TOY INDUSTRY IN CHINA

Workers at a Disney factory China makes 80 percent of the toys sold worldwide. Most are made in Guangdong Province, where $12 billion worth of toys are produced every year and 1.5 million workers are employed in more than 6,000 toy factories.

Among the Chinese-made toys found on the shelves of Toys-R-Us are Mickey Mouse Clock Shops ($29.77), Mickey Mouse Marching Bands ($29.77), hand-painted Christmas rocking horses ($9.77), musical snow globes ($14.99), Santa "touch" lamps ($9.88), Santa's elves music boxes ($9.77), 14-piece hand-painted nativity scenes ($22.99), smash-faced dolls ($26.99), Western Stampin' Barbi dolls ($13.99) and Emmet Kelly Circus Trains ($69.99). About the only thing not made in China are the Chinese Checkers ($19.95) which bear a "Made in the U.S.A." sticker. [Source: TJ Edwards, Washington Post]

There around 8,000 companies in China that manufactures toys and they are under strong competitive pressures Some of the factories have been accused of having poor working conditions, paying workers below the minimum wage of 33 cents an hour, requiring workers to put in long hors and not providing adequate benefits. Only 35 cents from an exported toy retailing for $20 remains in China.

Factories in Shenzhen, Guangzhou and the Pearl River Delta produce many toys, including Barbies, Ninja Turtles, Mickey Mouses, Cabbage Patch dolls, Might Morphin Power Rangers, and Tickle Me Elmo.

Guanyo, a town that is a two hour drive north of Guangzhou, is regarded as the world’s biggest toy manufacturing center. A Mattel factory that makes Hot Wheel cars and other toys covers 300,00 square feet, operates 20 hours a a day and has 3,000 employees working there. Most of the workers are females, who work 10 hours a day, six days a week.

Daoingguan, a city near Shenzhen and Hong Kong, is another candidate for the toy capital of the world Its 4,000 factories are said to produce about half of the toys produced in China. More than 500 toy manufacturers are added every year. Many of the buyers are from overseas.

In November 2007, the American toymaker Tomy, which makes 90 percent of its toys in China, announced it cut production in China by a third because of surging labor costs and move production to other Asian countries, most likely Thailand and Vietnam.

By one estimate 20 percent of Chinese-made toys and baby cloths are below the standards reported by China’s consumer watchdog. Industrial waste has been founds jammed inside some toys.

Websites and Sources: China Labor Watch chinalaborwatch.org ; China Labor Bulletin clb.org.hk/en ; China Law Blog on New Labor Laws chinalawblog.com ; Book: Understanding Labor and Employment Law in China (Cambridge University Press, 2009) cambridge.org/us ; Gloomy Photos of Workers zhouhai.com

Articles About LABOR IN CHINA factsanddetails.com MIGRANT WORKERS IN CHINAFactsanddetails.com/China ; INDUSTRIES IN CHINA factsanddetails.com

Toy Industry Troubles in China

The toy industry was hard hit by the economic crisis in 2008 and 2009 Half of China’s toy exporters, which exported nearly $8 billion worth of goods in 2007, went out of business in the first seven months of 2008.

According to Xinhua, 3,631 toy exporters — 52.7 percent of the industry’s enterprises — went out of business in 2008 because of higher production costs, wage increases for workers and the rising value of the yuan. Smart Union Group, which has three large factories, closed down, leaving 8,700 workers without jobs. After workers protested in the streets the government promised to pay them $4 million in back wages and help them find new jobs.

In November 2008, hundreds of workers laid off from the Kai Da toy company rioted in Dongguan, Guangdong Province over a dispute about severance pay. They protesters clashed with police and attacked the offices of a toy factory executive. The Guangzhou Daily reported: Rioters “smashed one police vehicle and four police patrol cars...fought with security guards...and entered factory offices, broke windows and destroying equipment.”

A 36-year-old machinist told the Los Angeles Times, “We saw the police beating five workers with sticks, several of them unconscious...Then many workers rushed out and surrounded them, Later there were thousands of people there. They smashed police cars, doors and computers.” After the protests workers received about $900 in severance pay.

Making Barbies and Cabbage Patch Dolls in China

Barbies are made by Mattel-owned factories in China, Malaysia and Indonesia. They conditions at their factories are generally better than the conditions at factories run subcontractors that makes toys and dolls for other companies. The "Made in China" is a bit misleading. One businessman told the Los Angles Times, "In most cases, the only things that China supplies are the factory space, labor and electricity."

