WOOL

freshly shorn wool Wool is animal hair made of keratin, an animal protein also found in human hair, finger nails, feathers and horns. Although wool is mostly associated with sheep it also come from other animals such as Bactrian camels, llamas, alpacas, yaks, Cashmere goats and mohair-producing Angora rabbits and Angora goats. In most cases these animals have developed coats of wool to keep them warm in the winter and humans have bred them to produce wool in quantities and quality fit for human use. [Source: Nina Hyde, National Geographic, May 1988 ╤]

Raw wool (or grease wool) straight from the sheep often contains as little as 50 percent wool. The remainder is wool grease, burs, seeds, other vegetable matter, body salts and dirt. The quality of wool is affected by things like the age, nutritional intake, stress level and sex life of the sheep. Old sheep, for example, get loose teeth, which affects their ability to eat and the lack of nutrition decreases the value of their wool.

Wool absorbs moisture, resists flames, and insulates against heat and cold. The secret behind these traits is the structure of individual wool fibers. Unlike cotton or silk, wool fibers have downward pointing scales, sort of like those on a pine cone. These fibers easily get hooked together and tangled, trapping air and making the wool warm. Another reason wool is warm is that can drawn perspiration away from the body.Although wool's scaly surface tends to repel water, the fiber core absorbs up to 30 percent of its weight in liquids (compared to 8 percent for cotton and 2 percent for some synthetics).

Wool is used to make clothing, blankets, and felts. It in cold places in keeps people warm, in rainy areas it sheds water and in warm areas it can be used for protection from dry heat and glaring sun. Wool grease, which lubricates growing wool fibers, is the source of lanolin, used in cosmetics and pharmaceuticals.

Websites and Resources: Sheep 101 sheep101.info ; American Sheep Industry Association sheepusa.org ; Australian Wool Innovation Limited wool.com ; Australian Wool Exchange awex.com.au ; Wikipedia article wikipedia.org/wiki/Wool ; Sheep breeds 139.78.104.1/breeds/sheep ; Sheep magazine sheepmagazine.com/ ;

World’s Top Wool Producing Countries

yarn World’s Top Producers of Wool, Greasy (2019): 1) China: 341120 tonnes; 2) Australia: 328608 tonnes; 3) New Zealand: 151707 tonnes; 4) Turkey: 70587 tonnes; 5) United Kingdom: 70428 tonnes; 6) Morocco: 58696 tonnes; 7) Iran: 58559 tonnes; 8) Russia: 50211 tonnes; ) South Africa: 47039 tonnes; 9) India: 46021 tonnes; 10) Pakistan: 44645 tonnes; 11) Argentina: 42000 tonnes; 12) Turkmenistan: 39923 tonnes; 13) Kazakhstan: 39492 tonnes; 14) Uzbekistan: 35115 tonnes; 15) Algeria: 35089 tonnes; 16) Uruguay: 26557 tonnes; 17) Indonesia: 25365 tonnes; 18) Spain: 22029 tonnes; 19) Syria: 18576 tonnes [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org. A tonne (or metric ton) is a metric unit of mass equivalent to 1,000 kilograms (kgs) or 2,204.6 pounds (lbs). A ton is an imperial unit of mass equivalent to 1,016.047 kg or 2,240 lbs.]

World’s Top Producers (in terms of value) of Wool, Greasy (2019): 1) China: Int.$1313638,000 ; 2) Australia: Int.$1265455,000 ; 3) New Zealand: Int.$470691,000 ; 4) United Kingdom: Int.$271365,000 ; 5) Turkey: Int.$250428,000 ; 6) Morocco: Int.$250112,000 ; 7) Russia: Int.$193360,000 ; 8) Iran: Int.$188943,000 ; 9) Pakistan: Int.$175003,000 ; 10) Argentina: Int.$161740,000 ; 11) South Africa: Int.$161351,000 ; 12) Turkmenistan: Int.$161024,000 ; 13) Kazakhstan: Int.$152082,000 ; 14) India: Int.$145901,000 ; 15) Uzbekistan: Int.$135226,000 ; 16) Algeria: Int.$133697,000 ; 17) Uruguay: Int.$118251,000 ; 18) Indonesia: Int.$96636,000 ; 19) Azerbaijan: Int.$61981,000 ; 20) Iraq: Int.$58280,000 ; [An international dollar (Int.$) buys a comparable amount of goods in the cited country that a U.S. dollar would buy in the United States.]

