APPLE MANUFACTURING IN CHINA

Many Apple's devices and many of their parts are manufactured in China at huge factories owned electronics suppliers along the southeastern coast and lately further inland. Much of Apple’s manufacturing, including the assembly of iPads and iPhones, is done in China by Foxconn (See Below).

In 2014, Apple hired Doug Guthrie, the departing dean of the George Washington University business school, to help the company navigate China, a country he had spent decades studying.One of his first research projects was Apple’s Chinese supply chain, which involved millions of workers, thousands of plants and hundreds of suppliers. The Chinese government made that operation possible by spending billions of dollars to pave roads, recruit workers, and construct factories, power plants and employee housing. Mr. Guthrie concluded that no other country could offer the scale, skills, infrastructure and government assistance that Apple required. Chinese workers assemble nearly every iPhone, iPad and Mac. Apple brings in $55 billion a year from the region, far more than any other American company makes in China. “This business model only really fits and works in China,” Mr. Guthrie said in an interview. “But then you’re married to China.” [Source: Jack Nicas, Raymond Zhong and Daisuke Wakabayash, New York Times, May 17, 2021]

See Separate Articles APPLE IN CHINA: HISTORY, PRODUCTS AND KOWTOWING TO BEIJING factsanddetails.com; FOXCONN: ITS FACTORIES, WORK CONDITIONS AND BUSINESS factsanddetails.com

RECOMMENDED BOOKS: “Dying for an iPhone: Apple, Foxconn, and The Lives of China's Workers” by Jenny Chan , Mark Selden , et al. Amazon.com; “Factory Girls: From Village to City in a Changing China” by Leslie T. Chang, Susan Ericksen, et al. Amazon.com;“Start with China: How Apple Uses Cheap Labor to Make Billions” by Smith Murphy and Jones O’kelly Amazon.com; “Apple- Foxconn Study” by Bankim Chandra Pandey Amazon.com “The Great U.S.-China Tech War” by Gordon G. Chang, Al Kessel, et al. (2020) Amazon.com; “The Transpacific Experiment: How China and California Collaborate and Compete for Our Future” by Matt Sheehan Amazon.com;

History and Growth of Apple Manufacturing in China

David Barboza wrote in the New York Times: “In a bid to lower costs, some of the biggest American technology companies, including Compaq, Dell and Hewlett-Packard, began dismantling their domestic manufacturing in the 1980s and moving work overseas, largely to Asia. Not Apple. The company’s co-founder, Steven P. Jobs, believed that software and hardware development had to be closely integrated.[Source: David Barboza, New York Times, December 29, 2016]

“Rather than close plants, Apple decided to build them — in Colorado, Texas and California. Apple would maintain some of them long after Mr. Jobs left the company in 1985. The plants were highly automated, with the walls painted white, just as Mr. Jobs liked them, and they were promoted as a symbol of American ingenuity. “This is a machine that is made in America,” Mr. Jobs trumpeted in 1984, after Apple opened a manufacturing facility in California to produce the Macintosh personal computer.

“Finances forced Apple to change course. As Mac sales plummeted and inventories began to bulge in the mid-1990s, Apple had to embrace outsourcing, something with which it had only just experimented. After Mr. Jobs returned to the company in 1997, he turned to his new operations chief, Mr. Cook, who had recently joined from Compaq, to figure out how.

“When Apple first moved into China, the country was largely a low-cost production site. It quickly evolved into one of the world’s biggest consumer markets, with more than a billion potential customers. But Apple initially had to take the “Hong Kong U-turn” to get its products into the hands of Chinese consumers. In 2005, Apple’s best-selling portable music device, the iPod, was manufactured in southern China. To comply with the country’s stringent rules, iPods were loaded onto a cargo ship and sent to Hong Kong. Often, when the ship arrived, it was simply turned around and sent back to China." [Source: David Barboza, New York Times, December 29, 2016]

“Apple and other multinationals wanted a better system. By the time Apple released the iPhone in 2007, China faced growing pressure to loosen its restrictions and give global companies easier access to its market. Apple and other companies believed that shipping goods to Hong Kong was a waste of time and energy. They wanted to send goods from the factory gate in China directly to their stores and distribution centers inside the country.