Even though Barbie dolls have a "Made in China" label attached to them only 35 cents of the doll's retail price of $9.99 ends up in China, most of it wages to 11,000 young peasant girls working at two factors in Guangdong that operate plastic mold injection machines, sew clothing and paint features on the dolls. A typical doll passes through 15 separate paint stations. The only raw material used in making the Barbies are the cotton for some of the clothes. The plastic comes from Taiwan, the oil to make the plastic comes from the Persian Gulf, and the machines to make the dolls are from Japan.

Cabbage patch dolls, Winnie the Pooh, Mickey Mouse and Goofy dolls are made by the 2,800 mostly female workers at the Cha Shan Garment and Toys Factory. Workers there earn about $80 a month, with $10 of that deducted for dormitory beds and meals. The Qulaidux Industrial Companies has produced 80 million Stars war characters, 30 million Mighty Morphin Power Rangers and 10 million Cabbage Patch dolls. It has annual sales of $100 million. The workers have an average salary of $80 a month.

A worker at in the Daojiong Hequi Plastic Processing factory in Dinggian earns $50 a month putting in 14-hour days slicing off artificial hair for dolls.

Workers at Chinese Toy Factories

Chinese-made bobbing head dolls

Toy production is in cycles and seasonal and often ends with massive layoffs. The work is hard, dangerous, noisy and exhausting

By one count over 1 million workers produce 50,000 models of toys in the Shenzen area alone. Most are low-paid migrant women in their late teens or early twenties The largest factories employ 15,000 workers, who work. live and sleep at the factories and go home only once a year.

Kin Ki Industrial is China’s leading toy maker. It makers the Etch-a-Sketch and other famous toys. On paper it claims its workers are paid a decent wage, live in comfortable surroundings and rarely work on weekends and late at night. In reality most of the teenage migrant workers that work there put in long hours and live in cramped dormitories.

My one estimate a China workers would need to work six months to earn the equivalent of the cost of a Thomas the Tank engine train set.

See Female Workers at a Barbie Factory, Labor

Poor Working Conditions at Chinese Toy Manufacturers

Gethin Chamberlain wrote in the The Guardian, “Big brands such as Disney, Lego and Marks & Spencer pay only a fraction of the shop price of products to the factories that make their toys. Last summer — as factories geared up to cope with demand for the Christmas period — investigators spent three weeks in the industrial cities of Shenzhen and Dongguan. In some cases, they found that employees: worked up to 140 hours overtime a month; - were paid up to a month late; - claimed they were expected to work with dangerous tools and machines without training or safety measures; - had to work in silence and were fined up to £5 for going to the toilet without permission. [Source: Gethin Chamberlain, The Guardian, December 3, 2011]

The human rights group Students & Scholars Against Corporate Misbehaviour (Sacom) accuses big global brands of failing to pay the factories enough, with workers suffering because factories undercut one another in an attempt to secure contracts. The report also criticises the industry's own regulator for failing to clamp down on rights abuses.

Spokeswoman Debby Chan Sze Wan said: "In the run-up to Christmas, toys are a popular choice as presents for children. They probably bring joy to consumers and the toy companies, but the workers cannot afford toys or books for their beloved children. "The hardship of workers is due to the exploitation in the global supply chain. If the brands do not raise the unit price and change their purchasing practices, no structural change in working conditions in the toy industry is feasible."

Gethin Chamberlain wrote in the The Guardian: Perhaps the most insidious effect of the long hours and poor wages was how it tore families apart, separating mothers and fathers from their children for all but a few days a year. Many workers were too afraid to speak to the investigators from Sacom but two women did agree to talk on condition that their names were changed. [Source: Gethin Chamberlain, The Guardian, December 3, 2011]

Wang Fengping, 27, has two daughters, seven and five. They live a 10-hour train journey away from the On Tai Toys factory. She and her husband earn £200 a month making toys for Disney and others, but cannot afford to bring the children to the city. Instead, the girls are cared for by their grandparents. Wang calls them two or three times a week. The younger one always asks her when she is coming home. "Very soon," Wang always replies.