Top Wool-Producing Countries in 2008 (Production, $1000; Production, metric tons, FAO): 1) Australia, 687038 , 407881; 2) China, 619335 , 367687; 3) New Zealand, 367032 , 217900; 4) Iran (Islamic Republic of), 126330 , 75000; 5) United Kingdom, 104433 , 62000; 6) Argentina, 101064 , 60000; 7) Russian Federation, 90100 , 53491; 8) Syrian Arab Republic, 84220 , 50000; 9) India, 78156 , 46400; 10) Sudan, 77482 , 46000; 11) South Africa, 75798 , 45000; 11) Uruguay, 75798 , 45000; 13) Turkey, 74393 , 44166; 14) Pakistan, 69060 , 41000; 15) Morocco, 67376 , 40000; 16) Kazakhstan, 59291 , 35200; 17) Spain, 48403 , 28736; 18) Algeria, 42110 , 25000; 19) Indonesia, 41099 , 24400; 20) Uzbekistan, 40053 , 23779;

Types of Wool

dyed wool Wool from a live sheep is called fleece. It is used to make blankets, felts and flannels. When wool is pressurized, heated and soaked with water it turns to felt. It can be used for everything Mongolian tents to tennis balls. Lamb's wool is taken from lambs six to eight months old. Pulled wool comes from a sheep that have died or been slaughtered. Sheepskin and lambskin are used in linings of gloves, garments, handbags, parchments, and textile-mill rollers.

Raw wool is often classified by the age of the sheep from which is wool is taken and divided into three major grades: fine, medium and coarse. and the finest wools, from the goats of Tibet, Kashmir, and the Pamir mountains, and the endangered vicuña of the Peruvian Andes, are made into expensive sweaters and shawls. ╤

Wool is sometimes categorized as apparel wool or carpet wool. The latter is generally coarser and longer than the former. Most of the wool produced is apparel wool with short fibers. It sells for a higher price than carpet wool and produces woolen fabrics are thick, with a fuzzy surface. Worsted wools are made with from thinner, longer fibers. They produce fabrics that are crisper and have a smoother surface.

Felt is made by subjecting piles of loose wool fiber to heat, moisture and pressure. It is easier to make than woven cloth. It was probably first recognized by cave dwellers who noticed the permanent matting that occurred when they wore the fur side of their pelts against their skin.

In the old days felt was made from fluffed wool, which is doused with water, rolled around a pole and then wrapped with a freshly killed yak skin. This bundle, which looks sort of like a rolled up carpet, is dragged around behind a horse for hours until the wool fibers compress enough to become felt. If the wools is not washed properly felt smells like cattle dung. [Source: Nina Hyde, National Geographic, May 1988]

One of the worst's most prized luxury fabrics is Escorial wool, a revolutionary new natural fiber that is extremely soft and light and has a lycra-like crease-resistant stretch. Named after the famous palace built by King Philip II, it is made from sheep that originated in the Atlas Mountains of Morocco, were breed at Escorial palace, and were saved from extinction by a Scottish framer in Tasmania.

Weaving and Cloth

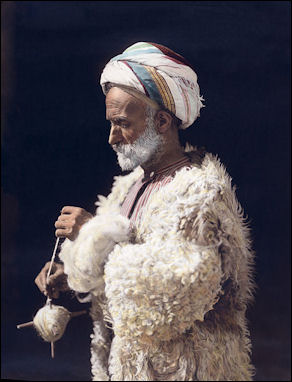

Ramallah wool spinner Weaving is the interlocking at right angles of two sets of fibers to make cloth or a similar material. Spinning is the process by which fibers are drawn and twisted into string, yarn or thread. These tasks have traditionally been done at home by women with looms and spinning devices. The advantage with working at home is that women could work and care for their children at the same time and do weaving and spinning when they are not doing other chores.