Foxconn and Apple

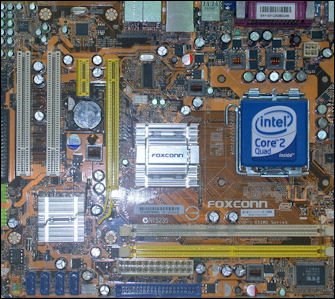

Much of Apple’s manufacturing in China as we said is done by Foxconn. Established in 1974 by the Taiwanese industrialist Terry Gou, and headquartered in Tucheng, New Taipei City, Taiwan, Foxconn is the world’s largest technology manufacturer and service provider. While the company is based in Taiwan, it is the largest private employer in mainland China and one of the largest employers in the world.

As of the early 2010s, Foxconn had at least 250,000 people working on Apple products on the mainland, according to the group Students and Scholars Against Corporate Misbehavior, a Hong Kong-based nongovernmental organization that has been sharply critical of conditions for Apple workers. Their take-home pay was $150 a month — meaning it would take four months' wages to buy the cheapest model iPad. Many Apple products are made at a massive Foxconn factory in Shenzhen. A great deal of pressure has been put employees at these factories to stay quiet about the products so as not to compromise marketing plans. In July 2009, one worker killed himself after being accused of taking an iPhone. [Source: Barbara Demick, Los Angeles Times, October 20, 2011]

In the late 1990s and early 2000s, under the direction of Tim Cook, David Barboza wrote in the New York Times: “ Apple shifted more business to Foxconn, then an up-and-coming Taiwanese contract manufacturer that had started to gain a following among big American brands like Compaq, IBM and Intel. The partnership freed up Apple to focus on its strengths — design and marketing. Apple would come up with a new idea, and Foxconn would find ways to produce millions of units at a low cost. “They have brilliant tooling engineers, and they were willing to invest a lot to keep pace with Apple’s growth,” said Joe O’Sullivan, a former Apple executive who worked in Asia.

“When Apple’s sales took off after the introduction of the iPod in 2001, Foxconn had the heft and expertise to meet the demand that accompanied each hit product. Foxconn’s factories could quickly produce prototypes, increase production and, during peak periods, hire hundreds of thousands of workers. “Foxconn’s founder, the Taiwanese billionaire Terry Gou, provided political clout. Over the years, he frequently visited China to meet local officials and members of the decision-making Politburo to lobby for subsidies, cheap land, workers and infrastructure for facilities that churned out iPods, iPads and iPhones.

“As China’s largest private employer, Foxconn, has enormous leverage in the negotiations for those incentives. The company’s size and scale — and the sway that they afford in China — is connected to Apple. Foxconn is Apple’s largest supplier. Apple is Foxconn’s largest customer. [Source: David Barboza, New York Times, December 29, 2016]

“The two companies are intertwined. “The reason Foxconn’s so big is Terry Gou,” said Tony Fadell, a former Apple executive who helped design the iPod. “He said he’d create the manufacturing, and the Chinese government would give him some of the money to do it. As Terry grew with the Apple business, no one else could compete.”

Zhengzhou: iPhone City

Reporting from Zhengzhou, a city of 12.5 million in an impoverished region of China about 600 kilometers south of Beijing, David Barboza wrote in the New York Times: “A vast, boxy customs center acts as a busy island of commerce deep in central China. Government officers, in sharply pressed uniforms, race around a maze of wooden pallets piled high with boxes — counting, weighing, scanning and approving shipments. Unmarked trucks stretch for more than a mile awaiting the next load headed for Beijing, New York, London and dozens of other destinations. The state-of-the-art facility was built in the mid 2010s to serve a single global exporter: Apple, now the world’s most valuable company and one of China’s largest retailers. [Source: David Barboza, New York Times, December 29, 2016]

Running at full tilt, the factory here, owned and operated by Apple’s manufacturing partner Foxconn, can produce 500,000 iPhones a day. Locals now refer to Zhengzhou as “iPhone City.” The local government has proved instrumental, doling out more than $1.5 billion to Foxconn to build large sections of the factory and nearby employee housing. It paved roads and built power plants. It helps cover continuing energy and transportation costs for the operation. It recruits workers for the assembly line. It pays bonuses to the factory for meeting export targets.