The reality is that they will meet only once a year, at Chinese new year. She keeps her spirits up by telling her workmates stories of how well the girls are doing at school. Sometimes she sings them songs the girls have learned at school and then sung to her down the phone. "Our family will not die from hunger, but cannot be fed with this wage level," she said.

Ma Hui, 25, works for the Hung Hing Printing Group, making items for M&S, Lego and Disney. She has a two-year-old daughter, whom she had to leave behind when the child was just three months old in the hope that she could earn enough to one day return home to set up her own business and reunite the family. She, too, only sees her child once a year and has hung a picture of her daughter on the dormitory wall next to her bed.

Poor Working Conditions at On Tai Toys and Hung Hing Factories

Gethin Chamberlain wrote in the The Guardian: Investigators targeted three factories, including On Tai Toys Company, which manufactures for Disney and a number of other international brands, and Hung Hing. All the factories are certified as decent toy manufacturers by the International Council of Toy Industries, which is supposed to police ethical standards in more than 2,400 factories that employ an estimated 1.7 million people worldwide. But Sacom has accused ICTI of permitting "rampant labour rights violations" in factories it has certified. [Source: Gethin Chamberlain, The Guardian, December 3, 2011]

At the Hung Hing factory the researcher found that the 8,000 workers put in up to 100 hours of overtime a month, far in excess of the legal maximum. Workers say they have to sign a document agreeing to work additional overtime on top of the legal maximum. The basic wage was £132 a month (up to £250 with maximum overtime payments) but wages were paid up to three weeks late.

Workers complained of inadequate training with the factory machines and last year one worker died when he fell into a machine. They said there were frequent injuries and concerns over the chemicals used. There were also complaints about the standard of the dormitories, where water for washing and flushing toilets is turned off at 10pm.

At the On Tai Toy Company the researcher found that most of the 1,500 workers were aged between 30 and 50, though around 300 students are drafted in to help cope with the peak season.The researcher spent three weeks in the factory and found workers put in up to 140 hours of overtime every month, nearly four times the 36 hours a month legal limit. Basic pay is £110 a month, but wages were paid a month late, in breach of labour law. During the peak summer season workers could make up to £240 a month, including overtime, but that falls to £140 during low season.

A typical working day during the peak season starts at 8am and does not end until 10pm. Workers routinely put in six-day weeks, but if the factory is busy there are no days off. Workers complained that they were banned from talking to one another on the production line and were fined up to £5 if they went to the toilet without applying for an "off-duty" permit. They reported regular burns from soldering irons and electric shocks from old hair dryers used to set glue, along with concerns about the effect on their health of unmarked chemicals they have to work with. The law requires the chemicals to be identified and for workers to be instructed in what to do in case of an accident. Up to 10 workers share each 20 square metres dormitory room, which is fitted with bunk beds. Dozens share the toilet and the outside of the building is piled deep with rubbish, which is home to rats.

Disney and Lego Respond to Charges of Poor Working Conditions

Gethin Chamberlain wrote in the The Guardian: In response to the Sacam researchers' allegations, Disney said: "The Walt Disney Company and its affiliates take claims of unfair labour practices very seriously, and investigate any such allegations thoroughly." Lego said the investigation into working practices at the factory had raised very serious issues, which it took very seriously and which it had asked its licensing partner, Dorling Kindersley, to investigate. [Source: Gethin Chamberlain, The Guardian, December 3, 2011]

"Ensuring respect for workers' rights is very important to the Lego Group and all our partners agree to adhere to a strict set of guidelines — our code of conduct. The Lego Group requires all of its licensing partners to give a written assurance that their vendors, too, comply with the Lego Group's code of conduct, and to audit their suppliers on an annual basis. Adhering to the code of conduct is something that we prioritise in our engagement with our partners. It appears that in this case the code may have been broken and we are addressing this urgently. Once we have the full facts we will take decisive action."

Dorling Kindersley said that it was deeply concerned by the allegations and had contacted Hung Hing to express its view: "We have strict ethical sourcing standards covering all the issues identified by this investigation. The allegations, if true, would demonstrate a breach of these standards." It said the factory had recently been audited, but that would now be reviewed, adding: "Our terms of business are absolutely clear, that any supplier in breach of our ethical standards is required to change their practices or face termination."

