RUBBER

latex straight from the tree Rubber is rubbery material made from latex, a milky liquid that drips out of a rainforest tree like the sap used to make maple syrup. It is used in making auto tires, industrial conveyor belts, condoms, surgical gloves, sporting equipment, shoes, sportswear and a wide range of goods for bicycles, cars, motorcycles, machinery, and an additive for other chemicals and other products.

Charles C. Mann wrote in National Geographic: Thick white latex drips into buckets. The goo is coagulated into solids that are pressed into sheets and transported to factories, where they are processed into O-rings, belts, gaskets, insulation, and tires — lots and lots of tires. About three-quarters of the world’s rubber harvest goes to make automobile, truck, and airplane tires — almost two billion a year. Because rubber is so common, so unobtrusive, so dull, it may not seem worth a second glance. This would be a mistake. Rubber has played a largely hidden role in global political and environmental history for more than 150 years. [Source: Charles C. Mann, National Geographic, December 12, 2015]

“To the extent that most people think about rubber at all, they likely picture a product made from synthetic chemicals. In fact, more than 40 percent of the world’s rubber comes from trees, almost all of them H. brasiliensis. Compared with natural rubber, synthetic rubber is usually cheaper to produce but is weaker, less flexible, and less able to withstand vibration. For things that absolutely cannot fail, from condoms to surgeon’s gloves to airplane tires, natural rubber has long been the top choice.

Rubber is an essential ingredient for industry, particularly automobiles. Charles C. Mann wrote in National Geographic: You need three raw materials: iron, to make steel for machinery; fossil fuels, to power that machinery; and rubber, to connect and protect all the moving parts. Try running an automobile without a fan belt or a radiator hose; very bad things will happen within a minute. Want to send coolant around an engine using a rigid metal tube instead of a flexible rubber hose? Good luck keeping it from vibrating to pieces. Having enough steel and coal to make and drive industrial machinery means nothing if the engines fry because you can’t cool them.

Because aircraft tires must not fail, airplane tires are usually made with natural rubber, which is stronger, more flexible, and better able to withstand vibration than synthetic rubber. Tubes of extruded latex are cut into rubber bands at the Keener Rubber Company near Akron, Ohio. The factory is a reminder of the days when Akron was the “rubber capital of the world” — as it once housed the four biggest tire firms in the world. As global car sales have soared, the demand for tires and other rubber products has transformed Southeast Asia’s landscape. New plantations of rubber trees are lifting some out of poverty — but may also spark an ecological disaster.

See Separate Article: HISTORY OF RUBBER factsanddetails.com

World’s Top Rubber Producing Countries

World’s Top Producers of Natural Rubber (2020): 1) Thailand: 4703171 tonnes; 2) Indonesia: 3366415 tonnes; 3) Vietnam: 1226096 tonnes; 4) India: 962807 tonnes; 5) Côte d'Ivoire: 936061 tonnes; 6) China: 687600 tonnes; 7) Malaysia: 514702 tonnes; 8) Guatemala: 436409 tonnes; 9) Philippines: 422407 tonnes; 10) Cambodia: 349300 tonnes; 11) Myanmar: 259500 tonnes; 12) Brazil: 225622 tonnes; 13) Laos: 154200 tonnes; 14) Nigeria: 148435 tonnes; 15) Mexico: 92711 tonnes; 16) Sri Lanka: 78204 tonnes; 17) Liberia: 64878 tonnes; 18) Ghana: 50400 tonnes; 19) Cameroon: 47100 tonnes; 20) Gabon: 23941 tonnes ; [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org. A tonne (or metric ton) is a metric unit of mass equivalent to 1,000 kilograms (kgs) or 2,204.6 pounds (lbs). A ton is an imperial unit of mass equivalent to 1,016.047 kg or 2,240 lbs.]