“All of it in support of iPhone production. “We needed something that could really develop this part of the country,” said Li Ziqiang, a Zhengzhou official. “There’s an old saying in China: ‘If you build the nest, the birds will come.’ And now, they’re coming.” When the factory opened, Apple was Foxconn’s only customer here. Even now, the American technology company accounts for almost all of the production at the Zhengzhou plant, where about half of the world’s iPhones are made. Apple is also the main exporter using the customs facility here.

“A crushing work force begins arriving for the early shift at 6:30 a.m. They travel by foot, by bus, by motor scooter and even by pedicab. They file steadily into dozens of factory sites, spread out across 2.2 square miles. At the peak, some 350,000 workers assemble, test and package iPhones — up to 350 a minute.

“A 32-gigabyte iPhone 7 costs an estimated $400 to produce. It retails for roughly $649 in the United States, with Apple taking a piece of the difference as profit. The result: Apple manages to earn 90 percent of the profits in the smartphone industry worldwide, even though it accounts for only 12 percent of the sales, according to Strategy Analytics, a research firm. [Source: David Barboza, New York Times, December 29, 2016]

“As the Zhengzhou operation shows, China not only provides a large pool of labor; it also offers incentives that would be difficult to replicate in the United States or anywhere else. The trove of benefits in Zhengzhou flows through the production process for the iPhone, from the factory floor to the retail store. Foxconn receives a bonus when it meets targets for exports. Those subsidies, according to the government records, totaled $56 million in the first two years of production, when the factory was exclusively dedicated to the iPhone. The bonus is small on each of the tens of millions of iPhones produced during that period. But the subsidies add up: The government records list more than a dozen other forms of financial aid at the Zhengzhou operation.

Perks Given by Zhengzhou to Get Apple to Come

David Barboza wrote in the New York Times: The operation at Zhengzhou “is part of a hidden bounty of perks, tax breaks and subsidies in China that supports the world’s biggest iPhone factory, according to confidential government records reviewed by The New York Times, as well as more than 100 interviews with factory workers, logistics handlers, truck drivers, tax specialists and current and former Apple executives. The package of sweeteners and incentives, worth billions of dollars, is central to the production of the iPhone, Apple’s best-selling and most profitable product. [Source: David Barboza, New York Times, December 29, 2016]

Zhengzhou fought fiercely against other Chinese cities to get Apple to cone. “After the first iPhone was rolled out in 2007, Foxconn moved to expand production and began scouting new locations around China — unleashing a fierce competition among cities eager for the business. Officials from various regions camped out at hotels in Shenzhen, where Foxconn had its main operations. “These have become like Olympic competitions,” said Gao Yuning, who teaches public policy at Tsinghua University in Beijing.

“In August 2014, the city’s top leaders held a special meeting to discuss “deepening collaboration” with Foxconn, according to the government records obtained by The Times. They crowed that Zhengzhou was the “biggest production base for Apple iPhone worldwide.” There were 94 production lines producing the iPhone 6 and iPhone 5s, and the government said about 230 million smartphones had already been exported from Zhengzhou, making it one of the nation’s crucial export centers. Production capacity had reached half a million iPhones a day. The city’s tax revenue was rapidly rising. “Officials had a name for it all: “Zhengzhou Speed.”