A spokesman for Marks & Spencer said: "We are a very small customer of the Hung Hing Printing Group — less than 0.5 percent of its business. We take any allegation that suggests a breach of our strict ethical standards very seriously and work closely with all our suppliers, including this factory, to ensure they adhere to our strict standards."

Hung Hing responded with a four- page letter from general manager Dennis Wong in which it admitted that workers could be asked to do overtime of up to 92 hours a month in July and August. The letter said that last month overtime ranged between 23 and 77 hours. The company said workers who refused to do the extra hours were not penalised. It blamed late payment of wages on the complexity of calculating the rates for more than 8,000 workers, and argued this was a standard industry practice. It insisted that workers did receive safety training, but warned that individual managers would be held responsible for future lapses and would have pay deducted. The company said that providing water to the toilets after 10pm was wasteful and that barrels of water were available for workers to use to flush.

Mattel in China

Mattel, the world’s largest toy maker with about $3 billion in total sales, produces about 65 percent of its toys in China It owns and operates 13 factories in China and does business with 20 to 30 others, , who turn ferry out some of the work to subcontractors. It has 60,000 to 80,000 workers in China, many more if workers for subcontractors are factored, in.

In the 1990s Mattel was criticized for running sweat shops but these days it is largely regarded as a model for how companies should operate in China. It pays workers relatively well and give them good working and living condition in the plants it owns in China and require the same of its contractors.

In 1997, after NBC Dateline ran a piece that accused Mattel of using underage workers at a Barbie plant in Indonesia and forcing them to work long hours — charges that Mattel has said were mostly unfounded. After Dateline piece Mattel decided to take measures to improve its image. One thing it did was hire Prakesh Sethi, a professor at Baruch College in New York who has made of career of trying to improve working conditions for low-paid workers. Sethi is in charge of monitoring working conditions at Mattel factories in China.Mattel allowed him to make sneak visits to Mattel factories and post his findings publically and uncensored.

Some have said that Mattel has gone further than practically any other company doing business in China to be a good corporate citizen, It has opened itself up to unparalleled scrutiny and done a lot to improve salaries and working conditions. Under Sethi’s guidance, Mattel conducts a number of rigorous, sometimes unannounced, inspections and its factories have done things like install eyewash stations and safety showers where dangerous materials are used. It also requires workers to wear glasses and steel-tipped shoes, improved the conditions at dormitories and increased salaries.

Mattel has begun looking to China as a new market. As of 2009, China accounted for a small percentage of Mattel’s total sales but growth was in the double digits. In March 2009, as part of the celebration to mark Barbie’s 50th birthday, Mattel opened a six-story, pink Barbie “everything girls” flagship store in Shanghai complete with a spa, café, design studio, fashion stage and every Barbie-branded product available on the market. The store is aimed not only at girls but also younger and older women. Barbie was introduced at the New York Toy Fair in March 1959, Since then more than 1 billion Barbies have been sold, with many of the ones made in the 1990s and 2000s produced in China.

Wal Mart factory

Mattel Workers in China

Workers at factories with contracts with Mattel sometimes work 24-hour shifts at 20 cents an hour, are are denied bathroom breaks and fear being beaten if they complain. At Mattel-owned factories management is required to follow a 112-item code of conduct and the company is widely recognized for offering good working conditions and health care and other benefits. The factories have comfortable accommodation, computer centers that offer classes, and a health club. Workers on the assembly line change stations to avoid repetitive motion injuries. Mattel is concerned about its image and doesn’t want to linked with sweat shops.

A typical worker at Mattel is a woman in her 20s who earns $175 a month for a 60 hour week and lives in a company dormitory and eats in a company cafeteria, with expense deducted from her salary. Workers generally work no more than two or three years and return home with their savings. The annual turnover rate is a s high as 200 percent.

Disney in China

Worldwide Disney has agreements with 6,000 licensees that make their own production contract with factories. Although Disney conducts occasional spot checks and keeps record on factories that make its stuff it relies on the licensees to follow the ruler and tell the truth about what they are doing. But sometimes they don’t and Disney doesn’t know about it.

1) Disney dolls are licensed to Thinkway Toys in Markam, Ontario; 2) Markham has the dolls manufactured by workers earning $2 a day for subcontractors in southern China; 3) they are then shipped to Hong Kong and inspected by buyers from American retail chains like Wal-Mart and Toys "R" Us; 4) then shipped from Hong Kong to Long Beach and forwarded to retail distribution center; 6) and finally arrive at local stores, where they sell for around $8.00.

