are thousands of small plants in China producing them. [Sources: Alice Park, Time, February 12, 2007, Urlich Boser, Smithsonian magazine, June 2008]

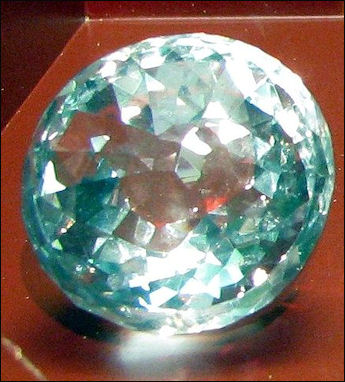

Producing gem-quality diamonds of a carat or larger is a far more difficulty endeavor. But the process has slowly improved over the years to a point where it is now possible to grow rough diamond stones than can be cut and polished into gems over a carat in size. As of 2008, the latest single-crystal diamond grown in a lab was 15 carats, or about 0.7 inches by 0.2 inches. A synthetic diamond placed in a high-pressure, high-temperature furnace at the Carnegie Institution’s Geophysical Lab that changed its atomic structure was so hard it broke a hardness gauge itself made from diamonds and endured pressures five million times greater than the atmospheric pressure at sea level.

DeBeers sells two machines that can distinguish between natural diamonds and synthetic ones. The machines detect chemical and structural characteristics that sometimes vary between natural diamonds and synthetic ones, but neither machine can tell the difference all time. The best way to determine whether a diamond is natural or synthetic is to cool it with liquid nitrogen and then shoot a laser through it to see how light behaves when it passes through it, the process is expensive and takes several hours.

Estimated World Production of Synthetic Diamonds, By Country (Thousand carats): 1) United States 258,000; 2) Russian Federation 80,000; 3) South Africa 60,000; 4) Ireland 60,000; 5) Japan 34,000; 6) Belarus 25,000; 7) Sweden 20,000; 8) China 18,000; 9) Ukraine 8,000; 10) France 3,000. [Source: United States Geological Survey (USGS) Minerals Resources Program]

Synthetic Diamond Production

Two processes exist to create authentic diamonds within a controlled laboratory setting for commercial production: 1) CVD (chemical vapor deposition) and 2) HPHT (high pressure, high temperature). The CVD method is like the concept of 3-D printing, and the HPHT method simulates the crushing forces found deep within the Earth that created mined diamonds. Diamonds are created by the HPHT method through the exposure of a sample of graphite, which is a form of carbon, to extreme heat over 2000o Celsius and extreme pressure, over 60,000 atmospheres. Laboratory HPHT equipment creates these conditions via a strong mechanical press and electrical current. [Source: Text sources: Forbes; Beyond the 4 Cs; Fortune]

Takashi Hagiwara wrote in the Yomiuri Shimbun: “Artificial diamonds are most commonly produced by decomposing methane gas in a microwave oven at temperatures of about 1,000 C. This process produces minute flakes of carbon, which pile up like accumulated snow to form a thin layer, or laminate, of diamond.” [Source:Takashi Hagiwara, Yomiuri Shimbun, October 17, 2010]

Apollo Diamond is leader in the synthetic diamond trade. Based in a secret location in a Boston suburb, it has made such advances that its executives fear for their own safety. The company is run by a father and son team: Robert and Bryant Linares. Robert began his career in crystal synthesis research at Bell Labs and later started a semiconductor company that he sold too get money to bankroll his dream of creating synthetic diamonds. Through trial and error, using equipment set up in his garage, he worked out the precise combination of gases and heat to grow large crystal diamonds.

Even DeBeers has entered the synthetic diamond business, with a division called Element Six, which has produced diamond wafers up to six inches across.

Making Synthetic Diamonds

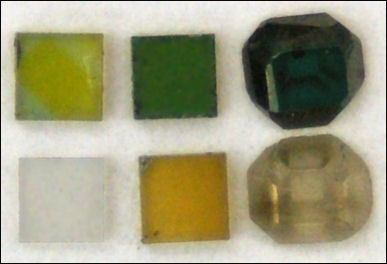

Irrdiamond specimens Apollo, Element Six and most other diamond makers rely on a process called chemical vapor deposition (CVD) to make synthetic diamonds. The process utilized high temperatures (1,800 degrees F) but relatively low pressures in a vacuum chamber to heat a plasma that crystalizes atom by atom into seed which grows a large single-crystal diamond over the course of a few weeks.

Under the CVD method: 1) methane and hydrogen gas are channeled through a chamber containing diamond seed slivers, 2) heat is applied, and a complex chemical reaction causes the methane to slough off its hydrogen atoms; 3) the remaining carbon deposits itself atom by atom as diamond onto the diamond-seed slivers.