“Apple’s labor force, the size of a national army, relies heavily on the generosity of the Zhengzhou government. As part of its deal with Foxconn, the state recruits, trains and houses employees. Provincial officials call townships and villages to ask for help finding potential workers. “Every city’s department of labor and ministry of human resources is involved,” said Liu Miao, who runs a private recruiting center in Zhengzhou. The government pays recruiters a subsidy for every worker they hire, Mr. Liu said. “If the demand is high, then they will pay more,” he said. “If the demand is low, then the payment will be low, too.”

“The Zhengzhou government eliminated corporate taxes and value-added taxes that Foxconn pays for the first five years of production; they are half the usual rate for the next five. The city lowered Foxconn’s social insurance and other payments for workers, by up to $100 million a year. The customs operation is also in a so-called bonded zone, an area that China essentially considers foreign soil, subject to different import and export rules. This setup allows Apple to sell iPhones more easily to Chinese consumers.

“Benefits supplied to Foxconn by the Zhengzhou government: 1) Construction: Built and partly financed the construction of a huge manufacturing complex at a cost of $600 million and spent around $1 billion to build housing that could accommodate hundreds of thousands of workers. 2) Energy: Provides a discount that reduces the cost of power by 5 percent annually and built infrastructure, including power generators and a 24-kilometer pipeline. 3) Finances: Eliminated corporate taxes and value added taxes for five years, then halved the usual rate for the next five years and granted a $250 million loan from the municipal treasury. 4) Workers: Helps recruit and train workers, as well as paying subsidies for new hires. 5) Logistics: Offers bonuses tied to the growth of exports and pays out a subsidy to help defray the cost of shipping goods.

How Apple Uses China to Avoids Taxes

David Barboza wrote in the New York Times: China also functions as a base for Apple’s global tax strategy. In the Zhengzhou bonded zone, typically at customs, Foxconn sells the finished iPhones to Apple. After purchasing the iPhones, Apple then resells the goods to Apple subsidiaries. The process largely takes place electronically. [Source: David Barboza, New York Times, December 29, 2016]

“The process also plays out with other Apple goods that are produced in the country. Apple can assign some profits on these goods to an affiliate in Ireland, a tax-advantageous locale, according to a 2013 American congressional report on the company’s tax practices. It is a practice commonly employed by many big technology brands and is not unique to China. “U.S. multinationals are the world leaders in tax avoidance strategies,” said Edward D. Kleinbard, the former chief of staff of the congressional Joint Committee on Taxation. “In doing so, they create stateless income — income that has become unmoored from the countries to which it has an economic connection.”

“According to the congressional report, the process allowed Apple to move tens of billions of dollars offshore and substantially reduce its tax bill, which one senator called the “holy grail of tax avoidance.” The European Union in August ordered Ireland to claw back more than $14.5 billion from Apple in unpaid taxes from a decade-long period. Apple said it follows all applicable tax rules, insisting that the company pays all its taxes. The company said it had made some changes to its tax procedures to comply with new laws, including registering a subsidiary in Ireland that previously had no tax jurisdiction. It is appealing the ruling in the European Union.

Criticism of Apple Manufacturing in China

Apple requires its suppliers to abide by a code of conduct in which certain safety standards have to be met and workers are restricted from over 60 hours a week. The company performed an audit of more than 100 of its production facilities in 2009 and found that half its partner facilities violated the policy of workers working over 60 hours a week. Other audits of Apple have found labor, health, health and environmental violations, including instances of underage labor and discrimination based on pregnancy.

In January 2012, Apple disclosed a list of its suppliers for the iPhone, iPad and other popular devises for the first time. The 2012 “Supplier Responsibility Progress Report” documented 229 audits throughout its supply chain in 2011 by Apple Inc. In its report, Apple found that 78 of the company’s suppliers complied with anti-discrimination standards it has set for them. But only 61 percent of them had systems in place to prevent discrimination from happening. Nearly all — 97 percent — prevented underage labor. But only 72 percent had policies in place keep it from happening. Just 38 percent of the suppliers observed Apple’s working-hours policies, and 69 percent followed its code for wages and benefits. In all, the audits found 74 percent of the suppliers to be in overall compliance with Apple’s policies. Examples of violations included testing job candidates for Hepatitis B, conducting pregnancy tests and exceeding weekly limits of 60 working hours. Apple said 109 facilities it audited did not pay proper overtime wages.