To make yarn the old-fashion way: 1) After a sheep is sheared the wool fibers are cleaned and straightened by carding with a toothed card (a sort of brush with stiff bristles). 2) The wool is then rolled between two cards to produce a thin fiber-like piece of wool called a sliver. 3) The sliver is placed on a spike called a distaff. 4) A strand of wool is then pulled off and a weight known as whorl is attached to it. 5) The strand is twisted into a thread by spinning it with the thumb and forefinger. Since each thread is made this way, you can how time consuming it must have been to make a piece of cloth.

To make cloth the old-fashion way: 1) Threads are placed on a warp-weighted loom. Warps are the downward hanging threads on a loom, and they are set up so that every other thread faces forward and the others are in the back. 2) A weft (horizontal thread) is then taken in between the forward and backward row of warps. 3) Before the weft is threaded through in the other direction, the position of the warps is changed with something called a heddle rod. This simple tool reverses the warps so that the row in the front is now in the rear, and visa versa. In this way the threads are woven in a cross stitch manner that holds them together and creates cloth. The cloth in turn is all kinds of things. Cloth is often sold to clothing manufacturers in rolls. One roll of cloth is about 11 meters in length.

Sometimes natural dies are used. Red is made with madder or kermes (an insect found in kermes oak); yellow with wild chamomile, saffron, vine leaves and the rinds of pomegranates; black from acorns; and blue from plants with indigo. Natural dyes produce richer and more natural colors. The depth of color can be controlled by the type of water — rain, river or spring — used. Plant dyes though are notoriously unpredictable. They are affected by weather conditions, soil and when they are harvested. They have mostly been replaced by chemical dyes.

Wool, Ancient History and Christianity

Adoration of shepherds by Rembrandt Famous reference to wool and sheep from the ancient world include Jason's quest for the Golden Fleece, Ulysses escaping from the Cyclops by clinging onto the underbelly of a ram, and Penelope's nightly unraveling of her weaving to keep suitors away until Ulysses returned. Salome's veils may have been wool and Cleopatra most likely used a wool carpet to smuggle herself in to see Caesar.╤

There are a number of references to wool-damaging pests in the ancient world. The Romans used bare-breasted virgins to beat away moths and beetles that ate their wool garments. Other cultures tried cow manure and garlic. Now we use moth balls. Proper washing is also supposed to be affective discouraging moths.

There are 300 references to sheep and lambs, more than any other animal, in the Old Testament, one the earliest documents that mentions sheep. Abraham, Moses and David tended a sheep at one time to make a living. Jacob gave Joseph a multicolored coat and Roman's drew lots to see who would get Jesus's cloak. Both garments were probably made of wool. During biblical times fleece was left out overnight in the desert to collect drinking water. In the morning dew was wrung out of it. ╤

The Pope, today, flies around in a plane called “Shepherd One” , and because the Old Testament forbids the mingling of wool and linen Jews sometimes have their clothing examine for this unkosher mix. St. Blaise, the patron saint of clothiers, is depicted in some Middle Ages churches practicing the eight processes used in wool making: sorting, washing, fulling, cropping, carding, weaving, teasing the nap, and pressing.╤

Wool in English History

Sheep played an important part in the development of the English economy and wool was England's first great industry. Land owners grew rich raising sheep. By the late Middle Ages the export of wool was the nations largest source of income. Their best customers were Flemish cloth merchants who later were imported to England to improve its own cloth making industry.[Source: Nina Hyde, National Geographic, May 1988 ╤]

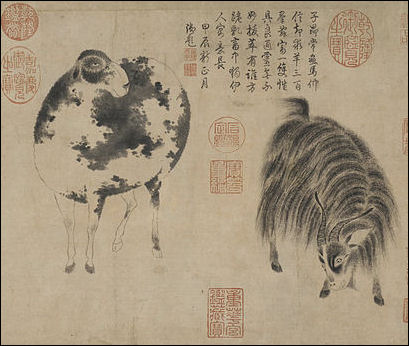

Sheep and Goat in Asian paintingIn medieval times the main purpose of English sheep was to fertilize fields. In the 13th century austere Cistercian monks became very rich by selling high quality wool three times the going price. Their product was so valuable the ransom to free Richard the Lionhearted, who was taken prisoner by the Austrians in the Third Crusade, was paid in Cistercian wool not money.╤

