FINDING NEW SOURCES OF RARE EARTHS

Foreign companies and governments are scrambling to find new sources of rare earths as China threatens to further tighten restrictions or even ban exports of some elements and close mines. Dudely Kingsnorth, an Australia-based independent rare earth analyst, told AFP, “It’s crunch time, In the next few years, we are going to be in a situation where [export and production] quotas are reduced and unless we have sources outside China, more companies are going to have to relocate to China to secure access.”

In the wake of China's tougher restrictions, alternative mines have been explored across the globe. However, economists predict that the world will rely on China for dysprosium in the foreseeable future.There are rare earth mines with minimal production in Russia, India and Brazil. Deposits are also being developed in Australia and United States. These will produce about 50,000 tons of rare earths by 2014. This is not enough to keep up with demand, with some analyst predicting a tight market starting in 2012 and severe problems if there are delays in the Australian and U.S. projects.

James Lifton, an independent U.S.-based rare earths analyst, told AFP, “China’s goal is to create jobs in China and create goods in China . We need to start producing these metals here [in the United States] as we did in the past. If we don’t do that, China will be the only country manufacturing devises using rare earth by the year 2015.”

Ren Xianfang, a Beijing-based economist with IHS Global Insight, told AFP, “The government hopes the restrictions could prompt the transfer of advanced rare earth processing technologies into China. Whether this resource-in-exchange-for-technology strategy will work in favor of China remains to be seen.”

Rare Earths and Other Countries

search for rare earths

Although China currently monopolizes rare earth mining (with 36 percent of the world's reserves), other countries have deposits too. Russia has the largest reserves of rare earths after China. According to U.S. government data it holds 19 percent of the world’s 99 million tons of commercially viable rare earths. The United States has 13 percent. Australian has five percent. Namibia, Mongolia, Malaysia, Kyrgyzstan, Vietnam, Kazakhstan and Canada have substantial deposits as well. Kazakhstan is the world’s second largest producer of rare earths, but it produces only about 4.5 percent of the world’s supply. The United States and Australia mined rare earths in the past but stopped mining them because of cheaper competition from China.

Global rare earth reserves (total 99 million tons); 1) China (36 percent ); 2) former Soviet countries (19 percent); 3) the United States (13 percent); 4) Australia (6 percent ); 5) India (3 percent ); 6) Others (23 percent). [Source: Japan’s Economy, Trade and Industry Ministry, 2009]

Companies in Australia, Canada and Brazil are on the hunt for rare earth sites. Heightened interest in alternative sources has also been an impetus to plans to reopen or establish new rare earth mines in a handful of countries around the world, including South Africa, Russia Australia and Canada. An additional 40,000 tons is expected to come form non-Chinese sources in coming years.

The Lynas Corp, won the right to mine world’s richest non-Chinese deposit of rare earths, in Australia. It will be at least until 2012 before it is capable of mining the deposit. Other rare earth companies include China Rare Earth Holdings, Arafura resources, Alkane resources and Greenland Minerals and Energy

rare earths Brazil has the world’s largest know deposit of niobium. It is said to be large enough supply the world for 500 years at current consumption rates. Some in Russia claim that Yakutia’s Tontorskoye in Siberia “is many times bigger in volume and quality than Brazil’s famous deposits.”

The European Union said it might 1) start stockpiling rare earths; 2) strengthen ties with African countries that have rare earth deposits; 3) take measures to discourage speculation of rare earths; and and consider nullifying most-favored-nation treatment to countries (i.e. China)that try to restrict supplies of rare earths and other strategically important raw materials.

Yoichi Saito of Mitsui believes that China will use it monopoly status in rare earths to crush competition. Although other places have reserves of rare earths, few places have significant refinery capacity. Refineries require a lot of investment to set and China could easily undercut prices of materials produced by rival sources. Saito told Times, “Many people are looking at establishing alternative refineries and sources outside China, but the investment is not necessarily a sound one because of the threat of price revenge by China. If new projects emerge as they have recently in Malaysia and Australia, China could just drop its prices and rivals are out of business.” China is also taking steps to corner the marker globally. In early 2009, for example, it acquired 25 percent of Arafura Resources, a Australian rare earth miner.

