INDUSTRY IN CHINA

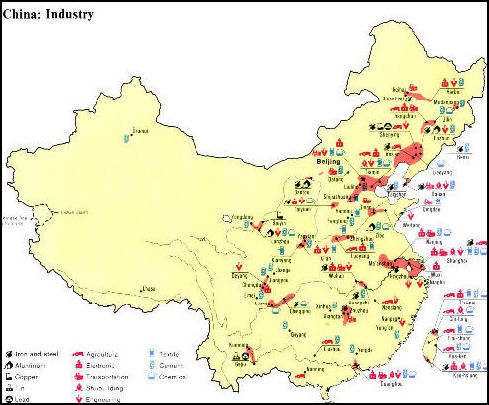

Steel factoryChina is world's largest producer of steel, coal, cement, grain, cotton, meat and fish and the world’s dominant manufacturer for a wide range of products, including toys, fax machines, sports shoes, furniture, laptop computers and cameras.. Chinese industrialization began with textiles, and China remains the leading producer of woven fabrics. Other major industries are chemicals, electronics and armaments. Steel, nonferrous metals, cement and chemicals suck up 29 percent of China’s electricity.

In China, factories are erected with remarkable speed and retooled for new products with equally impressive speed — both important element of China’s rapid manufacturing rise. According to the consulting firm IHS Global Insight, China accounted for 18.6 percent of the world’s gross manufactured output in 2009. In 2010 it is expected to surpass the U.S., which had a 19.9 percent of the output in 2009. As of 2008, about 89 percent China’s high-tech exports came from non-Chinese-owned companies.

Sometimes China is referred to as the “world’s factory.” The term is sometimes used to refer in particular to Shenzhen and the Pearl River Delta in Guangzhou. The industrial heartland during the Mao era was in the northeast provinces of Liaoning, Jilin and Heilongjiang. This area went through a period of decline in the 1990s and early 2000s and now is attempting to resurrect itself.

China is experiencing an industrial revolution at about ten times the speed that it occurred in the West. China relies on energy-driven heavy industry to generate growth. Between 1980 and 2000 China relied mainly on light industry to generate growth. The shift from light industry to heavy industry has lead to a huge appetite for resources and energy and produced huge amounts of pollution. Steel, for example, uses up 16 percent of all of China’s power, compared to 10 percent for all the country’s households combined and produces lots of pollution.

Few of the products made in China are actually created or designed there. Most of the products are made for foreign companies using designs and patents from foreign companies, with foreigners making the biggest profits.Only 35 cents from an exported toy retailing for $20 remains in China.

Long supply chains with multiple contractors and subcontractors are common in China. Often they only thing that hold them together is trust which leaves open the possibility for fraud, and contaminated goods. When the process breaks down or there is some problem it is often difficult to ascertain clearly who as fault.

Chinese manufacturers of electronics and automobiles and other products was hurt parts shortages caused by the tsunami in Japan. China was particularly hard hit because as the world’s factory it has so many manufacturers and those made cars, refrigerators, iPods, flat-screen televisions, laptops and other stuff all need parts made by Japanese factories shut down by the earthquake and tsunami.

See Separate Article INDUSTRIES IN CHINA factsanddetails.com

Mao-Era Industry

In the Mao era, heavy industry was emphasized, with the government supporting large infrastructure projects and industries such as steelmaking and heavy machine making. Large factories were like cities unto themselves, with hospitals, schools, housing and cradle-to-grave social programs for their workers. Factory management and work units in many ways served as local and community government.

A primitive industrialized society was established a huge cost, namely in terms of pollution, inefficiency and poor production. Industries were heavily subsidized and profits were regarded as an important consideration. . The production cost of some products was three times their selling price.

State-owned enterprises ran 18,000 schools, 19,000 nurseries, and 224,000 hospitals, as well as restaurants, plumbers, electricians, florists, transportation services and police units. Some factories were the size of enclosed foot-ball fields. A successful factories was one that employed lots of people not necessarily one that made a profit. Most Han Chinese in Xinjiang (2.2 million of them) worked for the Production and Construction Corps, an organization that came to Xinjiang in the 1950s and now runs factories, farms and other enterprises.

In the Communist era, the government supported heavy industry such steel making, and heavy machine making and large infrastructure projects and supported enterprises that produced an illogical array of good such as cooking pans, washing machines and high-performance aircraft.

In the Mao era, the writer Paul Theroux said that the Chinese make 18th century products in 19th century factories. Chinese factories were among the last in the world to make — and still make today — quill pens, treadle sewing machines, wooden yokes for oxen, iron plows, washboards, spittoons, chamber pots, bed warmers, corsets, backscratchers, and fish glue. The Yantai Woolen Needlepoint Tapestry Factory still makes tapestries of works by da Vinci, Vermeer, Rembrandt as well as ones of kittens playing with balls of yarn.

