EARTHQUAKE RESISTANT BUILDINGS IN JAPAN

Reinforced, earthquake-resistant buildings almost never collapse. Making a building earthquake-resistant adds about 10 to 20 percent to building costs. Things that can be done include reinforcing concrete walls and pillars, digging deep foundations, adding special joints that ease internal stress when buildings start to shake and sway.

In Japan all buildings must meet earthquake-safe building codes, which among other things, includes installing devises that automatically shut off the gas at the first tremor. Japan and some other countries have made an effort to strengthen dangerous buildings and infrastructure such as power plants, bridges and overpasses.

Earthquake resistant technology has been around for a long time. As early as 1891, it was suggested that buildings should be placed on rolling logs to absorb the horizontal movements of quakes before they reach the building. In the early 20th century, buildings were built with super thick pillars and limits were placed on heights. In 1928 "base-isolated pillars" were proposed that included deformable membranes between the foundations and the superstructure intended to absorb the quakes energy and slow oscillations.

Gojunoto is an earthquake-resistant pagoda erected in 1407 in Nara. The five stories oscillate in opposed phases when there are tremors, which keeps the structure from breaking apart. There is no evidence of the structure ever collapsing. The same techniques are used in modern buildings. The Yasaka Pagoda in Kyoto has survived more than five centuries of earthquakes. During a tremor the entire building sways as each story moves independent around a central anchoring pillar. Scientists are now studying the pagoda for clues on making modern buildings more earthquake-resistant.

Plans to improve Japan’s earthquake readiness includes making 90 percent of buildings earthquake-resistant and introducing subsidies and tax breaks to encourage citizens to make necessary change son their homes and anchor furniture so it doesn’t fall over. Currently 75 percent of the buildings in Japan are earthquake resistant.

The Tokyo government is considering passing laws requiring buildings along emergency transportation routes to conduct earthquake-resistance tests.

See Separate Article EARTHQUAKE RESISTANT BUILDINGS factsanddetails.com

Modern Earthquake Resistance Technology in Japan

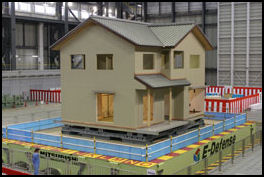

18-story model on earthquake protectors High rise buildings can be built with an elastic architecture that allows them to flex horizontally when the ground shifts. Earthquake resistant technology introduced in 1983 enabled concrete buildings and roads to be built atop layers of shock-absorbing rubber-bearing isolators and metal dampers. When an earthquake occurs the pads sway instead of the building. Most new buildings have this technology.

James Glanz and Norimitsu Onishi, New York Times, “Japan has gone much further than the United States in outfitting new buildings with advanced devices called base isolation pads and energy dissipation units to dampen the ground’s shaking during an earthquake. The isolation devices are essentially giant rubber-and-steel pads that are installed at the very bottom of the excavation for a building, which then simply sits on top of the pads. The dissipation units are built into a building’s structural skeleton. They are hydraulic cylinders that elongate and contract as the building sways, sapping the motion of energy.” [Source: James Glanz and Norimitsu Onishi, New York Times, March 11, 2011]

Japanese buildings tend to be much stiffer and stouter than similar structures in earthquake-prone areas in California. Japan’s building code allows for roughly half as much sway back and forth at the top of a high rise during a major quake. The difference, engineers say, comes about because the United States standard is focused on preventing collapse, while in Japan — with many more earthquakes — the goal is to prevent any major damage to the buildings because of the swaying.[Source: New York Times, March 11, 2011]

New apartment and office developments in Japan flaunt their seismic resistance as a marketing technique, a fact that has accelerated the use of the latest technologies, Ronald O. Hamburger, a structural engineer in San Francisco told the New York Times. “You can increase the rents by providing a sort of warranty.” “If you locate here you’ll be safe,” Mr. Hamburger said.

The most modern earthquake-resistant high-rises, using the latest base-isolation technology, rest on 30 layered rubber-bearing isolators, with 99 lead dampers below them. High-rise towers are strengthened with "super pillars" in the four corners and "supercrossbeams" at 10-floor intervals. Floors holding valuable computer systems have their own separate base-isolated floors. Buildings on softer soils need special braces because the building can resonate with the quake and vibrate apart.

Under Tokyo, construction crews have built tunnel-size ducts for water, electricity, telephone and sewage lines that are resistant to earthquakes. If damage does occur the tunnel-like designs allow quick access so services can be restored after an earthquake.