Apollo uses washing-machine-size reactors covered with tubes and gauges to makes its synthetic diamonds. The seeds take two to four weeks to grow. Describing the diamond-growing area of the Apollo Diamond laboratory Alice Park wrote in Time, “Peer through a window of one of Apollo Diamond’s canister-like reactors...The inside of the cramped chamber is bathed in a magenta glow...Evenly arrayed on a small platter at the center of this colorful haze are what look like 16 lozenges burning with an even deeper pink hue...each of these small pinkish disks is a diamond, growing from a tiny seed crystal.”

Other companies make diamonds using the High Pressure, High Temperatures (HPHT) method, the tried-and-true method which was used to make the first synthetic diamonds. HPHT mimics the diamond-making process in the middle of the earth with heat of about 2,000 degrees F and pressure many of times greater than that on the surface of the Earth generated in a washing-machine-size device. Relatively large amounts of nitrogen are used, which turns the diamonds an amber color. Stones larger than six carats are hard to make using this method. The one advantage HPHT has over CVD is cost. It is much cheaper than even natural stones, A Florida-based company called Gemesis sells one carat synthetic amber diamonds for about $6,000, compared to $20,000 for the same size natural amber diamond.

“Cultured” Lab-Made Diamond Production

Diamonds grown using the CVD method are exposed to much lower pressures than the HPHT method within a vacuum chamber. A tiny piece of “diamond seed” or pure carbon is placed into the machine where tiny layers are built up, atom by atom, from a carbon plasma cloud. Regardless which process is used to create the authentic lab-grown diamond, once it’s reached the desired size, it is sent off to the same professionals who cut and polish mined diamonds. When grading a diamond and examining the four “Cs” (cut, carat, color, clarity), the term cut does not reference the shape of the diamond (i.e. oval, pear, heart, etc.) Rather, how a diamond is “cut” concerns the symmetry, polish, proportions, and other such components. How the diamond is cut will directly impact how “sparkly” it appears. [Source: Text sources: Forbes; Beyond the 4 Cs; Fortune]

The cut of a diamond is so important that people are willing to pay a higher price for a smaller diamond that is well-cut than a larger diamond with a poor cut. However, the price a diamond reflects its weight in carats. As such, cut is often compromised to preserve as much weight as possible. It’s for this exact reason many diamonds on the market are cut to poor proportions and why so many diamonds are available at the exact measurement, such as one carat or two carats as opposed to 0.78 or 0.89, for instance.

When a diamond is cut to a customer’s specifications, a loss of up to 75 percent of the weight of the rough stone can result. Therefore, two goals are present when a cutter is fashioning a diamond: 1) To preserve as much carat weight from the original stone as possible; 2) To achieve a striking and beautiful “optimal” cut that showcases the qualities of the stone.

The creation of diamonds in a controlled laboratory setting allows for unique customization and capabilities not available with mined diamonds. Consumers can specify the color, size, cut, and shape of the diamond. Most cultured-diamonds are hand-cut and hand-polished according to the most stringent industry standards set by the renowned gemological institutes. Because they tend to be harder than mined diamonds, synthetics can be more difficult to cut and require skilled craftsmen with extensive experience in the industry.

Lab-Made Diamond Industry: Market and Production Overview

Great Mogul Diamond copy Laboratory-grown diamonds are shaking up the diamond marketplace because they are identical in terms of physical, optical, and chemical properties to mined diamonds. While the industrial sector has embraced this new technology, the everyday consumer is still a bit skeptical. Learn how man-made diamonds are produced and graded in addition to trends in the synthetic diamond market.Synthetic Diamond Market When created in the laboratory setting, diamonds reach completion in as little as two to three months as opposed to the thousands of years it takes them to form underground. [Source: Time; Gemstone Institution of America (GIA); Luxury Research Journal; Bain and Company; Statistica]

Because these man-made diamonds form under controlled conditions that resemble the same growing environment deep within the Earth, they feature the same crystalline structure and chemical composition. Worldwide, the number of producers of authentic cultured diamonds is quite low with less than 50 internationally recognized labs. The top three leading countries in lab diamond production are: 1) China, 2) United States and 3) Russia.

Creating diamonds in the laboratory setting is not a new concept. In fact, the technology has been around since the mid-1950s. The industrial market has already adopted the use of synthetic diamonds for laser-cutting and polishing tools. Analysts estimate that over 95 percent of all industrial diamonds are now synthetic. In fact, synthetic diamonds outperform mined diamonds in terms of electron mobility and hardness which makes them superior for the industrial setting. Consumers decide the value a product holds to them. This perceived value influences buying trends. Research shows when consumers determine a worth of a product, three specific dimensions of value factor into the overall perception:1) Social — how valuable others perceive the product; 2) Personal — whether the product satisfies the individuals wants and desires; 3) Functional — how useful a product is.