In the 1970s, clocks were in such short supply that only people who displayed a marriage certificate could buy one. Other products from this era include sit-up-and-beg bicycles, steam engines, a Chinese version of the 1948 Packard car ( "The Red Flag") and the chain driven mechanical grandfather clocks. Popular products included White Rabbit candies, Bat electric fans, Phoenix bicycles and Golden Dragon vegetable oil.

After the Deng reforms, factories were pressured to make money or at least not loose so much. One way that this was achieved was breaking large factories into subsidiaries that were each responsible for making a profit. Many factories were closed down. Some were changed to factories that made things like air conditioners and furniture. Others were abandoned and still sit empty today.

See State-Owned Enterprises, Macroeconomics

Steel in China

China is by far the world’s largest consumer and producer of steel. It consumes and produces about a third of the world’s steel, more than Japan, Germany and the United States combined. Even though it is the world’s largest producer it has to import steel to meet its demand. Not only that it needs so much nickel to make stainless steel, the world demand for nickel has increased at a rate equal to half the total consumption of nickel in the United States.

China’s crude steel output jumped 13.5 percent in 2009 from the year before to 567.84 million tons, accounting for half of global production. Steel output rose to 316 million metric ton in 2005 up from 273 million metric ton in 2005. Production in 2006 rose 18.5 percent to 348 million tons despite efforts to slow investment and reduce pollution. The high number of steel mills indicates that China will be the world’s largest steel producer for some time. In 2006, China consumed more than twice as much steel as the United States (258 million tons compared to 104 million tons) and surpassed Japan and the European Union to become the world’s largest steel exporter. .

In 1996, China became the world's top producer of steel, beating the long time leader Japan. Production increased by 5 percent from the year before to 100.4 million tons compared to Japan's 98.8 million tons. After that China added the equivalent steel making capacity of Japan and South Korea in five years.

Demand for steel has increased dramatically as the auto, construction and oil and gas industries have grown. Construction accounts for two thirds of steel consumption. Steel is used in ships, cars and appliances. The Chinese claim that their gigantic steel factories, with thousands of machines and workers, produce enough steel cable to encircle the globe each day. Steel uses up 16 percent of all of China’s power, compared to 10 percent for all the country’s households combined.

Hebei Province is home to one fifth of China’s steel production capacity. One of the largest steel mills in the world is in Baotou, Inner Mongolia. Some 170,000 of the city two million people work in steel production. The massive Anshan metalworks in Liaoning Province produces millions of tons of steel a year.

Major industries

Steel Price and Chinese Demand

In the early 2000s, steel prices worldwide soared, fueled in a large part by demand from China. Prices more that doubled to a peak o $700 a metric ton in August 2004 from $300 in January 2003. By 2005, the boom was over. There was an oversupply and prices plunged 40 percent from their high and there were worries about a long-term glut and overcapacity.

China’s capacity for steelmaking increased from 100 million in 2000 to 250 million tons in 2004. Ths in turn has caused increased demand for materials used in steelmaking: scrap metal, iron ore, pig iron, coke and coal, lime and dolomite. The price of iron ore rose for more than 70 percent for fiscal 2004-2005 — the first tine in history such a dramatic rise was recorded. Increases in steel production are also causing demand for more energy..

The increases were driven in part by global demand for high-end automotive steel. Steel companies built mills to supply automakers and their suppliers. Shortages of steel and unprecedented high steel price forced Nissan to temporarily suspend operations at some of its plants.

In December 2005, China announced that it would limit steel production to 400 million metric tons a year in the next five years to slow expansion that has led to a glut and driven up raw material prices.

During the global recession in 2008 and 2009 China tried to use its position as world’s biggest steelmaker and consumer of iron ore to win deals for iron ore price cuts following two hikes of more than 100 percent. Iron ore producers gave Japanese and South Korean mills a 33 percent cut but the Chinese wanted deeper reductions than that.

Japanese, Chinese and South Korean steel mills have been hurt by the decision of Vale SA, the world’s biggest iron ore supplier, to break a 40-year tradition in March 2010 of setting annual prices with Asian steel mills and instead signing price increases on shorter-term contracts, a move that came about as a result of Chinese demands.

Jotun paint factory

Chinese Steel Companies

As of 2005, China’s 264 steel makers supplied a third of the world’s steel. The trend in he future is one of consolidation so that Chinese steelmakers can compete with global giants like ArcelorMittal. The Chinese government hopes that China’s top 10 steelmakers account for half the country’s output in 2010 and 70 percent by 2020.