It is possible to build more earthquake-resistant buildings and highways, but for the number of lives saved, many argue that money for these expensive improvements would be better spent on traffic lights or child immunizations.

A 2010 survey by the Japanese Health. Labor and Welfare Ministry found that only 34 percent of Japan’s water mains are quake resistant.

Earthquake Resistant Homes in Japan

house shaker Because traditional Japanese homes are made of cedar wood and rice paper they catch fire easily. Moreover, they collapse easily under the weight of the heavy-tiled roofs.

Japan have traditionally not used stones or brick in construction because they are heavy and do not withstand quakes. Many houses built after World War II have walls composed of a thin lattice of light wood finished with stucco, and a roof made of heavy blue or brown tiles. Most people today live in concrete high-rises. Steel frame houses hold up well in earthquakes.

Most injuries at one hospital after the Kobe earthquake were the result of being crushed by falling beams or furniture. Measures that can be taken to reduce these kinds of injuries include using metal fittings to secure furniture to the walls of a house, attaching appliances to cabinets and tables with glue-like adhesive substances, reinforcing the ceiling and floors with steel girders and adding pillars and, or reinforcing existing pillars, strengthening the foundation by adding more concrete and steel.

The Japanese have developed a system for strengthening buildings up to a height of 30 meters with “made-to-break” T-joints, integrated into the design, that can be easily replaced and don’t require the building to be torn down and replaced. The T- joints are designed so the top part doesn’t break and the lower part does and the joint can be easily replaced.

The latest earthquake-ready homes are connected to Japan’s earthquake early-warning system, which can give up to 30 second notice before a quake hits, and have emergency lights, indoor sprinklers and secret fall-away doors that give every room two doors, increasing the change of escape;. Lights are covered in case the light bulbs expose and bathrooms have push out doors for walls to facilitate an escape.

The Japanese have designed panels made with highly abrasive and viscous dampers installed in the walls that absorb seismic energy before it reaches the joints between the pillars, cross ties and beams. The dampers are made with materials similar to those used in car breaks.

There is a high demand for quake-resistant tombstones, Conventional tombstones in Japan are made of several tiers of stones that are vulnerable to toppling over in a strong earthquake. New earthquake-resistant models are made with glued resin sheets between the stones. The sheets absorb shocks and hold the stones together.

Japanese Architecture, Wood, Earthquakes and Fire

It had traditionally been thought that one of the main reasons why wood was more dominant in Japanese architecture than stone is that wood structures were less vulnerable to earthquakes that stone buildings, which topple over easier. But this is not always the case. Wooden structures are often destroyed by earthquakes, plus they are generally more vulnerable to fire and typhoons than stone buildings. The stone castles built on Osaka Nagoya and other places to fend off the threat of European firearms, often survived earthquakes better than wood temples and shrines."

Providing a better explanation for dominance of wood, Edward Morse wrote in 1885, "The Japanese house answers admirably the purposed for which it was intended. A fireproof building is certainly beyond the means of a majority of these people, as indeed it is with us; and not being able to build such a dwelling, they have from necessity, built a house whose very structure enables it to be rapidly demolished in the path a conflagration."

"Mats, screen partitions, and even the board ceilings can be quickly packed up and carried away," Morse wrote. "The roof is rapidly denuded of its tiles and boards, and the skeleton framework left makes but slow fuel for the flames. The efforts of the firemen in checking the progress of a conflagration consist mainly in tearing down these adjustable structures; and in this connection it may be interesting to record the curious fact often times at a fire the streams are turned, not upon the flames, but upon the men engaged in tearing down the building!"

Gojunoto is an earthquake-resistant pagoda erected in 1407 in Nara. The five stories oscillate in opposed phases when there are tremors, which keeps the structure from breaking apart. There is no evidence of the structure ever collapsing. The same techniques are used in modern buildings. The Yasaka Pagoda in Kyoto has survived more than five centuries of earthquakes. During a tremor the entire building sways as each story moves independent around a central anchoring pillar. Scientists are now studying the pagoda for clues on making modern buildings more earthquake-resistant.

Measures Taken by Homeowners Against Ground Liquefaction

Ground liquefaction in a major earthquake can cause a house to tilt--or worse. In Japan measures against liquefaction are legally mandated in the construction of condominiums, but the requirement does not apply to building detached houses in most cases. If people want to check the ground strength or apply measures against liquefaction before building a house, they must enlist the help of specialists through housing contractors. [Source: Yomiuri Shimbun, December 14, 2011]

Tokai University Prof. Mamoru Fujii, an expert on liquefaction, said the liquefaction-induced tilting of a house can be at least partly prevented if the ground condition is strengthened. "However, it's necessary to decide the degree to which such measures should be taken based on [the household's] financial considerations and the scale of the envisioned earthquake," he said.