The Cistercians also invented futures trading. In their attempt to free themselves from the burden of the worldly life they left the responsibility of sheep rearing to their lay brothers. Not wanting to be bothered with annual piles of paper work the Cistercians signed contracts with promises to deliver their goods five to ten years in the future. Everything worked out fine unless the sheep died from disease or the supply of wool fell short of the wool promised by the contract. When this happened the monks were forced to buy wool at high prices to fill orders.╤

In the Middle Ages every country in Europe relied on England for wool. English royalty raised money from taxes and fees on the wool trade and ministers gained power by the granting of concessions to wool towns. In the nursery rhyme "Baa, Baa, Black Sheep," the first bag, the "One for my master," probably refers to the export tax on wool.╤

Wool churches like the one in Lavenham in East Anglia were financed by middlemen who became rich on a wool industry of weavers, spinners and fullers who did their work at home and depended on the middlemen’s financing and organizational skills to hold their operations together.╤

In the 16th century wool was so valuable and sheep were so easy to raise that farmland was converted in sheep pastures and people started to go hungry. "By the end of the 18th century," Nina Hyde wrote in National Geographic, "there were more than 300 British laws touching very aspect of the trade, from clipping the sheep to prohibiting the export of wool. In 1571 a man could be fined for not wearing a wool cap. By 1662 mourning clothes had to be made of English wool. And in 1667 a law required everyone to be buried in wool. Shepherds were buried with a tuft of wool on their chests: It explained to their Maker why they never got to church on Sunday.╤

Wool Processing

Traditionally processing wool involved eight steps: 1) sorting, 2) washing, 3) fulling, 4) cropping, 5) carding, 6) weaving, 7) teasing the nap, and 8) pressing. The common English last names Fuller and Weaver have their origins in the medieval wool processing trades. Combing and carding are two related techniques for preparing cotton, hair or wool fibres. With combing, fibres are passed through a series of straight, metal teeth in align the fibres parallel to one another so they can more easily be woven into yarn or fabric. Carding uses cards with numerous wire teeth that separate the fibres and spread them into a web (but not in parallel lines like with combed fires) and removes short or broken fibres as well as impurities. [Source: Leiden University]

Freshly sheared wool is sorted at a mill according to fineness, length and strength. In many parts of the world much of this work is still done by hand. Each type of wool product demands a different kind of wool. Tweeds, for example, need short thick fibers. Soft lamb’s wool is used for the best sweaters.

restored carding machine Raw wool is often dirty and full of impurities. In a process called scouring, the wool is cleaned in an alkali solution to remove the grease, which is often processed into lanolin. Soap and water baths get rid of perspiration.

Wool is "carded" in large machines consisting for revolving cylinders that straighten the fibers and comb them into filmy sheets. The carded wool is drawn out into a filmy strand in a processing called roving. The wool is then wound in a bobbin and spun into woolen yarn.

Woolen fabric is made from wool spun after the roving processes. Both woolen and worsted wools are spun by electric spinning machines that draw out the fibers and twist them into yarns made of two, three or four strands. Worsted wools go through more processing that lengthens the fibers by making them thinner and thinner.

After the yarns are woven into fabrics they saturated with hot water and put through rollers to shrink them. This process is called fulling. Strands are cut and evened out with a machine that operates like a lawn mover. The fabric is then dry-steamed and pressed between hot plates and ready for market.

Wool Technology

In the old days buyers relied on their eyes and noses and fingers to judge the quality of wool. Now wool-testing authorities objectively test wools on the basis of fiber diameter, vegetable-matter content, and clean-wool yield. Today over 98 percent of the wool sold in auctions has been tested in this manner. It has been around 40 years since wool was judged by sight and touch.