World’s Top Producers (in terms of value) of Natural Rubber (2019): 1) Thailand: Int.$6083238,000 ; 2) Indonesia: Int.$4334705,000 ; 3) Vietnam: Int.$1489600,000 ; 4) India: Int.$1258646,000 ; 5) China: Int.$1055665,000 ; 6) Côte d'Ivoire: Int.$835442,000 ; 7) Malaysia: Int.$804189,000 ; 8) Philippines: Int.$542564,000 ; 9) Guatemala: Int.$440538,000 ; 10) Myanmar: Int.$333002,000 ; 11) Brazil: Int.$273229,000 ; 12) Cambodia: Int.$219577,000 ; 13) Nigeria: Int.$188144,000 ; 14) Mexico: Int.$100524,000 ; 15) Sri Lanka: Int.$93952,000 ; 16) Cameroon: Int.$63499,000 ; 17) Liberia: Int.$52802,000 ; 18) Ghana: Int.$38335,000 ; 19) Gabon: Int.$34799,000 ; 20) Bangladesh: Int.$28657,000 ; [An international dollar (Int.$) buys a comparable amount of goods in the cited country that a U.S. dollar would buy in the United States.]

Top Rubber Producing Countries in 2008: (Production, $1000; Production, metric tons,, FAO): 1) Thailand, 1698667 , 3166910; 2) Indonesia, 1567233 , 2921872; 3) Malaysia, 575213 , 1072400; 4) India, 439295 , 819000; 5) Viet Nam, 353796 , 659600; 6) China, 293861 , 547861; 7) Philippines, 220475 , 411044; 8) Côte d'Ivoire, 101124 , 188532; 9) Nigeria, 76702 , 143000; 10) Sri Lanka, 69321 , 129240; 11) Brazil, 64851 , 120905; 12) Liberia, 43446 , 81000; 13) Guatemala, 37546 , 70000; 14) Cameroon, 27891 , 52000; 15) Myanmar, 24137 , 45000; 16) Cambodia, 16990 , 31676; 17) Mexico, 14862 , 27709; 18) Guinea, 7455 , 13900; 19) Ecuador, 7375 , 13750; 20) Ghana, 7241 , 13500;

Tapping Rubber

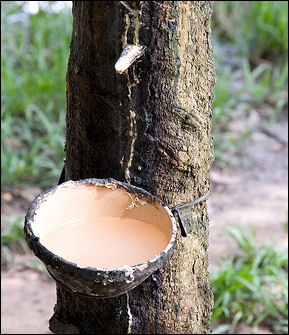

Latex being collected from

a tapped rubber tree When a rubber tree is about six years old and six inches in diameter it is ready to be tapped for latex, which lies in tubes that spiral from the ground to the top of the trunk in the inner bark of the tree. The latex is harvested by slicing a groove into the bark of the tree at a depth of a quarter inch with a hooked knife and peeling back the bark. The groove is cut diagonally or in a semicircle across the trunk, deep enough to penetrate the outer bark and reach the inner bark, where the latex lies.

The latex drips into cups from the incisions in the bark. A typical tree produces a few ounces’ worth of rubber a day. It typically takes a month’s worth of latex from four trees to make just one tire. The latex comes out watery and milky white. A cup is set underneath the groove to collect the latex which initially flows out like blood, then slowly clots blood when exposed to air and slows to a dribble and finally stops after about three or four hours.

Because rubber sap flows best at night, tappers use headlamps to light the trees while they work in the dark. In the old days Brazilian tappers usually worked early in the morning, often before sunrise, with gaslight lamps on their heads that produce a small flame fueled by a gas bottle in the tappers backpack. It is a delicate job. The bark has to be gouged just enough to start the latex flowing but not enough that the tree is damaged.

Tappers in the rainforest often leave the cup in place for at least a couple days before they collect the latex. Tappers on plantations often collect the latex in the late morning and carry it away in pales every other day and often add of few small drop of ammonia or another chemical to the cups to keep the rubber from coagulating.

Amazon Rubber Tappers

In the 1980s and 90s it was is estimated that there were between 70,000 and 300,000 rubber tappers, or “seringueiros”, working in the Amazon forest. The estimates were so imprecise because it was hard to do a census of men who primarily wandered through the rain forests alone. [Source: Michael Parfit, Smithsonian magazine, November 1989]

Rubber tappers often live almost entirely in the forest, carrying guns for protection against Indians and animals. During the rains they sometimes harvest Brazil nuts. In the 1980s they were organized into an environmental group intent on saving the Amazon forest.