The first step is to determine whether the ground can be expected to cause liquefaction. Liquefaction is likeliest in sandy ground with a high level of groundwater. Reclaimed land, drained land and areas that used to be rivers belong to this category. To check the history of a plot of land, old maps, past aerial photos and charts that show the structure of the ground are useful. In Japan the cost for assessing ground quality is between $1,000 and $3,500.

Common reinforcement work when the ground is judged to be prone to liquefaction includes firming up the ground by mixing cement with soil, according to the organization. The cost can run from about $10,000 to $30,000 depending on construction methods for a two-story house with a footprint of 50 to 70 square meters. HyAS & Co. Inc., a Japanese company that reinforces ground, has been nationally promoting its "high-speed construction method," which refers to reinforcing the ground at a housing site by burying crushed stones in the soil in a pillarlike structure.

Earthquake Resistant Homes and the Japanese Government

earthquake building experiment An estimated 75 percent of the houses in Japan are earthquake-proof. The government wants to raise the figure to 90 percent. To this end the government has provided tax incentives and subsidies for people who want to make earthquake-resistant improvements to their houses.

James Glanz and Norimitsu Onishi, New York Times, “In Japan, where earthquakes are far more common than they are in the United States, the building codes have long been much more stringent on specific matters like how much a building may sway during a quake. After the Kobe earthquake in 1995, which killed about 6,000 people and injured 26,000, Japan also put enormous resources into new research on protecting structures, as well as retrofitting the country’s older and more vulnerable structures. Japan has spent billions of dollars developing the most advanced technology against earthquakes and tsunamis.

Earthquake-proofing laws are surprisingly vague. Real estate agents often do not disclose the true condition of the properties they sell. Houses built before the 1981 were built before earthquake standards were imposed. Those built after the Kobe earthquake in 1995 are best because strict laws were imposed after that.

An effort is being to install earthquake-resistant technology in older houses and provide subsidies to cover the costs. In most cases if the costs exceed $10,000 the subsidy with cover about 60 percent of the costs. Poorer, older people especially are reluctant to shoulder the cost. For them the government is trying to convince them to put earthquake-resistant technology in a single room with the idea being that if they improve a single room the chances of the entire house collapsing are lessened.

It estimated that 11.5 million homes nationwide fail to live up to government quake tolerances standards set in 1981. Many are wooden houses built before 1981. The renovation usually involve installing pillars, diagonal crossbeams or walls that make the structure strong. The renovations typically cost about $30,000. The government provides subsidies that pay for about a forth of the cost of making the old homes earthquake resistant.

Although many older buildings in Japan have been retrofitted with new bracing since the Kobe quake, there are many rural residences of older construction that are made of very light wood and heavy roof tiles that make them highly vulnerable to damage. Earthquake proofing has not been applied to many school and hospitals, which are evacuation sites in the event of a quake.

Much of the money made available by various local and national governments for making one’s home more resistant to earthquakes goes unused.

Earthquake Resistant Building Scandal in Japan

In 2005 and 2006 there was a big scandal over the falsifying of data related to the earthquake resistance of some buildings. Resident of condominiums were forced to move out and hotels were forced to close. Much f the blame was placed on the architect Hidetsugu Aneha, who fabricated the data. Aneha said he was pressured by his clients in the construction industry to fudge the data so they could save money in building costs.

In investigation revealed that Aneha fabricated data for 99 condominiums and hotels, making them susceptible to collapse in a upper 5 level earthquake. The buildings are supposed to be able to withstand level 7 earthquakes.

Aneha reported that the buildings he checked had more steel reinforcing than they actually had. Aneha said he did it because was asked by the manager of a construction company to reduce the amount of steel reinforcement with the understanding that the manager knew that would weaken the building. Aneha said if he didn’t comply he would lose business.

Aneha later said originally faked data to make a name for himself as a cost cutter and then kept on faking data to maintain his reputation. He was sentenced to five years in jail. The scandal raised questions about the credibility of the construction industry as a whole and hurt the properties business.

Image Sources: Disaster Prevention Research Institute, University of Kyoto, USGS

Text Sources: New York Times, Washington Post, Los Angeles Times, Daily Yomiuri, Times of London, Japan National Tourist Organization (JNTO), National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated April 2022