Researchers at a sheep station 70 miles from Mount Cook in New Zealand are attempting to produce wools that have many of the attributes of synthetic fibers by breeding sheep with uniform superfine wool, using computerized objective measurement of the highly inheritable factors such as wool diameter and fleece weight. and using this information to guide sheep into carefully thought out breeding programs. In the 1980s, the University of Western Australian spent $1 million to develop a robotic sheep shearing machine. Built into the machine is a devise that can retract the blade in increments of five thousandths of an inch, enough to allow it to adjust for the animals breathing. The 1982 version of the machine could sheer an animal in three minutes about the same as a man. The ones made today are much faster.♬

To reduce shearing costs researchers have now experimenting with a compound made from the glands of mice which weaken the fleece and allows it to be plucked by hand. In Edinburgh A dentist has worked for years to combat the problem of sheep losing their teeth by trying to develop splints to support loose sheep teeth.. ╤

Wool Markets

handshorn woolOnce the world's dominate cloth-making fiber, wool now only accounts for five percent of world textile fiber market. The Soviet Union used to be far away the world's largest consumer of wool. With a conservative attitude about synthetics, a cold climate and a considerable amount of wool used in military uniforms, it consumed more wool than the United States and Japan, the No. 2 and No. 3 consumers, combined.╤

Wool prices fluctuate a great deal and over past few decades have declined considerably as a result of competition from cheaper, lightweight cotton and synthetics, and increased demand by consumers for sports clothes and casual clothes that tend to be made from cotton and synthetics rather than wool. .

Competition from synthetics has pushed the price of wool down to a record low of 429.3 cents per kilogram in 1993. After prices rose through the 1990s they collapsed again from an average from 702 cents per kilogram in first half of 1997-98 to about 484 cents in October, 1999 in part because of the Asian financial crisis.

Many of the sheep raised in Australia and New Zealanders are not produced for wool but are produced for meat in Muslim countries where people don't eat pork and beef is prohibitively expensive. At ports in Australia sheep are slaughtered facing Mecca using the halal method before being shipped off to the Persian Gulf in converted oil tankers that are seven stories high and can carry 115,000 sheep. It takes two days just to load one of these ships.

The fortunes of the economies of countries like Australian and New Zealand often used to rise and fall with the world price of wool. To help station owner ride out these fluctuations the Australian government used to buy owner's wool at an inflated prices if wool dropped below a certain level. These days these tactics are no longer as common they once were. Countries that were once depended on wool have tried to diversify so they were are no so reliant on it and many former wool ranchers have found other ways to make a living.

In recent years wool prices have fallen as consumers have switched to cotton and synthetics

World’s Top Wool Exporting Countries

Most wool is produced in the Southern Hemisphere and shipped to the Northern Hemisphere. Australia leads the world in production followed bySouth Africa and New Zealand. China and India are large importers of wool.

Wool in Newcastle World’s Top Exporters of Wool, Greasy (2020): 1) Australia: 242188 tonnes; 2) South Africa: 49263 tonnes; 3) New Zealand: 29731 tonnes; 4) Lesotho: 9434 tonnes; 5) Spain: 7499 tonnes; 6) Romania: 6947 tonnes; 7) United Kingdom: 6548 tonnes; 8) Argentina: 6096 tonnes; 9) Brazil: 5155 tonnes; 10) Syria: 5047 tonnes; 11) Italy: 4984 tonnes; 12) Uruguay: 3825 tonnes; 13) Saudi Arabia: 3792 tonnes; 14) Ireland: 3449 tonnes; 15) France: 3220 tonnes; 16) Norway: 2766 tonnes; 17) Peru: 2446 tonnes; 18) United States: 2395 tonnes; 19) Tunisia: 2394 tonnes; 20) Belgium: 2040 tonnes [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org]

World’s Top Exporters (in value terms) of Wool, Greasy (2020): 1) Australia: US$1444231,000; 2) South Africa: US$254622,000; 4) New Zealand: US$103363,000; 4) Lesotho: US$37823,000; 5) Argentina: US$24368,000; 6) Uruguay: US$20762,000; 7) Brazil: US$15013,000; 8) Spain: US$14538,000; 9) United Kingdom: US$9959,000; 10) Libya: US$7664,000; 11) United States: US$7428,000; 12) Chile: US$5445,000; 13) Peru: US$5378,000; 14) France: US$3853,000; 15) Syria: US$3401,000; 16) Germany: US$3113,000; 17) Italy: US$3046,000; 18) Russia: US$3018,000; 19) Romania: US$2850,000; 20) Ireland: US$2737,000