Some suggest recycling existing rare earths materials — known as "urban mining." Others are considering using substitute materials such as aluminum, copper and iron in place of rare earths.

Rare Earths in Greenland and the Sea

Recently a large source of rare earth was found in southwestern Greenland in geological strata called the Ilimaussaq Intrusion. The find could enrich Greenland and make China’s monopoly on rare earth a thing of the past. The Ilimaussaq Intrusion lies on a desolate plateau and is thought to contain the largest known reserves of rare earths. An Australian mining company has the rights to mine the site and it plans to process about 50,000 tons of rare-earth-bearing ore by 2010.

In July 2011, Japan announced it had found abundant rare earth elements on the sea floor of the Pacific ocean. The Yomiuri Shimbun reported: “Mud on the seafloor in certain areas of the Pacific Ocean contains about 800 times the amount of rare earth elements found in deposits on land, a Japanese research team has reported in the electronic version of the British magazine Nature Geoscience. The nine-member team, which includes University of Tokyo Associate Prof. Yasuhiro Kato, said it located the deposits in ocean-floor mud at depths of 3,500 meters to 6,000 meters in central and southeastern areas of the Pacific Ocean.” [Source: Yomiuri Shimbun, July 5, 2011]

The group believes deep-sea mud constitutes a highly promising source of these elements."If the technology to exploit them efficiently is developed, it would be possible for the deposits to become an alternative to land-based rare earth elements," Kato said. The group analyzed the elemental composition of more than 2,000 seafloor sediments, sampled from a wide stretch of areas in the Pacific Ocean during international deep-sea drilling projects in which Japan and the United States participated.

It found high concentrations of rare earth minerals, equivalent to those found in mines on land, in deep-sea mud 23.6 meters thick in the central Pacific Ocean, including near the Hawaiian Islands. It also found such deposits in southeastern waters around the French Polynesian island of Tahiti, in mud eight meters thick. Estimating from points where the sediments were sampled, the group believes the deposits are distributed over an area of about 8.8 million square kilometers in the central Pacific and an area of about 2.4 million square kilometers in the southeastern Pacific.

Rare Earths and Japan

Chinese rare earth mine Japan imports of rare earths from China accounted for about 82 percent of Japan's imports of rare earths in 2010.The Economist reported: “Japan imports more rare earths than any other country. Its electronics, fine-chemicals and car industries rely on them. A disruption of supply could paralyse the Japanese economy as much as an oil embargo or food blockade. And because Japan dominates some of the technological processes that use rare earths’such as polishing hard-drive platters with cerium oxide — interrupted access would be felt worldwide. [Source: The Economist, January 20, 2011]

Japan is the largest consumer of rare earths. It uses a fifth of the world’s supply. It is predicted to face a rare shortage of 11,300 tons in 2011. China’s rare earth exports (50,000 tons in 2009); 1) Japan (56 percent); 2) the United States (17 percent); 3) France (6 percent); 4) Others (21 percent) [Source: Japan’s Economy, Trade and Industry Ministry]

Japan gets 90 percent of its rare earths from China. Hiroko Tabuchi wrote in the New York Times, “Japanese companies generally avoid discussing their mineral holdings. But experts say that some manufacturers have been stockpiling rare earths, building inventories ranging from a few months’ to a year’s worth. In September 2010 the Japanese trade minister, said the government was considering starting a stockpile of rare earths as a buffer against trade interruptions. [Source: Hiroko Tabuchi New York Times, October 4, 2010]

China Bans Rare Earth Exports to Japan

rare earth mine In early September 2010, when a major diplomatic row broke out between Japan and China over a group of disputed islands after a Chinese trawler collided with two Japanese Coast Guard, China effectively imposed a ban on the export of rare earths and silicon — materials critical in the electronics and automobile industry and of which China is one of the sole suppliers — by initiating customs procedures such as requiring documents to be in Chinese, a deviation from usual practices, that halted the shipments. All 31 Japanese companies involved in the rare trade said their businesses had been hampered by the Chinese export restrictions.