Many seringueiros in the 1980s and 90s were indentured into a kind of debt slavery by the land owners who charge them rent to tap their trees and provide them with supplies. The money they are payed for the latex they tap is never enough to pay for the supplies. "The life of a seringueiro," one of them said, "is the most suffocating life you can have. He fights and fights and has nothing. His hands are full of smoke.

Traditionally rubber tappers have been a lonely group. The break narrow paths in the jungles and taps the trees and leave cups to collect the dripping latex. After a week or so they return to the trees they have tapped and collect the latex. Indians used to frustrate the tappers by stealing their cups and the tappers used to get even by firing shots to scare them off. [Source: Harald Scultz, National Geographic, May 1964]

In the 1980s some seringeiros vanished into the forest for months at times, fighting off disease Indians, insects and poisonous snakes. Some of them used kerosene lamps to gather latex before dawn and after dusk and worked all day, seven days a week for about $80 a month. Latex at that time sold for about 60 cents a kilograms (25 cents a pound) and efficient tappers could collect about 500 kilograms (1,100 pounds) of latex during the dry season. In the rainy season they supplement their income by gathering Brazil nuts. Many of them live in shacks in settlements with no schools or any social life to speak of. The nearest medical help is several hours away by boat.

Even after all this the government artificially propped up the price of rubber to help the seringeiros earn the little they did. Latex is grown much more efficiently and profitably on plantations in Southeast Asian countries, and their latex is much better quality than wild latex from the Amazon, which is filled with impurities.

See Chico Mendes Under COMBATING DEFORESTATION AND EFFORTS TO SAVE THE RAINFOREST factsanddetails.com

Leaf Blight

The South American leaf blight has ruined every effort to establish rubber plantations in Amazonia. If the disease were to catch hold in Southeast Asia it could be cause the biggest supply chain tie up of all time and among other things slam the brakes on the automobile industry.

Charles C. Mann wrote in National Geographic: “Microcyclus ulei, as biologists call it, looks at rubber trees the way ant armies look at frogs: as lunch. The fungus “doesn’t kill trees straight out,” historian Greg Grandin explains in his book Fordlandia. Instead its spores tunnel into leaves, consuming their nutrients until they fall off. When the leaves regrow, the fungus attacks again; the trees, Grandin writes, “grow successively weaker, either producing dwarf shoots or dying back altogether.” [Source: Charles C. Mann, National Geographic, December 12, 2015]

“The battle is silent, protracted, and for the tree, almost invariably fatal. In the wild Microcyclus ulei spores can’t spread easily from one rubber tree to another because the trees are widely dispersed in the forest. On a plantation, trees are close to one another, like dishes at a buffet, letting the fungus hop easily between them, one plate to the next.

Plantation Rubber and Processing

Tapping a rubber tree

in Thailand Much of the world's rubber today is produced on large rubber plantations that spread as far as the eye can see, primarily in Malaysia, Indonesia and Thailand. A single tree can be harvested for 25 years or more, and trees that have tapped for this long are scared by parallel lines of grooves. Trees reach peak reproduction at around age 12. Some trees produce until they are 70 years old but have much lower yields than younger trees.

After the initial groove is made, thin shaving cuts about 1/16th of an inch deep are taken from the groove when it is tapped. The groove is lowered by about an inch a year. When it is within a foot of the ground, the other side of the tree is tapped. After about five years the bark on the other side is renewed and taping can resumed there. To increase the productivity of rubber trees farmers shoot them full of hormones which causes the latex not clot.

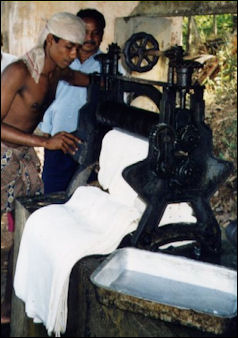

High grade trees yield about 30 pounds of rubber a year. After the latex is collected from the trees it is poured into pans where rubber is coagulated from the latex by adding formic acid. One pound of rubber is extracted from every three pounds of latex.