World’s Top Exporters of Wool, Degreased (2020): 1) New Zealand: 59607 tonnes; 2) United Kingdom: 14404 tonnes; 3) Syria: 11396 tonnes; 4) Turkey: 10412 tonnes; 5) Australia: 9852 tonnes; 6) Mongolia: 7546 tonnes; 7) China: 4839 tonnes; 8) Belgium: 4707 tonnes; 9) Uruguay: 3211 tonnes; 10) Turkmenistan: 2279 tonnes; 11) Uzbekistan: 2109 tonnes; 12) Germany: 1881 tonnes; 13) Algeria: 1759 tonnes; 14) Russia: 1642 tonnes; 15) United Arab Emirates: 1592 tonnes; 16) Tunisia: 1582 tonnes; 17) Saudi Arabia: 1165 tonnes; 18) Spain: 1052 tonnes; 19) Portugal: 908 tonnes; 20) Libya: 670 tonnes

World’s Top Exporters (in value terms) of Wool, Degreased (2020): 1) New Zealand: US$137880,000; 2) Australia: US$83490,000; 3) United Kingdom: US$34281,000; 4) China: US$21764,000; 5) Uruguay: US$18990,000; 6) Belgium: US$14980,000; 7) Turkey: US$13928,000; 8) Germany: US$8949,000; 9) Syria: US$8372,000; 10) United Arab Emirates: US$7034,000; 11) Mongolia: US$6959,000; 12) Russia: US$4480,000; 13) South Africa: US$4315,000; 14) Italy: US$4286,000; 15) Malaysia: US$2304,000; 16) Belarus: US$2171,000; 17) Spain: US$2157,000; 18) Portugal: US$1874,000; 19) France: US$1806,000; 20) Turkmenistan: US$1520,000

World’s Top Wool Importing Countries

World’s Top Importers of Wool, Greasy (2020): 1) China: 187012 tonnes; 2) India: 34346 tonnes; 3) Czechia: 24618 tonnes; 4) Uruguay: 10947 tonnes; 5) South Africa: 9449 tonnes; 6) Italy: 8778 tonnes; 7) United Kingdom: 8075 tonnes; 8) Turkey: 6687 tonnes; 9) Bulgaria: 6592 tonnes; 10) Belgium: 4995 tonnes; 11) Egypt: 2966 tonnes; 12) Belarus: 2869 tonnes; 13) Nepal: 2000 tonnes; 14) Portugal: 1990 tonnes; 15) Spain: 1408 tonnes; 16) Germany: 794 tonnes; 17) United States: 674 tonnes; 18) Malaysia: 667 tonnes; 19) France: 578 tonnes; 20) Republic of Moldova: 569 tonnes [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org]

wool display World’s Top Importers (in value terms) of Wool, Greasy (2020): 1) China: US$1552959,000; 2) Czechia: US$112731,000; 3) India: US$90841,000; 4) Italy: US$85962,000; 5) South Africa: US$37185,000; 6) Bulgaria: US$36199,000; 7) Uruguay: US$28055,000; 8) Egypt: US$22794,000; 9) United Kingdom: US$7184,000; 10) Nepal: US$5000,000; 11) Mauritius: US$4021,000; 12) Belgium: US$3966,000; 13) Taiwan: US$3638,000; 14) Germany: US$3516,000; 15) Belarus: US$3253,000; 16) United States: US$3171,000; 17) Turkey: US$2916,000; 18) Malaysia: US$2551,000; 19) Spain: US$1756,000; 20) Portugal: US$1682,000

World’s Top Importers of Wool, Degreased (2020): 1) India: 44301 tonnes; 2) China: 34450 tonnes; 3) United Kingdom: 13352 tonnes; 4) Lithuania: 8882 tonnes; 5) Italy: 6597 tonnes; 6) Germany: 5468 tonnes; 7) South Korea: 4692 tonnes; 8) Russia: 4133 tonnes; 9) Nepal: 3546 tonnes; 10) Japan: 2921 tonnes; 11) Belgium: 2295 tonnes; 12) United States: 2261 tonnes; 13) Portugal: 2198 tonnes; 14) Thailand: 2120 tonnes; 15) Poland: 1974 tonnes; 16) Australia: 1939 tonnes; 17) Iran: 1880 tonnes; 18) United Arab Emirates: 1610 tonnes; 19) Turkey: 1315 tonnes; 20) Belarus: 1049 tonnes