Customs restrictions in rare earths remained in place even after the captain of the Chinese ship at the center of the dispute was released. An industry official said, though a trickle of shipments seemed to be seeping out as a result of uneven enforcement of the ban by customs officers at various ports. China has allowed exports of Chinese-made rare earth magnets and other rare earth products to Japan, but not semi-processed rare earth ores that would enable Japanese companies to make products. Finally, about five days after the captain was released China began to back down. The rhetoric was toned down. Customs procedures returned to normal and shipments or rare earths and materials resumed. [Source: Hiroko Tabuchi New York Times, October 4, 2010]

Paul Krugman wrote in the New York Times, “Even before the Then came the trawler event. Chinese restrictions on rare earth exports were already in violation of agreements China made before joining the World Trade Organization. But the embargo on rare earth exports to Japan was an even more blatant violation of international trade law...Oh, and Chinese officials have not improved matters by insulting our intelligence, claiming that there was no official embargo. All of China’s rare earth exporters, they say — some of them foreign-owned — simultaneously decided to halt shipments because of their personal feelings toward Japan. Right.” [Source: Paul Krugman New York Times, October 17, 2010]

Hiroko Tabuchi wrote in the New York Times, “The cutoff has caused hand-wringing at Japanese manufacturers, from giants like Toyota to tiny electronics makers, because the raw materials are crucial to products as diverse as hybrid electric cars, wind turbines and computer display screens. Japan’s trade minister, Akihiro Ohata, said he would ask the government to include a “rare earth strategy” in its supplementary budget for this year. [Source: Hiroko Tabuchi New York Times, October 4, 2010]

“So what are the lessons of the rare earth fracas?” Krugman asked. “First, and most obviously, the world needs to develop non-Chinese sources of these materials. There are extensive rare earth deposits in the United States and elsewhere. However, developing these deposits and the facilities to process the raw materials will take both time and financial support. So will a prominent alternative: “urban mining,” a k a recycling of rare earths and other materials from used electronic devices.” [Krugman, Op. Cit]

Japan Responds to Chinese Rare Earth Quotas

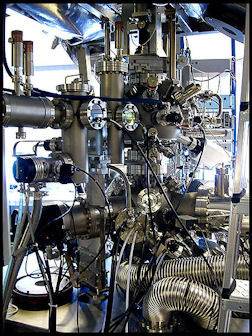

vacuum chamber used to study

rare earth surfaces The Economist reported: “Two decades of economic impotence have convinced many observers that Japan is cautious and slow to change. But the country can move quickly when sufficiently provoked?...for example by... “China’s hoarding of rare earths. Since shipments of rare earths were cut off over the island dispute in September 2010 Japan Inc has sprung into action. [Source: The Economist, January 20, 2011]

“The big trading houses such as Sojitz, Sumitomo and Mitsubishi are securing alternative supplies, supported by state financing. Companies such as Toyota, Hitachi, Nidec and TDK are working to reduce or eliminate the rare-earth elements needed in devices. Recycling programmes are being studied. The government earmarked $1 billion from a stimulus package in November to secure supplies, including funding university research and projects such as robotic deep-sea mining.”

“A national stockpile of the kind that already exists for rice, cereals and petrol has been mooted. There is even talk of creating a generously funded agency to acquire stakes in non-Chinese producers, possibly using the country’s vast foreign-exchange reserves (at $1 trillion, the world’s largest after China’s). Japan’s prime minister has met his Vietnamese and Mongolian counterparts to discuss new production.”

“Japan has been suddenly spurred to action before. The environmental crisis in the 1960s, the oil shocks of the 1970s and the strong yen in the 1980s rallied bureaucrats, politicians, business leaders, the media and the public. High energy prices forced Japan to become one of the world’s most energy-efficient countries....Japan will remain dependent on Chinese rare earths for some time. The country’s resource mandarins say they have no specific target for reducing this dependency, though they reaffirm an earlier goal that Japan should control 50 percent of its mineral needs, including rare earths, by 2030. “

Japan Seeks Alternative Source of Rare Earths

Rare earth magnet

and Ferro fluid The fallout over the Chinese fishing boat in waters of the disputed Senkaku islands in September 2010 and the blocking of rare earth exports, accelerated Japan’s quest for alternative sources of rare earths and development of technologies that didn’t need rare earths so it wasn’t so dependant on China for them.”