In July 2004, China announced a plan to consolidate the steel industry by forcing steel mills to merge and shutting down small, polluting furnaces. The plan was to reduce the number of steel makers from 260 to two, with a capacity of 300 million metric tons a year. This way steel companies would less likely be taken over by foreign companies and they would have the clout to dictate the terms with raw material suppliers and buyers.

In December 2009, the three largest Chinese steel mills — the large Tangshan Iron and Steel and smaller, Chengde Xinxin Vanadium and Titanium and Handan Iron and Steel — agreed to merge, creating the largest listed steel company in China. The three firms are located in Hebei Province and are part of the Hebei Iron and Steel Group, which has a production of 31 million tons, compared to Baosteel’s 29 million tons.

Baosteel, See Below

Anshan Iron and Steel (Ansteel) is China’s largest steelmaker. In 2005, the company was created through a merger of Anshan Iron & Steel, China’s No. 2 steelmaker, and Bexi Iron & Steel, China’s No. 5 steelmaker. It has an output of around 20 million tons of steel a year.

In recent years there has been a wave of mergers and aquisitions, so much so it is hard to keep track of what is what and who is who. In 2005, Wuhan Iron & Steel, China’s third largest steel maker at the time, announced it would merge with Liuzhou Iron & Steel, based in the southern province of Guangxi. It has an output of around 10 million tons and a capacity of 20 million tons of steel a year.

Foreign steel companies look hungrily at Chinese steel companies because of their cheap labor, cheap prices and access to hungry Chinese markets. In January 2005, there was some talk that ArcelorMittal, , the world’s biggest steelmaker, would purchase 49 percent of Bautou Iron & Steel, its second acquisition in China. It has stakes in Hunan Valin Steel and Laiwu Steels. In July, 2005, the government barred over seas producers from taking majority stakes in Chinese mills.

Chinese steel companies are increasingly spreading their influence overseas. Shougand, China’s second largest steel maker in term of income, mines iron ore in Peru and plans yo the same in Brazil and Australia. Sinosteel is a Chinese metals giant. In March 2008 it tried to buy Australian iron or producer Midwest Corporation with a hostile bid of $897 million.

ArcelorMittal, the world’s largest steel maker, has stakes in three Chinese steelmakers. In planned to take a 70 percent stake in the Chinese steelmaker Oriental for around $1 billion but the plan was abandoned after Chinese antitrust regulators failed to approve the deal. ArcelorMittal then said it would settle for a 30 percent stake.

Yangtze factory

Baosteel

Shanghai Baosteel Group (Baoshan Iron & Steel) is China’s largest steel company, the 6th largest mainland Chinese company by market value and the 6th largest steel maker in the world. It produced 22.73 million tons of steel and had sales of $21.5 billion in 2005. In 2004 it made 21.4 million tons. By contrast Mittal made 59 million tons. Arcelor-Mittal makes over 110 million tons.

Baosteel has making deals with foreign rivals and making domestic acquisitions in an effort to fend off foreign takeovers. It has a joint venture with Nippon Steel, the largest steelmaker in Japan. Nippon Steel has expressed interest in purchasing a stake in Baosteel and plans to build a cold rolled steel plant with Baosteel that will come into production in 2005. In July 2003, Arcleor, the world’s second largest steelmaker, said it would invest $800 million is a the Baoshan and Nippon joint venture. Posco has also expressed interest in investing in Baosteel. Baosteel sells its shares in New York.

Shanghai Baosteel Group is led by a woman Xie Qihua. She was ranked by Fortune magazine as No. 2 in the 2005 list of “50 Most Powerful Women in Business” in the world. Women make up 20 percent of the company’s workforce.

In March 2009, Shanghai-based Baosteel spent $295 million for 56 percent of Ningpo steel, another step in the government-backed consolidation of the steel industry.

Tools and Parts Industries in China

Copper parts worker

Chinese companies are now beginning to export auto parts, Many foreign auto parts makers are facing the choice of shifting some of their operations to China and becoming less competitive.

As of 2005, thee were 4,171 auto parts makers in China. Wanxiang, which specializes in universal joints and brake discs, was ranked No.1 with revenues of $2.6 billion. Wamxiang Group bought 21 percent of U.S. brake makers Universal Automotive. It also has a major stale in components maker Rockford Powertrain.

Delphi. the world’s largest auto parts maker, had 11 plants supplying Chinese joint ventures and a research center in China. In October 2005, it filed for bankruptcy, resulting in massive lay offs and plant closures. Competition from China was cited as one of the reasons for the move. Among those interested in Delphi’s asset was Wanxiang.