World’s Top Importers (in value terms) of Wool, Degreased (2020): 1) China: US$70252,000; 2) India: US$55384,000; 3) South Korea: US$41418,000; 4) United Kingdom: US$31482,000; 5) Italy: US$29056,000; 6) Lithuania: US$24604,000; 7) Germany: US$19910,000; 8) Thailand: US$15751,000; 9) Japan: US$15035,000; 10) United States: US$10292,000; 11) Iran: US$10171,000; 12) Nepal: US$8246,000; 13) Taiwan: US$7740,000; 14) United Arab Emirates: US$6983,000; 15) Turkey: US$6052,000; 16) Belgium: US$4896,000; 17) Belarus: US$4896,000; 18) Australia: US$4875,000; 19) Portugal: US$4577,000; 20) Poland: US$4256,000

Wool Grease and Sheep Skin Producers and Exporters

World’s Top Exporters of Wool Grease including Lanolin (2020): 1) China: 10906 tonnes; 2) United Kingdom: 4647 tonnes; 3) United States: 2544 tonnes; 4) Belgium: 1805 tonnes; 5) Uruguay: 1647 tonnes; 6) Japan: 1504 tonnes; 7) Germany: 1045 tonnes; 8) Czechia: 946 tonnes; 9) Australia: 642 tonnes; 10) India: 458 tonnes; 11) Italy: 453 tonnes; 12) Argentina: 395 tonnes; 13) Netherlands: 339 tonnes; 14) Bulgaria: 299 tonnes; 15) Brazil: 283 tonnes; 16) Chile: 245 tonnes; 17) Egypt: 130 tonnes; 18) France: 80 tonnes; 19) Taiwan: 74 tonnes; 20) Singapore: 62 tonnes [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org]

World’s Top Exporters (in value terms) of Wool Grease including Lanolin (2020): 1) China: US$43682,000; 3) United Kingdom: US$35535,000; 3) Japan: US$18877,000; 4) Belgium: US$18418,000; 5) Netherlands: US$15420,000; 6) Germany: US$12105,000; 7) United States: US$8795,000; 8) Uruguay: US$6104,000; 9) Czechia: US$3674,000; 10) Australia: US$2969,000; 11) India: US$2481,000; 12) Brazil: US$2407,000; 13) Italy: US$2029,000; 14) Argentina: US$1209,000; 15) Bulgaria: US$1052,000; 16) France: US$812,000; 17) Chile: US$695,000; 18) Taiwan: US$435,000; 19) Turkey: US$384,000; 20) Israel: US$381,000

World’s Top Producers of Fresh Sheep Skins (2020): 1) China: 616626 tonnes; 2) Australia: 151738 tonnes; 3) New Zealand: 83440 tonnes; 4) United Kingdom: 63843 tonnes; 5) Mongolia: 61114 tonnes; 6) Pakistan: 53680 tonnes; 7) Algeria: 52826 tonnes; 8) Iran: 44914 tonnes; 9) India: 42633 tonnes; 10) Sudan: 39901 tonnes; 11) Ethiopia: 33061 tonnes; 12) Chad: 31822 tonnes; 13) Nigeria: 27416 tonnes; 14) Russia: 25854 tonnes; 15) Morocco: 25517 tonnes; 16) Syria: 24629 tonnes; 17) South Africa: 23901 tonnes; 18) Kazakhstan: 19946 tonnes; 19) Uzbekistan: 19727 tonnes; 20) Brazil: 18135 tonnes [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org]

Image Sources: Wikimedia Commons

Text Sources: Mostly National Geographic articles. Also Time, Newsweek, New York Times, Washington Post, Los Angeles Times, Wikipedia, The Independent, Times of London, The New Yorker, Time, Newsweek, Reuters, AP, AFP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated April 2022