Barbara Demick wrote in the Los Angeles Times, “In a report released in September 2011 titled "iSlave behind the iPhone," Students and Scholars Against Corporate Misbehavior (SACOM) said the extraordinary demand for Apple products was putting great pressure on workers, who often are on their feet for 10-hour shifts, live in military-style barracks and are penalized if they don't work overtime. Turnover is high, at least 19 workers have committed or tried to commit suicide, and three workers died in a May 20 explosion in a workshop operated by Foxconn in Sichuan province, the group said. [Source: Barbara Demick, Los Angeles Times, October 20, 2011]

Environmental groups have also criticized Apple for failing to monitor Chinese suppliers whose plants discharge hazardous wastewater and gases into residential areas. One of the suppliers, Catcher Technology, announced this week that it had partly closed a factory that made high-end metal casings for the MacBook Air because of a "strange odor" that drew complaints from nearby residents. Although the accusations have had some coverage in the United States, there's been hardly any in China.

Poor Working and Living at an Chinese Apple- Foxconn Factory

In Shenzhen and Chengdu a joint Foxconn workforce of 500,000 provided labor for Apple in the early 2010s. Interviews by center for Research on Multinational Corporations and the human rights group Students & Scholars Against Corporate Misbehavior with mainly migrant employees and managers said that many of them were have been forced to work under Dickensian conditions that would be considered shocking in the west. "Sometimes my roommates cry when they arrive in the dormitory after a long day," one 19-year-old girl told investigators. "It's difficult to adapt to this work and hard to be away from your family." The girl, named Li, had worked at the newest factory opened by Foxconn at that time. She said she was attracted, like many of her colleagues, by government advertisements promising work and good pay. [Source:Gethin Chamberlain, The Guardian, April 30, 2011]

Gethin Chamberlain wrote in The Guardian, “For the first few days at the factory, Li said that she and her colleagues — most seem to be aged 18-20 — were put through military drills by former soldiers: "They made us do marching and standing still and walking. It was very boring." The dormitories where she and most others live offer little comfort. Up to 24 people can share one room and the rules are strict, even prohibiting the use of a kettle or a hairdryer. One worker who did was forced to write a confession letter: "It is my fault. I will never blow my hair inside my room. I have done something wrong. I will never do it again." [Source: Gethin Chamberlain, The Guardian, April 30, 2011]

Many workers interviewed claimed that they were regularly required to work far in excess of the 36 hours of overtime per month that Chinese law — and therefore international labor law — permits. At Chengdu it was claimed that anything between 60 and 80 hours of overtime a month was normal. One worker produced a payslip showing 98 hours of extra time in a single month — nearly three times the legal maximum and in breach of Apple's own code of conduct. The rule that employees should have one day off in seven is often flouted, some claimed.

Others said that if they missed targets, they had to work through their lunch breaks to make up for it. When they do get a day off, they spend much of it catching up on sleep. During work, some employees claimed they were forbidden to speak to each other and some were forced to stand for hours without a break. Foxconn, a Fortune 500 company, does not deny it breaks the overtime laws, but claims that all overtime is voluntary. Workers who step out of line can be publicly humiliated, it is alleged. "When a worker makes a mistake, when he talks or laughs loudly, he will be humiliated," a production worker said. "Sometimes you have to stand like a soldier in front of everybody. It is a loss of dignity and means an extra pressure for the worker."

A typical working day in Chengdu means getting up at 6.30am, catching a bus for the 30-minute ride to the factory at 7.10am and attending a compulsory — but unpaid — assembly at 8.10am, before starting work at 8.30am. Shifts, including overtime and breaks, end at 8.30pm. Night shifts follow a similar pattern; with demand for the iPad2 outstripping supply in many countries, this is a round-the-clock operation. Demand for the first iPad was so intense that workers claim they had to put in a seven-day week during peak production period.