Days after the effective export on rare earths from China to Japan was imposed the Japanese Economy and Trade Minister Akihiro Ohata established a new rare earth policy aimed at diversifying Japan supply and stockpiling the materials. Ties were firmed up with Kazakhstan, the world’s second largest producer of rare earths after China, and Vietnam and Mongolia, two other large rare earth producers. Kazakhstan was told to send representatives to Japan as soon as possible to negotiate and expand its rare earth deal with Japan.

In November 2010, Sojitz, a large Japanese conglomerate, announced a deal with Lynas, an Australian mining company, to secure rare earths through 2020s. According to the agreement Sojitz would receive 70 percent of Lynas’s annual 22,000 ton annual rare earth capacity. In March 2011, a consortium of Japanese and South Korean companies — including Nippon Steel and JFE Steel of Japan and POSCO of South Korea’said they were buying a 15 percent stake in Companhia Brasileira de Meltalurgiae Mineracao (CBMM) — a major rare earth mining firm and producer of niobium in Brazil for about $1.7 billion. Sojitz is also negotiating the rights to a rare earth mine in Vietnam. The industrial conglomerate Sumitomo plans to work with Kazakhstan’s government to recover rare earth elements from uranium ore residues.

The Japanese companies Mitsui and Sumitomo Corp., are exploring the possibility of mining rare earths from deposits in Siberia that weren’t expected to be exploited until 2030. The company talked with government officials in Yakutia — an area of northeastern Russia the size of India with frigid winters and only about 1 million people “about mining deposits of niobium and scandium. [Source: Bloomberg]

Geoff Bedford of the rare-earth-processor Neo Technologies, told AFP, “We do not have a customer in Japan whose research and development group is not working overtime to figure out how to reduce, or eliminate, rare earths in their products.”

Japan has budgeted $1.25 billion — equal to the total annual rare earth market value — in 2011 to secure non-Chinese supplies. In October 2010, Japan and the United States agreed to cooperate to diversify suppliers after China announced it was going to curb exports. In February 2011, the Japanese government decided to give $360 million to 169 projects to encourages firms to cut their use of rare earths,

Japan Seeks Recycled Rare Earths from Urban Mining

The National Institute for Materials Science, a government-affiliated research group, says that used electronics in Japan hold an estimated 300,000 tons of rare earths. Though that amount is tiny compared to reserves in China, tapping these urban mines could help reduce Japan’s dependence on Chinese sources. Reporting from Kosaka, Japan, Hiroko Tabuchi wrote in the New York Times, “Two decades after global competition drove the mines in this corner of Japan to extinction, Kosaka is again abuzz with talk of new riches. The treasures are not copper or coal. They are rare-earth elements and other minerals that are crucial to many Japanese technologies and have so far come almost exclusively from China, the global leader in rare earth mining. This town’s hopes for a mining comeback lie not underground, but in what Japan refers to as urban mining — recycling the valuable metals and minerals from the country’s huge stockpiles of used electronics like cellphones and computers.” “We’ve literally discovered gold in cellphones,” said Tetsuzo Fuyushiba, a former land minister on a visit to Kosaka’s recycling plant.” [Source: Hiroko Tabuchi New York Times, October 4, 2010]

“In Kosaka, Dowa Holdings, the company that mined here for over a century, has built a recycling plant whose 200-foot-tall furnace renders old electronics parts into a molten stew from which valuable metals and other minerals can be extracted. The salvaged parts come from around Japan and overseas, including the United States. Besides gold, Dowa’s subsidiary, Kosaka Smelting and Refining, has so far successfully reclaimed rare metals like indium, used in liquid-crystal display screens, and antimony, used in silicon wafers for semiconductors. The company is trying to develop ways to reclaim the harder-to-mine minerals included among the rare earths — like neodymium, a vital element in industrial batteries used in electric motors, and dysprosium, used in laser materials.”