Labor groups have criticized Disney for it arm’s length relationship with manufacturers. Not only does the system invite deception it provides Disney with a ready excuse if something unsavory is disclosed. Unlike Nike, Disney does not maintain long-term relationships with its factories and won’t identify factories that produce its products. Still Disney is a $35.5-billion corporation that thrives on trust and public good will and is not deaf to its critics. One Disney executive told the Los Angeles Times, “The tremendous growth of our business over the last several years requires us to further increase our efforts to improve the well-belong of factory workers.”

Disney Workers in China

Disney has been criticized for the poor labor conditions at some of the factories that produce its merchandise. Attention was brought to the issue after workers who put in 15-hour days at a factory that produced Mickey Mouse, Donald Duck and Snow White statuettes sued their employers for back pay and compensation and won. The workers were often only given one day off a month, and were not given any overtime. Disney claimed the problem was not their fault, but was the problem of the company that Disney licensed to produce the statues.

Factories that produce Disney products have been charged with employing forced overtime, mandatory seven-day workweeks, paying salaries as low as 16 ½ cents an hour, housing workers in cramped, fetid dormitories and imposing steep fines for minor infractions such as showing up five minutes late for work. There have also been reports of beatings and verbal abuse and workers vomiting at their work station from breathing in chemical and paint fumes in poorly ventilated faculties

Describing a worker who get paid $65 a months for a 55-hour work week, assembling a Disney Mini Touch “n Crawl Minnie dolls, Abigail Goldman wrote in the Los Angeles Times: “Li moves with lightning speed — glueing the pink bottom, screwing it into place, getting the rest of the casting to adhere, tamping it down with a special hammer. Pulling the battery cover through its slats, soldering where she glues, testing to make sure the leg joints on the side still work, then sending it down the line...The entire process takes 21 seconds.”

Firework display in Hong Kong

Mattel Toy Recall

In the summer of 2007 the American toy maker Mattel issues three recalls, involving millions of toys produced in China. The recalls came shortly after 1.5 million Chinese-made Thomas and Friends trains produced by toymaker RC2 and hundred of thousands of Chinese-made vinyl bibs, sold by Toys R Us and marketed under the Koala Baby, Especially for Baby and Disney baby labels, were recalled because of the presence of lead.

In early August, Mattel recalled 1.5 million Fischer Price toys because they contained lead paint. A total of 83 products were involved, including characters such as Diego, Dora the Explorer, Big Bird and Elmo. Lead can cause a variety of health problems, including nerve and brain damage, and is especially dangerous to children. The problem was linked to Lee Der Industrial, a contract manufacturers that produced the toys. Mattel stopped using Lee Der. The Chinese government revoked its license. The owner of the company, Zhang Shuhing, committed suicide by handing himself in a factory warehouse.

In mid August Mattel recalled 18.2 million toys worldwide, with around 9 million in the United States, mostly because of problems related to small magnets coming loose and presenting a choking hazard if swallowed. Some were recalled because of lead paint. It was the largest recall in Mattel history. A total of 63 different products, including 7.3 million Polly Pocket toys, 1 million Doggie Day Care toys, and Batman toys were recalled. In November 2006, Mattel recalled 2.3 million Polly Pockets toys with the same magnet problem. Magnets are especially dangerous if more than one are swallowed and they stick together inside the body, blocking or damaging internal organs.

Some 436,000 toys based in the animated Cars movie that contained lead were part of the 18.2 million toy recall. The problem was inked to a Chinese subcontractor Hing Li Da, hired by Mattel contractor Early Light Industrial, which had worked with Mattel for more tan 20 years. Both Hing Li Da and Lee Der and broke Mattel rules whichs requires them to buy paint from one of eight certified paint suppliers. Lee Der bought paint form an uncertified company. Hing Li Da used an uncertified paint. Analysts blamed the problems on rising labor and material costs and demands by American companies to keep prices low, forcing toy makers to cut corners and find ways to squeeze out profits. Mattel was blamed for being unaware of the extent of which its contractors gave out work to subcontractors.

