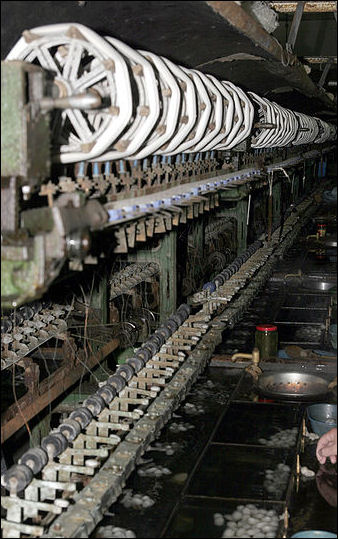

TEXTILE INDUSTRY IN CHINA

silk factoryChina is the world's largest textile, garment and shoe manufacturer and exporter. In the beginning China was known for producing unfashionable clothes for K-Mart and discount stores. Over time the quality of the clothing improved and name brand fashion houses began having their clothes made in China too.

As of 2005, China’s textile companies made 17 percent of the clothes sold in the world in terms of value. As of 2002, clothing and textiles made up 18.6 percent of China’s exports. The value of clothing and textiles exported that year was $98.7 billion, No. 1 in the world. China exported $90 billion worth of textiles in 2004. At one time more than 70 percent of China’s trade surplus was earned in the textile industry. [Source: WTO and OECD]

Competition is the textile industry is very fierce and profit margins are low. It is hard for the companies to reduce costs are more than they already are. Profits are made in volume and keeping lead times minimal to reduce inventories. One of the biggest problems the textile industry has been securing good supplies. The quality of locally made ingredients varies and much has to be imported. Petrochemical fibers are vulnerable to price hikes as the price of oil goes up. Large amounts of cotton is imported. Increased demand by Chinese for cotton has caused the price to rose.

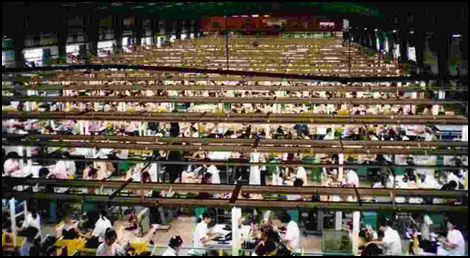

The textile industry supports 90 million workers. The 12 largest textiles companies in China accounted for 36 percent of the textiles and clothing imports in 2004. A vice president at Liz Claiborne told the New York Times, “By and large, anyone in apparel will tell you that you get the best product most reliably for the least amount of money from China.”

China exported around $16 billion worth of textiles to the United States in 2005. Chinese clothes accounts for around 23 percent of the U.S. market. By 2007 when all quotas are to be lifted the Chinese are expected to take over 50 to 80 percent of the market. American textile workers generally earn in two week what Chinese textile workers earn in a year.

Some of the work is quite nasty. Workers at the American Oversea Fur Factory stands knee-deep in steaming vats of dye picking out animal skins with spears and placing them in a pile for 12 hours a day, six days a week for $6 a day plus $150 a month in overtime.

Websites and Sources: China Labor Watch chinalaborwatch.org ; China Labor Bulletin clb.org.hk/en ; China Law Blog on New Labor Laws chinalawblog.com ; Book: Understanding Labor and Employment Law in China (Cambridge University Press, 2009) cambridge.org/us ; Gloomy Photos of Workers zhouhai.com

<

p class="linkbox"> Articles About LABOR IN CHINA factsanddetails.com MIGRANT WORKERS IN CHINAFactsanddetails.com/China ;

See Separate Article INDUSTRIES IN CHINA factsanddetails.com

Success of the Chinese Textile Industry

Shoe factory

The textile industry has thrived not only because of abundant cheap labor but also because of high productivity, logistical smarts and clustering. Many factories are located in clusters and feed off one another and are near ports where they goods can be exported.

China ascendancy will difficult for any other country to challenge. Between 2002 and 2005, the Chinese government invested $21 billion in local textile and manufacturing and 3,800 textile plants were under construction.

Among those who have made fortune here are Dong Ying-Hong, who gave a $9-a-month teaching job in the 1970s to make socks at home and now is the millionaire owner of Zhejiang Socks; and Guo Changqi, the son of a peanut farmer who became the head of the Royal Family Garments factory. the world’s largest T-shirt factory, capable of churning out 10 million T-shirts a year. before he turned 35.