“Various players have tried to recycle rare earths and metals in Japan. Last year, Hitachi began to experiment to extract rare earths from magnets in old computer hard drives, though the company said the project was not expected to go into operation until 2013. But it is Dowa, the company that has mined in Kosaka since 1884, that has emerged as the field’s early leader. And it could not come a moment too soon for this town of 6,000, which is littered with the remnants of its old ore mines: tunnels overgrown with weeds, old railroad tracks, and an abandoned bathhouse where miners once sponged off the grime from their long days underground. The mines operated up to 1990, until a surging yen and international competition drove operations out of business. Now, portions of the old red-brick ore processing factories serve as part of Dowa’s recycling plant, which started fully operating two years ago.”

La2O3 structure “It is important for Japan to actively tap its urban mines,” Kohmei Harada, a managing director at the National Institute of Materials Science, told the New York Times. He is an enthusiastic supporter of recycling efforts like the one in Kosaka. Apart from rare metals and earths, Mr. Harada estimates that about 6,800 tons of gold, or the equivalent of about 16 percent of the total reserves in the world’s gold mines, lie in used electronics in Japan. “Japan’s economy has grown by gathering resources from around the world, and those resources are still with us, in one form or another,” he said.

“But this form of recycling is an expensive and technically difficult process that is still being perfected. At Dowa’s plant, computer chips and other vital parts from electronics are hacked into two-centimeter squares. This feedstock then must be smelted in a furnace that reaches 1,400 degrees Celsius before various minerals can be extracted. The factory processes 300 tons of materials a day, and each ton yields only about 150 grams of rare metals. Though Dowa does not disclose the finances of its Kosaka recycling operations, the company says that after a year of operating at a low capacity, the factory now turns a profit. Over all, net income at Dowa Holdings, which deals in industrial metals and electronic materials, almost tripled in the quarter ending June 30, to 6.52 billion yen, or $78.2 million, as global industrial production rebounded.”

Utaro Sekiya, the manager of Dowa’s recycling plant, said, “It’s about time Japan started paying more attention to recycling rare earths...If we can become a leader in this field, perhaps China will be the one coming to us to buy our technology.” Tabuchi wrote: “As Dowa has turned its attention to rare earths, a priority is developing ways to render neodymium, which is used in powerful magnets. Its extraction has proved costly. Neodymium is found only in tiny quantities in parts used in the speakers of cellphones, for example, making it a challenge to collect meaningful amounts, said Sekiya... Finding enough electronics parts to recycle has also grown more difficult for Dowa, which procures used gadgets from around the world. A growing number of countries, including the United States, are recognizing the value of holding onto old electronics. And China already bans the export of used computer motherboards and other discarded electronics parts.”

Rare Earths in the United States

Until the 1980s, the United States led the world in rare earth production, thanks largely to the Mountain Pass mine in California. "There was a time we were producing 20,000 tons a year when the market was 30,000 tons," Mark A. Smith, president and CEO of Molycorp, an American company that reopened a rare earth mine at Mountain Pass, told National Geographic. "So we were 60-plus percent of the world's market."

Tim Folger wrote in National Geographic, “American dominance ended in the mid 1980s. China, which for decades had been developing the technology for separating rare earths... entered the world market with a roar. With government support, cheap labor, and lax or nonexistent environmental regulations, its rare earth industries undercut all competitors.” Mountain Pass was closed in 2002 after an industrial accident and because of competition from China and environmental concerns. [Source: Tim Folger, National Geographic, June 2011 ]

The California deposit was discovered in the 1940s by uranium prospectors. It became the world's largest supplier of rare earths as the demand for europium, which is used for color television screens, surged in the 1960s. When the mine closed it left behind mounds of tailings, or leftover dirt, around the property.

Many wonder how the United States could let itself become so dependant on its rival China — and vulnerable to supply cut offs — for strategic minerals like rare earths. Paul Krugman wrote in the New York Times, “You really have to wonder why nobody raised an alarm while this was happening, if only on national security grounds. But policy makers simply stood by as the U.S. rare earth industry shut down. In at least one case, in 2003 — a time when, if you believed the Bush administration, considerations of national security governed every aspect of U.S. policy — the Chinese literally packed up all the equipment in a U.S. production facility and shipped it to China. [Source: Paul Krugman New York Times, October 17, 2010]

“The result,” Kugman wrote, — was a monopoly position exceeding the wildest dreams of Middle Eastern oil-fueled tyrants. And even before the trawler incident, China showed itself willing to exploit that monopoly to the fullest. The United Steelworkers recently filed a complaint against Chinese trade practices, stepping in where U.S. businesses fear to tread because they fear Chinese retaliation. The union put China’s imposition of export restrictions and taxes on rare earths — restrictions that give Chinese production in a number of industries an important competitive advantage — at the top of the list.”