In terms of man-made diamonds compared to mined diamonds, the industrial market embraced the new alternative because of the functional value offered by cultured diamonds, in addition to the fact these diamonds are more affordable. For the typical diamond consumer, especially those shopping for a diamond for an engagement ring, the other value factors such as social and personal, play a heavier influence on the final decision. Marketing tactics by the diamond industry have associated the price paid for a diamond as a direct reflection of how much the one that buys the diamond loves the one they give it to. Cultured-diamond sales are climbing on an annual basis. However, the marketing tactics against lab-made diamonds by the biggest mined-diamond companies are fierce. Promotional campaigns to smear the name of synthetic diamonds exist. It may take time before a surge in the popularity of cultured diamonds for luxury consumers explodes.

Cultured (Synthetic) Diamond Grading Reports

Great Star of Africa copy Today’s lab-grown diamond market has achieved substantial growth and there are many gemological labs that grade these diamonds according to the four Cs, including:

The Gemological Institute of America (GIA) which provides their GIA Diamond Grading Report. This non-profit organization offers grading reports for: 1) Diamonds, 2) Synthetic diamonds, 3) Colored diamonds, 4) Colored stones, 5) Pearls. [Source: Gemological Institute of America (GIA); American Gem Society (AGS); International Gemological Institute (IGI)European Gemological Laboratory (EGL)]

The American Gem Society (AGS) was the first organization that was grading gems using their own reports. This organization provides diamond and gemstone grading reports. Their website features a wealth of information, including but not limited to: 1) Guides on buying and selling jewelry; 2) Information about the history of diamonds; 3) Diamond trade information; 4) How to verify a diamond grading report.

The International Gemological Institute (IGI) is an organization used more frequently in Europe and Asia. Reports this IGI contain much of the same information from the GIA reports, except for proportions diagrams. When determining cut, the IGI report considers the following criteria:1) Total depth, 2) Girdle, 3) Pavilion depth, 4) Table width, 5) Crown angle.

The European Gemological Laboratory (EGL) is an organization that’s known for its lax standards in terms of diamond grading. Industry experts warn that a diamond’s clarity and color are typically two to three grades lower than the assigned grade from the EGL report. The EGL website provides resources such as: 1) Links to consumer education tools; 2) Retailer website tools; 3) Industry news and research; 4) Consumer reports.

Synthetic Diamond Jewelry

Apollo is already producing CVD diamonds for the jewelry market. In 2006 it started selling rough gems to a Boston jewelry retailer. A company called Staur sells a necklace made with two-carat synthetic diamonds for $129. The company claims the diamonds are the same quality and size of those on a $20,000 necklace made with natural diamonds.

Synthetic diamonds can be produced in a variety of colors, shapes and sizes. As of 2008, Apollo’s large colorless diamonds sold for around the same price a natural diamonds the same size. It’s pink, blue, champagne, mocha and brown diamonds go for about 15 percent less than natural stones of the same color, which are rarer and more expensive than white diamonds.

In 2007, the Gemological Institute of America, a leading grader of diamonds, agreed to rate synthetic diamonds using the same four C’s — carat, cut, color and clarity — as it does with natural diamonds. One jeweler who examined a synthetic stone produced by Apollo told Smithsonian magazine, “There’s no way to tell that it’s lab created.”

No one wants synthetic diamonds to be marketed too cheap, causing the diamond industry to collapse. On competition from synthetic diamonds, a spokesman for DeBeers told Smithsonian magazine, “Diamonds are rare and special things with an inherent value that does not exist in factory-made synthetics. When people want to celebrate a unique relationships they want a unique diamond, not a three-day-old factory-made stone.” Some synthetic diamond producers was to call their products “cultured diamonds.” The Jewelers Vigilance Committee (JVC), a trade group, is lobbying hard to prevent use of that term. “Cultured” is a term used in the pearl business.

Applications of Synthetic Diamonds

Lesser Star of Africa copy Diamonds have a number of unique qualities that makers them ideal materials for much more than just jewelry and cutting tools. Because they conduct heat so well they hold great promise for advancing the electronics industry and are especially useful making a new generation of processors that don’t generate large amounts of heat like silicon ones do. This application alone paves the way for super-thin laptops, wristwatch-size cell phones and digital recording devises that hold thousands of movies in a palm-size device. Another advantage that diamonds have over silicon is that they are stronger and don’t break down at high heats. Silicon is currently the primary material used to make processors and semiconductor.