Many of the worlds bra, including push up bras and one made by Maidenform, Victoria Secret and Target are made in China. The export of bras to the United States tripled in 2002.

See Cheap Labor, Labor; Trade, Business and Trade

Chinese Textile Factories

The Chinese textile and clothing export industry is comprised of several hundred manufacturers in 15 provinces, with most of them near the southern coastal ports. Zhejiang Province is home to a number of towns and cities that specialize in a particular item of clothing. Shenzhou is known as the “Necktie Capital” of the world. It produces 40 percent of the world’s neckties. Nearby are Sweater City,” “Kid’s Clothing City,” and “Underwear City.” Buyers place orders for hundred of thousands or millions of items at a time. Qiaotou — the “Button Capital” — has only 64,000 people but it has 380 local factories hat produce more than 70 percent of the buttons for clothes made in China. Songxia produced 350 million umbrellas a year.

Fuan Textile was the second largest exporter of fabric in 2004. Based in Dongguan, it exported $390 million worth of knitted items, two thirds of them sent to the United States, and has a factory with 6,000 employees, 400,000 square meters of factory floor space and 1,600 knitting machines, dying vats and dryers. It is so large it has its own power plant. But its is more than just a factory. It has it own labs, where newer fabrics and machines are developed and tested using sweat simulators and dozens of different kinds of washing machines.

Fuan Textile was founded in 1988 by its Hong Kong parent company. It can make as much 16 million kilograms of dyed fabric and yarn a year. It customers include Victoria’s Secret, J.C. Penney, Liz Claiborn and Wal-Mart

silk factory

Bra rings are produced by 20 Chinese companies in southern China using a machine produced in Guangzhou that cost $65,000. The first company to enter the business made good profits but after competitors entered the prices were driven down by 60 percent.

Chinese Sock Factories

Near Shanghai is the world’s largest sock factory. It produces two million socks a day. Factories in the small coastal factory town of Datang produce nine billion pairs of sock a year — one third of the world’s socks, and enough to provide at least one pair for every person on the planet. Local people call their town “Sock City.” Its annual sock festival draws 100,000 buyers.

Socks are good examples of how the Chinese employ clustering. Datang is able to produce 9 billion pairs of socks a year by employing a profusion of sock related industries, including about 1,000 textile material processors, 4,000 yarn dealers, 300 sewing firms, 100 pressing operations, 300 packagers and 100 forwarders. All these companies support each other and help bring down costs. [Source: Don Lee, Los Angeles Times, November 2005]

With the clustering system, supplies are available and distributors can get the good quickly to customers. If a machine breaks down there are several companies that can help fix it, If packaging prices are too high, several dozen companies are anxious to take on the business and will provide a bid. Pressing is done using heat supplied by ovens that are fed one ton of coal and one ton of wood a day.

Socks are also a good example of how successes in China are driving factories and businesses in other countries to bankruptcy. Three Star, for example, is one of several factories in Datang that produce socks. It pays workers 60 cents an hour, plus room and board, and uses five-hundred $1,000 knitting machines, which require workers to constantly clean lint from the pulleys, plus sew the toe seam by hand.

Nike factory

By contrast factories such as Robin-Lynne in Fort Payne, Alabama — which used to produce 1 out 8 pairs of socks in the world and billed itself “sock capital of the world” — pays workers $10 an hour and uses $25,000 knitting machines that produce a pair of socks with the toe seam automatically in a third of the time as machine used by Three Star.

Three Star produces a pair of socks for 27 cents and makes money. Robin-Lynne, produces a pair of socks for 41 cents and loses money. Between 2000 and 2004, the shipments of socks to the United States have increased from 3 million pairs to 670 million pairs while American sock makers have seen their market share drop from 69 percent to 44 percent.

Chinese Shoe Factories and Pen Towns

Chinese shoes factories, mostly in Guangdong and Fujian provinces, are outfit with the latest machines and regarded as models of efficiency. They produce 5 billion pairs of shoes annually and have wiped out the shoe industry in many other countries. More than 80 percent of the footwear imports in the United States — a billion-shoe-a-year market — come from China.

One of the largest factories in Dongguan produces shoes for Nike, Reebok and other brands. It employs 70,000 people, mostly young women, and has its own movie theater, hospital and fire department.