"We only had a rest day every 13 days," claimed one. "And there was no overtime premium for weekends. Working for 12 hours a day really made me exhausted." Sacom says the company's initial response to the suicides was to bring in monks to exorcise evil spirits. The chief executive later suggested workers were committing suicide to secure large compensation payments for their families. Workers were even asked to sign a document promising not to commit suicide and pledging that if they did their families would not claim more compensation than the legal minimum.

Foxconn Worker Commits Suicide Over Missing iPhone in China

In July 2009, an employee at Foxconn factory that makes Apple iPhones killed himself after his house was raided and he was allegedly beaten up following the disappearance of an iPhone prototype. The dead worker, Sun Danyong, 25, was responsible for sending iPhone prototypes to Apple. After he reported to his bosses that he was missing a unit early last week his apartment was then raided, and he was beaten and imprisoned by security guards, his friends told the Southern Metropolis Daily. Three days after reporting the missing iPhone Sun jumped from the 12th floor of his apartment building. [Source: Alexandra Topping The Guardian, July 22, 2009]

Jill Tan, an Apple spokeswoman in Hong Kong, said: “We are saddened by the tragic loss of this young employee...We require our suppliers to treat all workers with dignity and respect.” Sun, like other employees dealing with Apple's new products, was under huge pressure to maintain a high-level of secrecy over the gadgets. The launches of new Apple products produce huge anticipation and excitement in fans and the media and the technology giant is constantly targeted by journalists, fans and its competitors who want to uncover its secrets.

Before his death Sun wrote in text messages that he had been beaten and humiliated during interrogations. Gu Qinming, the security chief who led the raid on Sun's house was suspended and turned over to the police, Foxconn said in a statement. Gu denied hitting Sun, adding that he thought the employee was lying about the missing device. After the raid failed to uncover the missing iPhone, Sun had been ordered to go to Gu's office, Gu told the Southern Metropolis Daily. “I got a bit agitated. I pointed my finger at him and said that he was trying to shift the blame,” Gu was quoted as saying. I was a little angry and I pulled his right shoulder once to get him to tell me what happened. It [the beating] couldn't have happened,” he told the paper.

Foxconn executive Li Jinming said in a statement that Sun's death revealed that the company had to work harder to help employees deal with psychological pressures. “Sun Danyong graduated from a good school. He joined the company in 2008. He had an extremely bright future. The group and I feel deep pain and regret when a young person dies like this,” he said.

Four Workers Killed in Explosion at Chinese Factory That Makes Ipads

In May 2011, three workers were killed and 15 were injured in an explosion in the workshop of a factory in Chengdu owned by a supplier to Apple and other electronic companies such as Hewlett-Packard, Dell and Sony. According to the Wall Street Journal the factory makes Ipads and is run Hon Hai Precision Industry (Foxconn). The circumstances of the explosion and deaths were largely hidden. Two weeks after the explosion, there were only preliminary reports of what happened. Apple doesn't even publicly acknowledge the iPad is made in Chengdu. What is known is that one of the more primitive of industrial problems sparked the explosion: A metal polishing shop was improperly ventilated or cleaned, dust collected in the air or on surfaces, and then, in a moment of considerable violence, the dust ignited.

John Bussey wrote in the Street Journal, “Hon Hai said it investigated the accident and resumed operations at its polishing workshops after improving ventilation and other safety-related practices. Apple says it is "working closely with Foxconn to understand" what happened. And the Chinese government, barely raising an eyebrow, has chided Hon Hai for not paying enough attention to safety. In China, where industrial accidents are frequent by-products of headlong, government-led development, this was a notable moment of the pot calling the kettle black.