The new rubber is squeezed through a wringer to get out excess water and formed into rubber "biscuits," about the size of a hockey puck. These are dried in the sun for several weeks and then cured in a big smoky fire for several days and then pressed into large bales. On large plantation these processes are in processing plants using machine invented in 1963 that removes the waters, dries and bales the rubber in one continuous operation in less than ten minutes.

Baled rubber is sent to factories to be vulcanized and undergo other kinds of processing. Latex from the rubber tree is gooey when hot and brittle when cold. When mixed with sulphur — vulcanization — it becomes smooth and pliable regardless of whether it is hot or cold. The more sulfur the stiffer the rubber. Hard rubber is 30 to 50 percent sulfur.

Rubber Market

Thailand, Malaysia and Indonesia are the world’s largest rubber producers. In the mid 2000s Thailand was the world’s largest rubber exporter. It produced 69,000 tons and supplied 38 percent of the world’s rubber in 2004. Much of the Thailand’s rubber production is bought by China and tire makers. In 2004, Thailand exported 1.5 million tons of rubber, worth $2.5 billion, to China. In 2005 sheets of ribbed smoked rubber rose 57 percent to $1.73 a kilogram on the back of continued strong demand from China.

In the 2000s, tire companies consumed about 70 percent of the world’s natural rubber. China is the largest rubber user as it is now a large vehicle and tire producer and consumer. On the commodities markets rubber sold for about $3 to $4 a kilogram in the 2000s.

The price of rubber is often linked with the price of oil, When the price of oil goes up so too does rubber because when the cost of making petroleum-based synthetic rubber goes up many tire and rubber producers buy more rubber as a cheaper alternative, driving up demand for rubber and the price. High oil prices in the mid-2000s and late-2000s increased demand for natural rubber.

In 2004, Japanese researchers reported they had made rubber from edible wild mushrooms and that the rubber was superior to regular rubber in that it lacked a protein that cause allergies.

Rubber in Southeast Asia

Charles C. Mann wrote in National Geographic: rubber today is grown almost exclusively in Southeast Asia, because the region has a unique combination of suitable climate and infrastructure. Despite all the ups and downs in the global economy, the demand for tires continues to grow, which has created something akin to a gold rush in Southeast Asia. For millions of people in this poor part of the world, the rubber boom has helped bring prosperity... Rubber has helped end the region’s isolation. Brand-new “rubber highways” — the last finished in 2013 — now connect previously remote plantations in Southeast Asia to tire factories in northern China. [Source: Charles C. Mann, National Geographic, December 12, 2015]

“To grow that extra rubber, Southeast Asian farmers have cleared about 18,000 square miles, an area about the size of Massachusetts and Vermont put together. And that figure doesn’t include the forest logged for new processing facilities, the new homes built in the forest for new rubber workers, or the roads cut to reach the new plantations.

“All that production — combined with a decline in demand — has made rubber prices fall in the past few years, but nobody expects the growth to stop. The boom means that a random visitor like me can drive around northern Laos at night and see fires in the hills — set by families burning patches of forest to make room for new plantings. It means teenage Thai boys drive by on motorcycles groaning beneath a half dozen garbage bags full of homemade balls of coagulated latex. It means entire farming villages that get up at two in the morning to tap rubber trees, because latex flows best before dawn.

World’s Top Rubber Exporting Countries

World’s Top Exporters of Dry Natural Rubber (2020): 1) Indonesia: 2274882 tonnes; 2) Thailand: 1506110 tonnes; 3) Cote d’Ivoire: 1078237 tonnes; 4) Malaysia: 544907 tonnes; 5) Cambodia: 462145 tonnes; 6) Vietnam: 382800 tonnes; 7) Laos: 234181 tonnes; 8) Philippines: 144608 tonnes; 9) Myanmar: 123847 tonnes; 10) Ghana: 80490 tonnes; 11) Belgium: 75951 tonnes; 12) Liberia: 74195 tonnes; 13) Singapore: 66557 tonnes; 14) Guatemala: 60779 tonnes; 15) Luxembourg: 47565 tonnes; 16) France: 42560 tonnes; 17) Germany: 40533 tonnes; 18) Nigeria: 33003 tonnes; 19) Gabon: 29762 tonnes; 20) Netherlands: 19847 tonnes ; [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org]