Diamond’s ability to dissipate heat also has applications for things like sophisticated lasers and the windows of spacecraft, protecting them during launching and returning into the atmosphere. The U.S. Navy is studying the use of diamonds in next-generation grid switches, as a wear-resistant coating for military equipments and as a material to use in biological weapon detectors.

Biologists are attracted by diamond’s inertness — the fact that it doesn’t react with any substance and doesn’t degrade even when doused in powerful natural acids and other chemicals found in the body. One application being studied is a diamond-based electrode that could be designed to react chemically to certain proteins.

Apollo grows CVD diamond wafers that are large enough and of a quality that makes them useful in the electronics industry. CVD produces uniform, consistent diamonds that, for example, can be used as effective transistors and semiconductors. Apollo’s president Bryant Linares told Time , “You need to make other seeds that will allow you to control the end product. For semiconductor manufacturing, that means an extremely smooth and flat surface. For the first time we’ve done that.” Apollo is currently working on high-quality diamond slivers that can be marketed comedically. The main drawback with diamond semiconductors — one that will take some time to overcome — is the high cost of producing them.

Diamond Semiconductors

Takashi Hagiwara wrote in the Yomiuri Shimbun: “The artificial diamond super semiconductor is being developed by the Diamond Research Laboratory of the National Institute of Advanced Industrial Science and Technology (AIST). The AIST team has found a way to accelerate the diamond laminating process, and can efficiently produce diamond laminates measuring 2.3 centimeters square and 0.4 millimeter thick — a size that ranks alongside the largest artificial diamonds produced. [Source: Takashi Hagiwara, Yomiuri Shimbun, October 17, 2010]

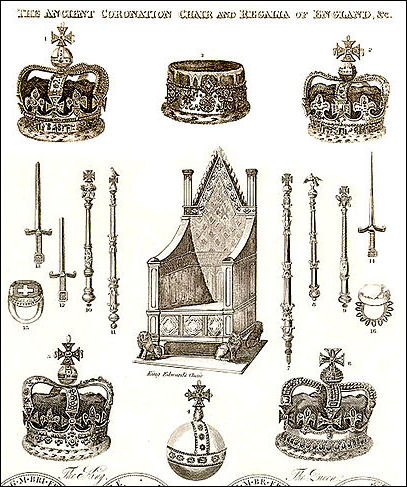

Will they one day make these

(the British Crown Jewels) with synthetic gems?

“While diamond has natural insulating qualities, adding minute amounts of boric acid and some other substances during the methane-decomposition process produces diamond that also acts as an excellent semiconductor. The resulting substance is described by the AIST team as "the ultimate insulator," far excelling silicon in terms of thermal radiation and voltage resistance. "Given that artificial diamonds can be produced from carbon, which is obtainable in abundance, the diamond semiconductors we envision would be well suited to mass production," said Shinichi Shikata, 56, who heads the AIST team. He joined AIST after quitting a managerial post with a diamond-processing company six years ago. Shikata and his team foresee diamond semiconductors being used in electric vehicles and gas-electric hybrids.

“Silicon semiconductors require a cooling system to prevent malfunction due to overheating. This is not true of diamond semiconductors, Shikata said, because of diamond's heat-transferal efficiency. The AIST team last year created a prototype semiconductor element measuring 1.6 centimeters square, incorporating a 3 square-millimeter diamond semiconductor. If about 10 such elements were combined to form one large element, it would be suitable for use in the power control system of a hybrid vehicle, Shikata said.

“A hybrid car equipped with such technology would consume about 960 kilowatt hours less per year than a conventional hybrid. If every hybrid vehicle currently in use worldwide had such a system in place, their collective carbon dioxide emissions would be reduced by about 5 million tons over 40 years, he said. "Our goal is for diamond elements to be in practical use within 10 to 15 years," he said. "If mass-produced, their production cost would be comparable to that of silicon-based elements." "We'd like to see diamond semiconductors become commonplace some day, since they would be sure to help realize a low-carbon society," he said.

“Shikata's laboratory also has been pursuing research into developing high-performance transistors with artificial diamonds. By manipulating the elemental composition of the carbon flakes, the resulting artificial diamond's heat conductivity can be increased by 150 percent, and have the ability to latch on to electrons, Shikata said. "We can apply this phenomenon to the production of a high-performance transistor," he said.

Image Sources: Wikimedia Commons

Text Sources: New York Times, Washington Post, Los Angeles Times, Times of London, The Guardian, National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, AFP, Wall Street Journal, The Atlantic Monthly, The Economist, Global Viewpoint (Christian Science Monitor), Foreign Policy, Wikipedia, BBC, CNN, NBC News, Fox News and various books and other publications.

Last updated May 2018