The Cankun factory in Zhangzhou, opposite Taiwan, is the world’s largest producer of irons and coffee makers. Workers there begin their day, wearing identical yellow shorts, standing on a street before rows of yellow factory, listening to a pep talk.

Wengangm a town in southern Jiangxi with only 70,000 people Province is famous for pens. In 2006, the towns 2,100 businesses produced 7.5 billion brush and metal pens — enough to supply one for every person the planet. The per capita income in the town is $800 a year, about half the national average.

Don Lee wrote in the Los Angeles Times, “Almost everybody in Wengang does something related to pens. Narrow alleys are filled with sounds of grinding metal for pen casings and noxious fume from paint shops. Dozens of pen storefronts on the ground floor of pale two- and three-story buildings are scattered along the main road...Nine times a month, on days marked on the lunar calendar, villagers gather for a large pen fair in a shabby, concrete building in the center of town. Hundreds set up booths or tables, selling bamboo, ox bone and ivory for brushes sticks, and all kinds of animals hair — goat, rabbit, weasel, skunk — for brush tips.”

Nike, Reebok, Adidas and Poor Working Conditions in China

Kohler factory

Nikes are manufactured in Vietnam, China, Indonesia and Thailand. It has been criticized for hiring underage workers, paying subsistence wages, hiring abusive managed and exposing employees to dangerously high levels of toxic chemicals.

Nike produces 78 million shoes a year from contract manufacturers in China. About 160,000 workers in China rely as 2001. Nike says the labor cost for a $85 shoe are about $2.50. If materials are included the cost is $16. If administrative labor is excluded the labor cost are only about $1.

Some Nike factories have been described as "little more than prison labor camps." Employees work 72 hour weeks and can be fired for refusing over time. One study found that workers at factories that make Nikes and Reeboks, monitored in 1995 and 1997, earned as little as 10 cents an hour and toiled for up to 17 hours a day. In response to criticisms, Nike asserts it doesn't make shoes, it subcontract the work.

Responding the criticism Nike promised to raise the age of employment to 18. improve safety use water-based rather solvent-based glues and use machines that do cause serious injuries. Some factories offer free day car and health checks and provide continuing education for their employees.

Adidas has been accused of using slave labor to make soccer balls. According to a lawsuit brought on behalf of dissident Baso Get, political prisoners in China "were coerced into waxing, stitching, and sewing Adidas soccer balls 14-18 hours a day in inhumane conditions" to make soccer balls for the 1998 World Cup.

In 1998, Tim Larimer of Time wrote: "Nike's factories in the region are above average...[We] found them to be clean, brightly lit and well-ventilated. Where the employees have to use foul-smelling glues, there are plenty of fans to carry the fumes.”

The British newspaper The Mail reported that workers in the factory that make Apple’s Ipod get paid as little $50 a month working 15 hour shifts to make the devices.

In response to China's human rights policy, Reebok contracts now prohibit China from using prison or child labor in the production of its goods. In 1993 Levi Straus began a phased out withdrawal of its $40 million contract in China over concerns of human rights. [Source: U.S. News and World Report]

Female Workers at Sport Shoe Factories, See Labor

Furniture Industry in China

Ikea supplier

China is one of the world’s largest furniture makers. Fueled by cheap labor, it went from being a non player to dominating player in the industry in less than 10 years. Imports of furniture rose from 5.5 percent in 1992 to 34.6 percent in 2001.

China exports 40 percent of the furniture it makes, with half the exports going to the United States. Many of the biggest exporters of furniture are located in the Wenzhou area in Zhejiang Province. The industry was devastated by the global slowdown. Furniture was hard hit because the housing crisis kept people from buying new furniture and the economic slowdown cut demand for big ticket items like furniture sets. The industry was also hurt by rising costs for labor, oil and metal.

Factories that produce high-end furniture with elaborate veneer and carving designs employ workers get paid about 40 cents an hour. This allows these factories to produce furniture for American markets at 30 percent less than U.S. furniture companies.

A factory in Dongguan China pays workers about $1,300 a year, which includes meals and housing. Line supervisors get around $5,500 and a plant mangers gets $45,000. The costly building a factory is $7 per square foot. By contrast a factory in Marion, North Carolina workers get about $25,000, line supervisors get around $45,000 and a plant manager gets $65,000. The cost of building a factory is $35 per square foot.