World’s Top Exporters (in value terms) of Dry Natural Rubber (2020): 1) Indonesia: US$3003686,000; 2) Thailand: US$2249784,000; 3) Cote d’Ivoire: US$1123391,000; 4) Malaysia: US$741314,000; 5) Vietnam: US$581547,000; 6) Cambodia: US$408234,000; 7) Laos: US$292030,000; 8) Myanmar: US$209727,000; 9) Belgium: US$105588,000; 10) Liberia: US$102835,000; 11) Philippines: US$97231,000; 12) Singapore: US$89925,000; 13) Ghana: US$88628,000; 14) France: US$84453,000; 15) Guatemala: US$80963,000; 16) Luxembourg: US$78691,000; 17) Germany: US$69514,000; 18) United States: US$43697,000; 19) Nigeria: US$41943,000; 20) Gabon: US$36467,000

World’s Top Exporters of Natural Rubber (2020): 1) Thailand: 1147585 tonnes; 2) Vietnam: 191081 tonnes; 3) Guatemala: 60126 tonnes; 4) Laos: 40366 tonnes; 5) Belgium: 21819 tonnes; 6) Malaysia: 19644 tonnes; 7) Netherlands: 17342 tonnes; 8) Cameroon: 9334 tonnes; 9) Myanmar: 8170 tonnes; 10) India: 6550 tonnes; 11) Germany: 6487 tonnes; 12) Indonesia: 5208 tonnes; 13) Côte d'Ivoire: 4877 tonnes; 14) Democratic Republic of the Congo: 3584 tonnes; 15) United States: 3518 tonnes; 16) Sri Lanka: 3435 tonnes; 17) United Kingdom: 1316 tonnes; 18) France: 1038 tonnes; 19) Italy: 982 tonnes; 20) Ghana: 927 tonnes

World’s Top Exporters (in value terms) of Natural Rubber (2020): 1) Thailand: US$1275269,000; 2) Vietnam: US$204157,000; 3) Guatemala: US$65340,000; 4) Malaysia: US$43247,000; 5) Laos: US$38635,000; 6) Netherlands: US$32767,000; 7) Belgium: US$24805,000; 8) Cameroon: US$10208,000; 9) United States: US$10044,000; 10) Myanmar: US$9935,000; 11) Germany: US$9109,000; 12) India: US$8887,000; 13) Indonesia: US$6559,000; 14) Cote d’Ivoire: US$5769,000; 15) Sri Lanka: US$4633,000; 16) United Kingdom: US$3578,000; 17) Italy: US$1973,000; 18) France: US$1943,000; 19) Sweden: US$1753,000; 20) Mexico: US$1425,000

The worlds top exporters of rubber in 1988 were: 1) Malaysia, 2) Indonesia, 3) Thailand, 4) the U.S., 5) France, 6) W. Germany, 7) Japan, 8) the Netherlands, 9) U.S.S.R. and 10) the UK. The worlds top producers of rubber in 1988 were: 1) USSR, 2) the U.S., 3) Malaysia, 4) Japan, 5) Indonesia, 6) Thailand, 7) France, 8) W. Germany, 9) the UK, 10) Brazil.