The magnet problem it turns out was a design flaw that was the Mattel’s fault not the fault of the Chinese producers. In September 2007, Mattel sent a top executive — a vice president — to China to personally apologize to China’s product safety chief. “Mattel takes full responsibility for these recalls and apologizes personally to you, the Chinese people and all of customers who receive the toys,” the vice president said, Some analyst speculated that Mattel mad made move to head off being slapped with extra taxes and regulations by the Chinese government.

Mattel reported profits in 2008 despite the recalls.

More Toy Recalls

In September 2007 Mattel recalled 800,000 more Chinese-made toys — this time furniture for Barbie play sets. In October 2007, 500,000 Chinese-made key chains and kids products such as Winnie the Pooh bookmarks to Baby Einstein color blocks were recalled for containing excessive amounts of lead.

In November 2007, 4.2 million toys called Aqua Dots were recalled in the United States after a 2-year-old boy in Sydney Australia went into a shallow coma and suffered seizure-like spasms after ingesting Bindeez beads, which are essentially the same as Aqua Dots. After being swallowed the beads released a chemical similar to GHB, the banned date rape drug. In 2007 Bindeez had been named toy of the year in Australia.

By the time the Chinese government confirmed there was poison in the beads and found the factory in Shenzhen that produced them and toook away its license nine children had been sickened by the drug. Even so action taken by Beijing was seen as being particularly swift and decisive. The brightly-colored beads — which can be placed together and formed into a solid mosaic by pouring water on them — are sold in 40 countries under several names and a produced in China under contract to a Taiwanese toy maker. The source of the GHB was a cheap glue that cost a third less than the glue that was supposed to be used.

In March 2008, 2.4 million Chinese-made toys produced for Mega brands were recalled over concerns that magnets could be ingested. But like the Mattel magnet toy recalls the problem was more of a design problem than a Chinese production problem.

Fallout from the Mattel Recall

Wal-mart said that one of the biggest concerns among its shoppers was the safety of Chinese-made toys. Some of the toys that were recalled had 220 times the amount of lead allowed in U.S. toys. Toy companies that produce their toys in the United States and emphasize the quality of the products profited Toymakers that relied on Chinese producers were worried there might be a boycott of Chinese-made products but that didn’t happen.

Beijing responded by saying it would take steps to eliminate lead paint in toys and launched a campaign to ferret out unqualified toy makers and subcontractors and shut them down. A government watchdog agency announced, “An examination will be conducted across the country on licensed Chinese toy producers and exporters to clear out those unqualified ones...Export quality certificates will be revoked for those companies who found to have serious problems.”

Chinese toy makers were unfairly blamed for the Mattel magnet problem which was the fault of the Mattel designers not the Chinese manufacturers. In September 2007, Mattel apologized to China over the recall. In an effort to improve strained ties with the Chinese manufacturers that make most of its toys and are a source of much of the company’s profit, a top Mattel executive apologized directly to China’s product safety chief.. Analysts said there must have been heavy pressure on Mattel to apologize, possibly a threat of higher taxes and more regulations of they didn’t.

Mattel’s profits dropped 1 percent as a result of the recalls. The company has said in the future in will produce more toys in factories directly under the company’s control rather than give the work out to contractors. It fired a number of subcontractors and carefully scrutinized others; tightened rules on the use subcontractors by contractors; and said it wold make more of an effort to visit subcontractors. Mattel already has a huge test laboratory in Shenzhen, China where employers break toys, analyze their materials and preform another tests to make sure they are safer. Other toymakers said they too would scrutinize their suppliers, contractors and subcontractors.

In November 2007, the Chinese government announced that it had suspended export licenses of 750 toy companies because of of quality control problems. Another 690 had been ordered renovate or improve their facilities. Guangdong Province launched a new system that required toymakers to pass an inspection to receive “quality licensing” and operate legally.

Christmas Product Industry in China

Many of the products associated with Christmas are made in China: Christmas lights, stockings, wreaths, wrapping paper, toys, ornaments, plastic Christmas trees. Some are made labor camps and prisons.

About one out of every four artificial Christmas tree and Christmas ornaments sold in the United States is made in China. Many of them are produced in 3,000 or so factories in the Shenzen area that speacialize in these products. Most of them are Hong Kong or Taiwanese owned.

The export of Chinese-produced Christmas trees and ornaments grew from around $300 million in early 1990s to around $1 billion in the early 2000s. In 2000, the United States imported $78 million worth of Christmas trees, $535 million worth of ornaments, $211 million in Christmas lights from China.