These days Japanese tool and die makers are under a lot of pressure from low-cost competitors in China, who in many cases use computer aided devices and Japanese blueprints to produce goods at half the cost as the Japanese. The number of tool and die companies in Japan has fallen from 12,038 in 1996 to 11,330 in 2003.

Shipbuilding in China

The shipbuilding facilities on Changxingdao Island near Shanghai were finished in the fall of 2008. It is one of the worlds’s largest shipbuilding facilities,

China is quickly growing into the world’s largest shipbuilding yard. In Dalian, companies are making 300,000-ton oil tankers for Danish shipping companies and offshore drilling platforms for U.S. oil drillers.

In 2007, China had 23 percent share of the global ship producing industry, up from 18 percent in 2006, with Japan and South Korea each having roughly a 35 percent share. China hopes to become the world’s largest ship producers by 2015. In terms of new orders China was No1 in 2007 with 98.5 million deadweight tons, 42 percent of the global total.

Chinese shipbuilding owes is success to low labor costs, support of the government in the building ship yards, ports and other infrastructure, the global shipping boom and the fact that the booming Chinese economy and export industry generates demand for more container ships.

The reputation of Chinese shipbuilding quality is improving. One industry analyst told AFP, “Chinese companies are very concerned about safety and the environment. They are large and extremely professional enterprises, and they’re just as good as their counterparts in the United States and Norway. There quality is still not on par with Japan and South Korea but they are considerably cheaper.

Shipbuilding in China is dominated two huge shipbuilding companies. One of them, Dalian Shipbuilding, is the 8th largest shipyard in the world. In 2007, it delivered 32 vessels, with a total of 3 million deadweight tons. Its order books are filled through 2011. In recent years a number of smaller shipyards have sprung up. As of 2008, there were over 3,000 small ship yards, up from just 350 in 1998. Many are run by local governments, private groups or are joint ventures.

Some American military analysts see China’s increased shipbuilding capability and sophistication as a threat in that Chinese shipbuilders are quickly gaining the know-how and ability to make large and advanced warships such as aircraft carriers.

Chemicals, Glass and Cement in China

entrance to PLA factory

There are around 80,000 chemical factories in China It is often not clear exactly what they make. They are among China’s worst polluters. Some of them also produce counterfeit drugs and fake drug ingredients.

There are 20,000 petrochemical factories in China with 10,000 along the Yangtze River basin and 4,000 on the Yellow River basin. A government study found that 81 percent of China’s chemical plants are dangerously close to population centers.

In 2010, Sinochem was among the companies that expressed interest in acquiring Canada’s Potash Corp., the world’s largest producer of fertilizer, which BHP Billiton offered to buy for $39 billion in a hostile bid.

A number of foreign chemical and oil companies are building petrochemicals plants in China. BASF, with its partner Sinopec, is building a $2.9 billion plant on Nanjing that can produce 1.7 million tons of chemical products a year. BP is building a plant in Shanghai that can produce 900,000 tons of chemicals. Shell is building a plant in Guangdong that can make 800,000 tons of chemicals. Exxon plans to build a plant in Fujian Province. Mitsubishi is building a plant Zhejiang Province that produces ingredients to make polyester.

China makes 44 percent of the world’s cement. Cement production is a major creator of greenhouse gases. Anhuo Conch Cement is China’s largest cement maker. It is base in Whu.

China makes half the world’s flat glass.

Construction in China

China is currently experiencing a massive construction boom. In recent years there has been a frenzy a shopping center, office tower and apartment building. Whole cities seem "sheathed in bamboo scaffolding and entire hills have bulldozed away for bricks." In Beijing alone in 2006, 92.9 million square meters of office and residential space was under construction — the equivalent of three Manhattans.

Each year for the past few years China has produced 75 billion square feet of commercial and residential space, more than the combined space of all the shopping ,malls and strip malls in the United States

Construction accounts for 27 percent of China’s total energy consumption. As of 2006, construction of factories and infrastructure accounted for 41 percent of GDP and about half the economic growth.

Chinese construction companies are engaged in projects in Saudi Arabia and all over the Middle East.

See Beijing, Shanghai, Infrastructure

Bamboo-scaffolding--Hong Kong

Image Sources: 1,4) University of Washington; 2)Landsberger Posters http://www.iisg.nl/~landsberger/; 3,7) China Lanor Watch; 5) Guardian, Environmental News; 6) Cgstcock: 8) Nolls China website http://www.paulnoll.com/China/index.html ; Wiki Commons

Text Sources: New York Times, Washington Post, Los Angeles Times, Times of London, National Geographic, The New Yorker, Time, Newsweek, Reuters, AP, Lonely Planet Guides, Compton’s Encyclopedia and various books and other publications.

Last updated April 2010