World’s Top Rubber Importing Countries

rubber production in Goa World’s Top Importers of Dry Natural Rubber (2020): 1) China: 1728441 tonnes; 2) Malaysia: 873582 tonnes; 3) United States: 767174 tonnes; 4) Vietnam: 604712 tonnes; 5) Japan: 554382 tonnes; 6) India: 372625 tonnes; 7) South Korea: 286818 tonnes; 8) Germany: 215170 tonnes; 9) Turkey: 188424 tonnes; 10) Spain: 157084 tonnes; 11) Brazil: 141173 tonnes; 12) Russia: 107662 tonnes; 13) France: 104846 tonnes; 14) Canada: 103815 tonnes; 15) Poland: 99495 tonnes; 16) Italy: 98047 tonnes; 17) Taiwan: 96022 tonnes; 18) Singapore: 87524 tonnes; 19) Belgium: 80011 tonnes; 20) Luxembourg: 74998 tonnes ; [Source: FAOSTAT, Food and Agriculture Organization (U.N.), fao.org]

World’s Top Importers (in value terms) of Dry Natural Rubber (2020): 1) China: US$2442258,000; 2) United States: US$1304522,000; 3) Japan: US$831787,000; 4) Malaysia: US$821024,000; 5) Vietnam: US$609073,000; 6) India: US$538868,000; 7) South Korea: US$405144,000; 8) Germany: US$334379,000; 9) Turkey: US$281510,000; 10) Spain: US$255538,000; 11) Brazil: US$222930,000; 12) Liberia: US$210000,000; 13) France: US$170159,000; 14) Canada: US$169677,000; 15) Russia: US$168418,000; 16) Italy: US$167011,000; 17) Poland: US$152224,000; 18) Taiwan: US$147520,000; 19) Belgium: US$123957,000; 20) Singapore: US$117791,000

World’s Top Importers of Natural Rubber (2020): 1) China: 570253 tonnes; 2) Malaysia: 348311 tonnes; 3) Mexico: 51269 tonnes; 4) United States: 36756 tonnes; 5) Netherlands: 33178 tonnes; 6) Brazil: 31470 tonnes; 7) Belgium: 30880 tonnes; 8) Vietnam: 27228 tonnes; 9) Indonesia: 26485 tonnes; 10) Turkey: 21538 tonnes; 11) South Korea: 20864 tonnes; 12) Sri Lanka: 17640 tonnes; 13) Italy: 16917 tonnes; 14) Iran: 13337 tonnes; 15) Germany: 12085 tonnes; 16) United Kingdom: 11871 tonnes; 17) Pakistan: 11386 tonnes; 18) Spain: 9588 tonnes; 19) Colombia: 8766 tonnes; 20) Russia: 7420 tonnes

World’s Top Importers (in value terms) of Natural Rubber (2020): 1) Malaysia: US$639176,000; 2) China: US$633561,000; 3) Mexico: US$62679,000; 4) United States: US$51765,000; 5) Netherlands: US$40173,000; 6) Brazil: US$37711,000; 7) Belgium: US$36258,000; 8) Vietnam: US$34442,000; 9) Indonesia: US$30137,000; 10) Turkey: US$26067,000; 11) South Korea: US$24786,000; 12) Italy: US$23489,000; 13) Sri Lanka: US$20823,000; 14) United Kingdom: US$20750,000; 15) Pakistan: US$18114,000; 16) Iran: US$17669,000; 17) Germany: US$15853,000; 18) Spain: US$11919,000; 19) Colombia: US$10698,000; 20) Russia: US$9571,000

Environmental Impact of Rubber Agriculture

In Southeast Asia, farmers clear forest to grow rubber on land opened by new roads connecting plantations with tire factories in China. Rubber trees need lots of water and environmentalist fear that so much rubber will degrade ecosystems across Southeast Asia. Charles C. Mann wrote in National Geographic: Rubber farmers in Southeast Asia “have set off what Jefferson Fox of the East-West Center in Hawaii calls “one of the biggest, fastest ecological transformations in human history.” In China, Vietnam, Laos, Thailand, Cambodia, and Myanmar rubber farmers have cut or burned down forests and planted row after row after row of H. brasiliensis. In the process, they are converting one of the world’s most diverse ecosystems into a monoculture as uniform as a Kansas wheat field, potentially threatening the basic ecological functions of an area inhabited by tens of millions of people. “Monocultures are intensely productive — and intensely vulnerable. [Source: Charles C. Mann, National Geographic, December 12, 2015]

To grow that extra rubber, Southeast Asian farmers have cleared about 18,000 square miles, an area about the size of Massachusetts and Vermont put together. And that figure doesn’t include the forest logged for new processing facilities, the new homes built in the forest for new rubber workers, or the roads cut to reach the new plantations.