In October 2010, the U.S. House of Representatives approved a bill authorizing research to address the supply of rare earths, saying the minerals were critical to energy, military and manufacturing technologies. The U.S. rare earths industry is hoping domestic mines will open. The U.S. Geological Survey has identified several sites, including Music Valley in Southern California, where rare earths could be mined. Congress is considering proposals, some pushing for loan guarantees for rare earths suppliers, to encourage more domestic research and production. [Source: New York Times, Los Angeles Times]

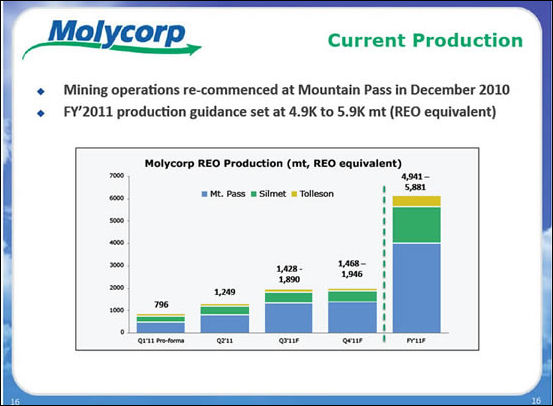

Molycorp Mine

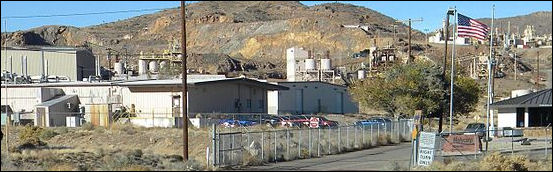

In the Mojave Desert just off Interstate 15 on the way to Las Vegas, the Colorado-based mining company Molycorp runs Mountain Pass mine. It produces about 3 percent of the world's rare earths, but the company plans to eventually turn out a quarter of the total supply. The main problem with the site is that it produces only light rare earths such as neodymium and cerium not the more valuable heavy ones. [Source: Tiffany Hsu, Los Angeles Times, February 20, 2011]

Tiffany Hsu wrote in the Los Angeles Times, “The mine, about 16 miles from the Nevada border, covers an area of about nine square kilometers. It has one of the world's largest deposits of rare earth elements outside Asia and is the only commercial producer in the Western Hemisphere. Many hope the Mountain Pass facility will help loosen China's chokehold on rare earths mining and manufacturing. Investors recently pushed Molycorp stock to $50 a share in February 2011 from its $13.25 debut price in July 2010.”

“The company is spending more than $500 million to modernize and rebuild the 2,200-acre facility. The hope is to produce 3,000 tons of rare earths in 2011 and up that figure to 20,000 tons by late 2012 and eventually produce 40,000 tons. Molycorp hopes to produce the minerals at a cost of $2.77 per kilogram. The project is expected to create hundreds of permanent jobs and eventually produce rare earths at cheaper rates than mines in China.”

“Molycorp is now cleaning up the site, implementing a water recycling program, constructing an on-site natural gas power plant and planning to work the tailings back into the surrounding landscape. It hopes save money using power generates rom natural gas and using advanced technology to purify slat water that gushes out at the site. San Bernardino County officials hope the activity attracts battery manufacturers and other clean-tech companies, creating a hub of research and innovation in the area.”

Molycorp intends to produce 3,000 to 5,000 tons of rare earths from stockpiled ore at its Mountain Pass mine this year and has big expansion plans. "The current U.S. demand is somewhere between 15,000 and 18,000 tons per year," Smith told the Los Angeles Times. "In principle, Mountain Pass could eventually make the United States independent in rare earths." The $531 million cost of redeveloping the mine has been covered by a selling of shares on the New York Stock Exchange and a $100 million financing deal from Sumitomo and a major French bank. The large Japanese trading houses Sumitomo and Mitsubishi have invested heavily in Molycorp.