The manufacturing cost a typical artificial tree is around $11. Two third of that cost is materials, mostly plastic and wire. Labor, electricity and water account for the other third.. The tree is sold to a buyer for $13. By the time it reaches Wall Mart or K-mart in the United States it sells for $125.

The Zhingyo Gifts Import & Export Co.,a Beijing subsidiary of a larger conglomerate, earns a $100 million a year from exporting Christmas-related goods, mostly to the United States and Europe.

Many Christmas ornaments, Santa hats and other Christmas items are now made in the Yiwu area in Zhejiang Province. Much of the stuff is made in workshops and small factories that lie on land not long ago occupied by rice paddies.

In 2006, the world’s largest container ship, “Emma Maersk“, was dubbed “the ship that brought Christmas” when is docked in southern England with 45,000 tons of Chinese-made toys, decorations, books and computers.

About 85 percent of the plastic Chinese trees sold in the United States come from China. At its peak the Boji Arts and Crafts Christmas tree factory in Shenzhen exported 1.6 million trees to the United States each year and employed 2,000 workers.

Christmas-related industries were hard hit by the economic crisis in 2008 and 2009. Growth was down nearly 40 percent from the previous year.

Workers in Chinese Christmas Products Factory

Workers at factories that make Christmas product typically make about $125 a month. Many of the workers have only a fuzzy idea of what Christmas is. Some had never even heard of it before they starting making Christmas stuff.

Describing one factory, Peter Goodman wrote in the Washington Post: “On the concrete floors...migrant workers...squat in front of hissing machinery as they melt chips into moldable plastic, pulling levers by hand to squeeze out Christmas tree ornaments. A woman sits barefoot by an empty packing tube, knife in hand, shaving extra bits of plastic from the finished products before depositing them in an oil drum.”

“Two dozen men feed spoons of green plastic into a machine that stretches it along a conveyor, creases it onto a wire, then slices both sides into fringes, yield branches for artificial Christmas trees. Other men fuse the branches together, jamming them with their bare hands intro the center of the spinning rotor.” A number of workers have lost their hands working at Christmas ornament factories.

Fireworks Industry in China

China is world's leading producer and exporter of fireworks. It makes both big fireworks used big time displays and small fireworks used in backyard parties. Most f the products have English labels and names like TNT Killer Bee, Whistling Cuckoo, Purple Rain, Cracker Bomb and Stick Torch.

China exports about $250 million worth of fireworks a year to dozens of countries. About 95 percent of the consumer fireworks sold in the United States are produced in China. It has been that way for the last 20 years.

Fireworks is a growing industry. The amount of fireworks used in the United States increased from 29 million pounds in 1978 to more than 152 million pounds in 2000. The retail fireworks market in the United States was worth $650 million in 2001, up from $425 million in 1998. Because Chinese fireworks are so cheap, retailers can mark up products 200 percent to 600 percent and still sell them for reasonable prices.

First Fireworks, See Chinese Firsts, History. Also See Recreation and Sports

How Fireworks Work

Fireworks are propelled into the sky more or less by the same chemicals used to make gunpowder: saltpeter, sulfur and charcoal. Most have the same basic parts: 1) the starting powder that catches fire: 2) the bursting powder that causes the final explosion; and 3) the quick match lead the spark of fire from one point to another. Resin, camphor, gum and similar substances control the strength of the explosion. Firecrackers explode with a loud bang because the explosives are housed in a tightly-closed cylinder.

The colors come from different chemicals, mostly bright-burning metallic salts: red comes from strontium nitrate, blue comes from chlorine-laced copper salt, deep yellow comes from sodium salts, green comes from barium, the electric white comes from magnesium and aluminum. Chlorine compounds are used to intensify the colors.

Big Fireworks

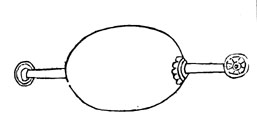

thunderbolt ball bomb

Most fireworks used in Forth of July displays are roman candles (fireworks that are propelled into the air by compressed gases). They operate under the same principles as missiles and large rockets and are propelled by rapid burning saltpeter-sulfur-charcoal mixture.

Fireworks used in Forth of July displays consist of roman candles hand "cakes" and "display shells," the largest of which look like brown-paper-wrapped bowling balls sitting on squat cardboard cylinders of black powders. The shells shoot 100 feet into the air for each inch of their diameter, with some reaching 1,200 feet before detonating.