The ecological threat posed by the rubber boom goes beyond the loss of biodiversity. Rubber trees are terribly susceptible to blight. “The potential of an economic disaster increases with every transcontinental flight landing in Southeast Asia,” two researchers at Florida A&M University warned in 2012. A UN Food and Agriculture Organization report the previous year recommended that all air passengers bound for Southeast Asia who have been in South America’s blight zone within the previous three weeks should be inspected. No such program has been enacted. Although scientists in Brazil have found and begun testing resistant varieties of rubber trees, no Asian breeding program for blight resistance has been established. In four visits to Southeast Asia I didn’t encounter a single rubber farmer who was considering resistant varieties.

“Even ecologists have devoted little attention to the threat. Instead they focus on “more immediate issues,” says Xu Jianchu, of China’s Kunming Institute of Botany, about 200 miles northeast of Xishuangbanna. Rubber tappers, working at night, fear encountering snakes in the dark, so they drench the hills with herbicides to wipe out snake-hiding ground cover. Species that depend on the destroyed plants quickly succumb too — a further loss of biodiversity. Rain erodes the exposed earth, threatening the soil.

“Perhaps most serious, rubber trees consume a lot of water in the process of making latex. Producing tires is like taking groundwater from the hills and putting it on trucks for export. As a consequence, Xu says, highland wells and rivers are drying up. The industry response has been that “people can get water in plastic bottles,” he says, with a grimace. Soon rubber will cover most of Southeast Asia. The problems will spread from China to much of Southeast Asia. “Unless governments step in, it will not stop.”

Ecologically-Friendly Rubber Agriculture in China

Nabanhe National Nature Reserve in Yunnan’s Xishuangbanna region of China is an innovative park that tries to protect the forest while allowing its inhabitants to tap rubber. Mann wrote: The landscape switched back and forth between plantation and wildland in a way that reminded me, to my surprise, of the patchwork of fields and forest around my New England home. We were going to the reserve because the reserve’s research director, Liu Feng, and Gerhard Langenberger, an agroecologist at Germany’s University of Hohenheim, think it hints at how rubber could coexist with a natural ecosystem. [Source: Charles C. Mann, National Geographic, December 12, 2015]

“Unlike most nature reserves, Nabanhe is full of people. Its one hundred square miles include 33 small villages, with a total population of about 6,000. The land is divided into three zones. In the core, no human activity is allowed, as in a classic wilderness park. Surrounding that is a buffer zone, where people can live but are allowed only limited use of resources. And surrounding that is an experimental zone, where people can farm — that is, plant and tap rubber.

“The balance is difficult to maintain, Liu said. That afternoon we saw villagers ripping out illegal rubber plants. The malefactors had been turned in by their neighbors. Forestry police watched as the plants were dragged away. One of the police told me the villagers’ punishment hadn’t been severe — he just wanted them to be mindful of the rules.

“Langenberger believes that scientists should provide the facts and then let locals decide how to manage the landscape. “I don’t blame the farmers,” he said. “They’ve been poor here for so long. Now they have a crop that lets them participate in the world market.” Scientists can’t — and shouldn’t — “tell them to stop growing rubber,” he said. The logic of conservation is to forbid all human activity in the name of preserving vital rain forest. The logic of industry is to cover every scrap of land with rubber trees. Langenberger hopes it might be possible to create a state of productive tension. The Nabanhe Reserve, he hopes, could help show the way, a small effort to make things work in this tiny corner of the interconnected world.

Image Source: Mongabay mongabay.com ; Wikimedia Commons

Text Sources: “The Private Life of Plants: A Natural History of Plant Behavior” by David Attenborough (Princeton University Press, 1997); National Geographic articles. Also the New York Times, Washington Post, Los Angeles Times, Smithsonian magazine, Natural History magazine, Discover magazine, Times of London, The New Yorker, Time, Newsweek, Reuters, AP, AFP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated March 2022