In the U.S., where nearly 150 people have been killed and more than 850 injured since 1980 in dust explosions similar to Chengdu's, businesses have been shut down for violating safety rules. In 2007, the Occupational Safety and Health Administration launched a national inspection program that targeted facilities that handle combustible dusts, and it has since held open meetings with companies to discuss solutions. This sort of national standard-setting is rare in places like China, where foreign companies would likely welcome it. The accident in Chengdu was tragic, but Apple may have gotten off easy this time. If the body count had been 103 instead of three, global public opinion would have been more mightily stirred. And in that instance, an arm's length would have proved little protection for the company and its brand.

Pollution in China Connected to Apple

In August 2011, Reuters reported: “Chinese environmental groups accused Apple Inc of turning a blind eye as its suppliers pollute the country.Toxic discharges from "suspected Apple suppliers" have been encroaching on local communities and environments, a coalition of environmental organizations said in a 46-page report alleging efforts to conceal pollution. "The large volume of discharge in Apple's supply chain greatly endangers the public's health and safety," said the report, issued on the website of the Beijing-based Institute of Public and Environmental Affairs. The report alleges that 27 suspected Apple suppliers had severe pollution problems, from toxic gases to heavy metal sludge. In one case, the report said, a nearby village experienced a "phenomenal rise in cases of cancer." [Source: Reuters, Michael Martina, August 31, 2011]

Apple has decided to "take advantage of loopholes" in developing countries' environmental management systems to "grab super profits," it said. Apple does not disclose who its suppliers are. The environmental groups said public documents and five months of research and field investigation led to the findings in the report. "A large number of IT supplier violation records have already been publicized; however, Apple chooses not to face such information and continues to use these companies as suppliers. This can only be seen as a deliberate refusal of responsibility," the report said.

This is not the first time Apple has been targeted for environmental infractions and its secretive supply chain management in Chinese factories, where it assembles most of its products.In January, several of the same non-governmental organizations issued a report alleging woeful environmental records for the iPad and iPhone maker's China-based contract manufacturers. In February, workers at a Taiwanese-owned factory in eastern China making touch screens on contract for Apple aired their grievances over a chemical poisoning after using N-Hexane, a toxic solvent.

In a company report released in February 2011, Apple said that 137 workers were poisoned by n-hexane. n January 2011, anti-pollution activists accused the firm of being more secretive about its supply chain in China than almost all of its rivals. [Source: Tania Branigan, The Guardian February 15, 2011]

Child Labor at Apple Factories in China

In a company report released in February 2011, The Guardian reported, Apple said it found 91 children working at its suppliers in China 2010, nine times as many as the previous year, and 137 workers were poisoned by n-hexane. The company also said less than a third of the facilities it audited were complying with its code on working hours. [Source: Tania Branigan, The Guardian February 15, 2011]

The report says Apple found 91 children working at 10 facilities. The previous year it found 11 at three workplaces. It ordered most to pay the children's education costs but fired one contractor which was using 42 minors and had "chosen to overlook the issue", the company said. It also reported the vocational school that had arranged the employment to the authorities for falsifying student IDs and threatening retaliation against pupils who revealed their ages. Apple said it had strengthened its checks on age because of concerns about the falsification of ages by such schools and labor agencies. It also audited 127 facilities last year, mostly for the first time, compared with 102 in 2009.

The report showed a marked decrease in compliance on working hour requirements of a maximum 60-hour week with one day off. In 2009, only 46 percent met the standard; last year that fell to 32 percent . Only 57 percent were compliant with its code on preventing working injuries and 70 percent or fewer met standards on air emissions, managing hazardous substances, and environmental permits and reporting. But there were some signs of improvement in other areas. Compliance on wages and benefits improved from 65 percent in 2009 to 70 percent. The report also said that 99 percent of facilities met its freedom of association requirements. But independent unions are not allowed on the Chinese mainland and Geoff Crothall, of Hong Kong's China labor Bulletin, said: "It is Henry Ford-style freedom of association: You can have any union as long as it is [in] the Associated Federation of Trade Unions."

Image Sources: Wiki Commons

Text Sources: New York Times, Washington Post, Los Angeles Times, Times of London, Yomiuri Shimbun, The Guardian, National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated May 2022