Most display fireworks are shot from cylindrical tubes. Most are cylindrical in shape and are made by pressing a powder ball of a single color in a machine. Cylindrical shells explode out of one end of the shell. Round ones explode in all directions at once.

Small balls called stars burn after a shell burst in mid air, forming the “petals; of firework flowers. Stars that successively change color are made by covering small objects with concentric layers of colored powder.

The stars in roman candles are made by hollow balls made of an explosive mixture and metallic salts that give them color. "Gum and shellac hold the shape of the balls. These are evenly distributed in the tubes, and the spaces between them are filled with a slow-burning substance. Pinwheels are made by coiling long paper tubes, which are lightly filled with a fast-burning mixture."

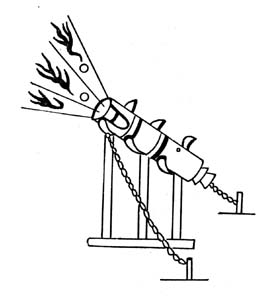

Firework Production in China

Ancient flying cloud fireworks

Fireworks are relatively low tech, easy to make and are produced mostly by hand. In many ways the methods used to make them have changed little over the centuries. The work usually entails stuffing powder into tubes or stringing strands of firecrackers, with few concerns about safety.

There are thousands of fireworks factories. In Wanzai county in Jiangxi alone there are 300 sanctioned factories, making more than 3,000 vanities of fireworks. Local officials like them. Their business pays taxes that make up around 40 percent of the budget for local government. The tax payments are often higher than the wages paid to workers.

The fireworks industry is not very well regulated. New factories are built all the time, often near houses and schools. In 2001, 237,000 illegal fireworks factories and shops were closed

The majority of fireworks are made by hand low-paid workers at cramped workshops or even their homes in the Hunan and Jiangxi provinces. Many the workers are farmers who depend on the money to supplement their farming incomes.

Even though the work is dangerous people are anxious for work. One saying in the Jiangxi area goes it is better to die in an explosion than to die of hunger. Most of the workers in Wanzai are women who earn between $37 and $61 a month.

Firework Accidents in China

Raised flower and ball bomb

Explosions in fireworks factories, many of them unlicenced and run with little regard to safety, are common in China. More than a third off all reported fires in China in 2001 were linked to fireworks production.

In December 2001, an explosion at the Panda Export Fireworks Co. in Jiangxi officially killed 14 people, including a small boy who was watching televison in a house next to the factory where the explosion occurred, and injured 61. One resident told the Los Angeles Times, “It’s impossible only 14 people died. At least 10 people died in my village alone, and hundreds more are wounded. That’s not including people killed at the factory.”

The explosion was so strong it leveled houses, uprooted trees and broke window in houses more than a kilometer away. It was believed to have been caused by improper mixing of powerful chemicals used to make display fireworks. It was determined that the blast was set off by an employee that packed a firecracker too violently. The firecracker exploded and ignited stored gunpowder that blew down the factory walls.

In July 2003, a blast at a fireworks factory in the town of Wangkou in Hebei Province in northern China killed 29 people and injuring at least 141. Houses shook so much from the shock waves that many people thought there was an earthquake. An explosion in Hunan in January 2002, killed six people.

In November 2004, a blast at the Changling Firecracker Factory in Guanxi Province in southern China killed 34. Three employees at the factory were arrested for not following safety regulations and having “too many explosives stored in workshops not managed properly.”

In March 2008, fireworks trucked to a desert near Turpan, Xinjiang to be destroyed exploded as they were being dumped into ditch, killing 25 people and leaving five others missing. Television footage showed vehicles burned to a shell and a patches of brown sand left behind by the explosion. One report said 904 boxes of fireworks were scheduled to be destroyed.

In August 2008, a blast at fireworks factory in Aohan Banner in Inner Mongolia killed 17 people an injured six. A similar blast at an illegal factory in Shandong Province in May 2009 killed 13.

Explosions, Fireworks in School, See Education, Government and Public Services

Image Sources: 1, 2, 3) China Labor Watch; 4) Hong Kong Tourism; 5, 6, 7) University of Washington ; YouTube

Text Sources: New York Times, Washington Post, Los Angeles Times, Times of London, National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated April 2012