Mountain pass mine

Problems Developing Rare Earths in the United States

Tiffany Hsu wrote in the Los Angeles Times, “But developing a new mine from scratch requires prospecting, exploration, permitting and construction. And even if more mines open in the U.S., the country has few companies that can process rare earths, use them to manufacture batteries and magnets and work them into products. Without a domestic supply chain, most of the material extracted in the U.S. would have to be shipped overseas anyway.” [Source: Tiffany Hsu, Los Angeles Times, February 20, 2011]

“There aren't many researchers or industry workers in the U.S. with experience working with rare earths. Not long ago, Molycorp recruiters were unable to find potential hires or even universities that offered rare earths courses. The company has 22 scientists exploring uses and sources of the elements; China has thousands.” "It takes a lot to go from some dirt in the ground to magnets," rare earths expert Jack Lifton told the Los Angeles Times. "Finding a deposit is like saying, 'George Washington slept here.' It doesn't mean much. We've got enough bananas, but now we've got to figure out how to make banana splits."

“But some clean-tech executives said that the industry may be relying too much on rare earths,” hsu wrote. “Metallurgy experts point to the cobalt crisis of the late 1970s as an example. The element — used in alloys, batteries, pigments and more — was in short supply as political unrest locked down the primary reserves in Africa just as demand was starting to boom.” "Tomorrow, it'll be something else," said Alexander King, director of the Ames Laboratory in Iowa, run by the Energy Department. "The thing we need to learn is how to control the economics, to develop alternative materials on a very short turnaround."

rare earth mine

Alternatives to Rare Earths

Some say the answer to rare earth dependancy problem is finding alternatives to rare earths materials and using substitute materials such as aluminum, copper and iron in place of rare earths. Japan is pushing for new manufacturing processes that do not require rare earths. In September 2010, the government-affiliated New Energy and Industrial Technology Development Organization, or N.E.D.O., announced that it had developed a motor for hybrid vehicles that used cheap and readily available ferrite magnets, instead of the rare earth magnets typically required. Dubbed as the world’s first rare-earth free high-performance motor for hybrid vehicles, it was developed jointly with Hokkaido University. The motor produces 50 kilowatts of power — the same as a Prius. [Source: Hiroko Tabuchi New York Times, October 4, 2010]

“Japanese companies have become painfully aware of the risks of relying so greatly on China for strategic metals,” Akio Shibata, chief representative at the Marubeni Research Institute in Tokyo, told the New York Times. He said Japanese industry might benefit from researching alternatives to rare earths and developing recycling methods, noting how the oil shocks of the 1970s helped eventually make Japan a leader in fuel-efficiency technologies.” Geoff Bedford of the rare-earth-processor Neo Technologies, told AFP, “We do not have a customer in Japan whose research and development group is not working overtime to figure out how to reduce, or eliminate, rare earths in their products.”

Toyota Motor Corp., which uses rare earths for hybrids like the Toyota Prius, said it plans to switch to motors that doesn't require the elements. In January 2011, Toyota announced it had made great advanced in developing future hybrid and electric engines that didn’t rare earths. The main technology behind the advance is the development of an “induction” motor that is lighter and more efficient that the magnetic type now used in the Prius. One of drives behind developing such motors is so Toyota won’t be caught out in the cold if supplies of rare earths suddenly dry up. Hitachi Metals is working on a magnet that minimizes the use of rare earths by employing copper alloys.

Pete Savagian, chief engineer for electric motors for General Motors Co., said that managing fluctuating supply is a "normal risk of doing business." If rare earths run low or are priced out of the market, the automaker will adapt, he said. "Rare earth magnets are great to have, but they're also not the only way," he said. "We'll go forward using the best methods we have.”

Image Sources: Wikipedia, Wiki Commons, Reuters, Molycorp

Text Sources: New York Times, Washington Post, Los Angeles Times, Times of London, National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated April 2012