A typical factory began by producing shoddy tables. Quality improved when high quality wood was imported and managers from Taiwan were brought in and upgraded machinery. The large factors have wood workshops, painting and lacquer applying areas, rooms where craft people work and dormitories for workers. Outside are small workshops for suppliers.

Furniture Making in China

Bamboo furniture maker

Describing the work done in a factory in Dongguan, Warren Vieth wrote in the Los Angeles Times: “In the “veneer room,” hundreds of women piece together intricate designs...from thin strips of wood. Fingers flying, they shape veneer into complex patterns of contrasting grains and colors, wooden tapestries meant to transform mere cabinets into objects d’art.”

“Once a piece is completed, it heads down a mile-long, serpentine finishing line with 19 spraying stations and 300 workers, more than twice as many as would be found in a U.S. factory...Each item gets extra sanding, buffing and finishing, attention reserved for only the most expensive furniture en the United States.”

A typical employee works from 7:30am to 8:00pm with lunch and dinner breaks. She works with a team that produces 2,000 drawers a day at a rate of one of every three minutes. The workers start at about $60 a month and earn around $100 a month after two years and live in a dormitory with a screening room for watching television and videos and basketball court.

Bicycle Industry in China

Each year China produces 17½ million bicycles, three times as many bicycles as nearest rivals (Japan and the U.S.). If these bicycles were lined up together they would stretch three quarter of the way around the world. In the Mao and Deng eras China produced more.

At its peak, the Shanghai Forever Bicycle Company alone produced 33.5 million bicycle every year, and one out of every four Chinese rode a bicycle made at this factory. Most of the bikes made by the factory were black one-gear models made from water pipe known as Flying Pigeons. Models exported to the U.S. were called Wind Catchers. Many of the sophisticated road bikes and mountain bikes sold around the globe are made in China.

Many of the sleek collapsible scooters, such as the Razor, Micro, Kickboard and Xootr, that became the rage in the late 1990s and early 2000s were have also produced in China.

Golf Club Manufacturing in China

silk factory in SuzhouDescribing the manufacturing of golf clubs at a factory in Ningpo that employs 500 workers, Jonathon Franzen wrote in The New Yorker, “Grease-blackened machines, operated by male workers...drilled raw steel tubing into a taper and pressed neat rings of crimp into the resulting shaft. Female workers painted glue onto strips of graphite composite which were then rolled onto the shafts and heat-bonded to them. One heavy-duty machine stamped sheet steel into hollow driver heads; on either side of a different machine, two men used tweezers to insert and remove driver faces into which the machine pressed horizontal grooves.”

”After stamping, the driver heads were milled in a dimly lit room full of water-cooled grinding machines by well-muscled men in masks...Upstairs, in a room filled with shockingly intense paint fumes, tough-looking girls with big hair and extreme boots and stockings were inspecting the finish on driver shafts and buffing away small flaws. Other young people sandblasted clubheads, applied decals to the shafts, hand-tinted the grooves of logos, and injected glue into driver heads to keep the residual grit in them from rattling.” The workers lived in a factory dormitory, ate at a company cafeteria and were payed an average of $200 a month.”

Vuvuzelas

China is also the leading producer of the vuzuzelas, the long plastic horns that made such a racket at the World Cup in South Africa in 2010 and kaffiyeh scarves popularized by Yassar Arafat and now of symbol of Palestinian resistance.

About 90 percent of vuvuzelas are made in Guangdong and Zhejiang Provinces. Initially known sold as “fan horns” but now known in China as “wuwuzula,” they cost about 30 cents a piece to make. They had been made for years in China but suddenly began selling in big numbers before the World Cup. The owner of Guang Da Toys in Yiwu told the Los Angeles Times, “We sold about 150,000 of them every month from November to January. I couldn’t imagine it would become so popular.” The owner of factory with 90 workers that made more than 1 million of them as well as wiffle balls and watering cans for plants, said, “You can say we qualified for the World Cup. It makes me proud to hear the horns on TV.”

Noodle factory

Image Sources: 1, 3, 5, 7) China Labor Watch; 2, 6, 8) Nolls China website http://www.paulnoll.com/China/index.html ; 4) University of Chicago : also wiki commons

Text Sources: New York Times, Washington Post, Los Angeles Times, Times of London, National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated April 2011